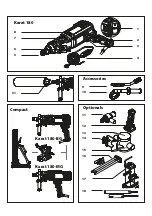

KARAT

®

180

US

OPERATING MANUAL KARAT® 180

5

gerous and must be repaired.

c) Disconnect the plug from the power source

and/or the battery pack from the power tool

before making any adjustments, changing

accessories, or storing power tools. Such

preventive safety measures reduce the risk of

starting the power tool accidentally.

d) Store idle power tools out of the reach of

children and do not allow persons unfamiliar

with the power tool or these instructions to

operate the power tool. Power tools are dan-

gerous in the hands of untrained users.

e) Maintain power tools. Check for misalign-

ment or binding of moving parts, breakage of

parts and any other condition that may affect

the power tool’s operation. If damaged, have

the power tool repaired before use. Many

accidents are caused by poorly maintained

power tools.

f ) Keep cutting tools sharp and clean. Properly

maintained cutting tools with sharp cutting

edges are less likely to bind and are easier to

control.

g) Use the power tool, accessories and tool bits

etc. in accordance with these instructions,

taking into account the working conditions

and the work to be performed. Use of the

power tool for operations different from

those intended could result in a hazardous

situation.

5) Service

a) Have your power tool serviced by a qualified

repair person using only identical replace-

ment parts. This will ensure that the safety of

the power tool is maintained.

b) For power tools with type X attachment,

where a specially preparde cord is needed

to replace the cord: if the supply cord of this

power tool is damaged, it must be replaced

by a specially preparded cord available

through a qualified service facilty.

FOR YOUR SAFETY

Please read and comply with these

instructions prior to the initial

operation of your device.

Retain these instruction manual for

future reference or for subsequent

possessors.

WARNING: Prior to the first start-

up, it is definitely necessary to read

the Safety instructions!

In case you do not adhere to this instruction

manual and the safety instructions, this may result

in damages on the device and cause dangerous

situations for the operator and other people. In

case of transport damage inform vendor imme-

diately.

SPECIAL TOOLS SAFETY

WARNINGS

Working safely with this machine is possible

only when the operating and safety informa-

tion are read completely and the instruc-

tions contained therein are strictly followed.

Before using for the first time, ask for a prac-

tical demonstration.

Before working on the machine

itself, pull the mains plug.

Wear safety glasses and

ear protectors when

impact drilling.

Wear light respiratory

protection and a hard

hat.

Be careful of hidden electrical lines

or gas and water pipes. Check the

working area, e.g., with a metal

detector.

Use auxiliary handle(s), if supplied

with the tool.

Loss of control can cause personal inju-

ry.