KARAT

®

180

US

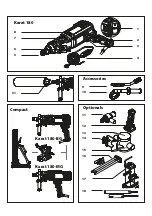

OPERATING MANUAL KARAT® 180

7

OPERATING CONTROLS

1

LED motor load

2

On/Off switch

3

Soft starter button

4

PRCD protective switch

5

Drilling shaft 1¼” male - ½” female

6

Water tap

7

Speed selection switch

8

Ventilation slots

9

Waterflow Indicator

10

Grip

11

Dry Drilling Kit* (optional)

12

2nd Back Grip* (optional)

13

Rubber cover

14

Fastening screw for water collecting ring

15

Water collecting ring* (option)

16

Shoulder pad* (option)

17

Connection plate for

11

,

12

and

16

*

(optional)

18

Pilot center drill for dry drilling* (optional)

19

Safety screw

20

Feed lever

21

Clamping lever for

22

22

Drill angle adjustment with scale

23

Stand Grip

24

Guide block clamping lever

25

Guide block for Karat 180

26

Base plate

27

Adjusting screws

28

Centering plate

29

Spindle nut

30

Screw assembly

31

Drill bit

*Not all of the accessories illustrated or described

are included as standard delivery.

SAFETY GUIDELINES

The definitions below describe the level of sever-

ity for each warning. Please read the operating

manual and pay attention to these symbols.

DANGER: Indicates an imminently

hazardous situation which, if not

avoided, will result in death or seri-

ous injury.

WARNING: Indicates a potentially

hazardous situation which, if not

avoided, could result in death or

serious injury.

CAUTION: Indicates a potentially

hazardous situation which, if not

avoided, may result in minor or

moderate injury.

NOTE: Indicates a practice not

related to personal injury which, if

not avoided, may result in property

damage.

INTENDED USE

The machine is intended for drilling into concrete

and reinforced concrete, when being used in con-

junction with diamond core bits for wet drilling

and a suitable water supply. Karat 180 can also be

used for dry drilling in masonry and other build-

ing materials with the dry drilling kit.

The vacuum pump is intended for the fixation of

drillstands Compact and Large. The pump is only

designed for sucking in air, and no other gases or

fluids.

For damage caused by usage other then

intended, the user is responsible.

BEFORE USE

When drilling through walls or floors, make

absolutely sure that there are no obstacles

in the adjoining rooms and cordon off the

building site. Prevent the drilling core from

falling.

Always use the correct supply voltage:

The

power supply voltage must match the informa-

tion quoted on the tool identification plate.

INITIAL OPERATION

Functional test for the PRCD protective

switch

WARNING: The ON/OFF switch 2

must be switched off, in order to

avoid unintentional starting of the

machine when carrying out the

functional test of the PRCD protec-

tive switch 4.

Before commencing work, check that the PRCD

protective switch is functioning properly: