Reviews:

No comments

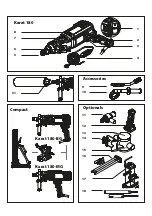

Related manuals for Karat 180-BG

RH26/36CVR

Brand: Felisatti Pages: 36

BQE303

Brand: Gasmate Pages: 16

Keystone Black JKS400BLK-LP

Brand: Jackson Grills Pages: 48

JA480

Brand: Jenn-Air Pages: 6

VANILLA 223.9988.000

Brand: Barbecook Pages: 120

576779

Brand: Festool Pages: 22

120SC - 225

Brand: Quackenbush Pages: 40

TEXAS

Brand: RUSTA Pages: 44

TPD23

Brand: Toyama Pages: 48

720-0732

Brand: KitchenAid Pages: 108

740-0781GH

Brand: KitchenAid Pages: 34

D300XT

Brand: SteelMax Pages: 37

BG06-200A

Brand: FCC BBQ Pages: 24

CC1416

Brand: ROYAL GOURMET Pages: 9

CD1824A

Brand: ROYAL GOURMET Pages: 19

GBQS250

Brand: Goldair Pages: 24

810-7600-S

Brand: Charmglow Pages: 52

810-7600-F

Brand: Charmglow Pages: 52