R E P L A C I N G C A R T R I D G E S

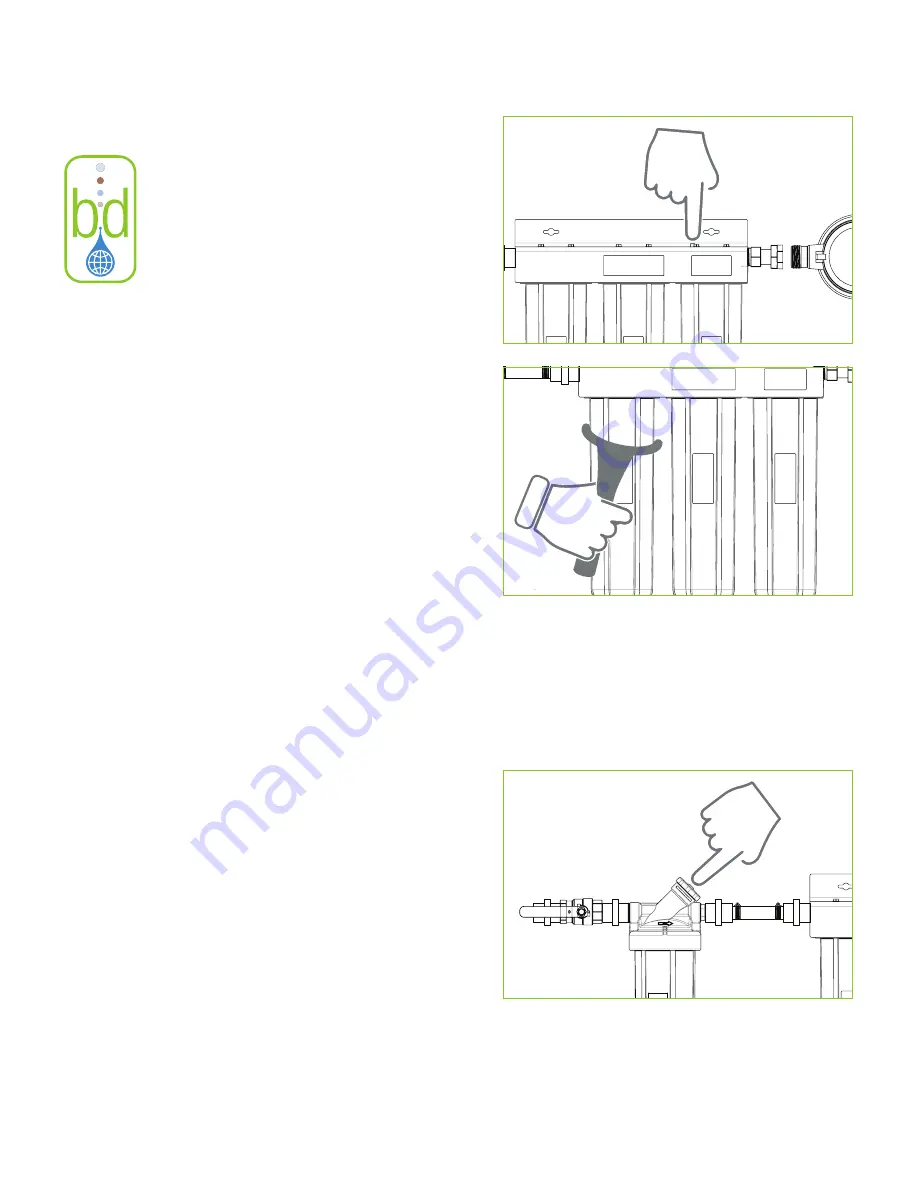

A.

Shut off the water supply - using the ball

valve connected to the left-hand (inlet) side of

the single stage housing.

B.

Release pressure – prior to attempting to re-

move the fi lter housing, the pressure will need

to be released. Push red pressure release but-

tons on each housing to release the pressure.

C.

Removing cartridges – using the wrench

provided, unscrew the appropriate housings

containing the cartridge(s) that you wish to

replace. This can be done by turning the car-

tridge housing counter clock-wise until loose.

Unscrew the cartridge housing carefully as it

will be fi lled with water and quite heavy. Re-

move and discard the exhausted cartridge.

D.

When removing the cartridge housing, it is

common for the O-ring seal to lift out of the

groove and, at times, may even stick to the

head of the fi lter housing. Do not lose the

rubber O-ring seal.

E.

Check the runner O-ring for nicks and use a

replacement if necessary. Rub Vaseline

TM

onto

the O-ring and place back onto the housing. Do

not wipe off residual Vaseline

TM

. Ensure O-ring

is well seated into groove.

F.

For convenience, the single stage brack-

et and housing containing the sediment fi lter

(stage one - 6001) can be bypassed individ-

ually. The valve lists options to “bypass” and

“fi lter.” Turn the valve clockwise to bypass the

water fl ow. Press the red pressure release in

the middle of the valve. Follow steps C. – E.

for replacement. Ensure that you twist the

valve counter-clockwise after the sediment

fi lter has been replaced. Failure to do so

will diminish the system’s function and the

following fi lters’ lifespan.

BDC6000BB

Certifi ed Nanotechnology Whole House Purifi cation System

9

Hel neu st 57