8

exhaust system shall be installed according to AS1668.1 and AS1668.2 interlocked to the gas supply. B&S

shall not be responsible for any unauthorized and/or non-compliant installations and will void the

warranty.

Combustible Surfaces

Clearances to combustible surfaces must be in accordance with AS/NZS 5601.1 -

Gas Installations

,

clause

5.12.4.5.

Install on a flat/level floor. Where the floor is not fire resistant, and fire resistant material shall be put

under the appliance which shall have a fire resistance rating at least equal to that of 10mm millboard. The

material shall extend at least 50mm beyond the edge of the appliance.

Leave a clearance of at least 150mm from nearest combustible material at either side or at the rear.

Leave clearance of at least 500mm from the front of the wok table for services.

Please refer to table 6.9 and 6.10 in AS 5601.1. clause 6.10.2.2 and 6.10.2.3. Table 6.10 (2013 version)

is given below. (Please refer to the latest version when released)

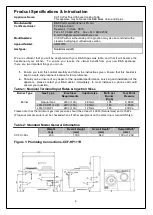

MINIMUM CLEARANCE AROUND COOKING SURFACE AREA

The clearance to combustible surfaces from commercial catering equipment shall be as specified in the

appliance manufacturer’s instructions and shall not be less than the clearance specified in the table below.

Cooking surface area

Minimum clearance in mm

A

Above the cooking surface of a gas appliance not covered

in table 6.9

600

B

Subject to C from a cooking surface area having an open

flame and no means of preventing cooking vessels from

overhanging the edge of the gas appliance

250

C

From the side of an open flame appliance where the

combustible surface is at least 100mm below a cooking

surface area

50

D

From a gas appliance flue way or rear of the gas appliance

with a splashback

50

E

From the rear or side of a gas appliance which is not an

open flame gas cooking appliance

50

Notes:

1. The cooking surface area is defined as being that part of the gas appliance where cooking normally

takes place and does not include those parts of the gas appliance containing control knobs.

2. These clearances do not apply where an adjacent surface is of a non-combustible material or is

combustible but protected with a fire-resistant material. The fire-resistant material may be covered by

ceramic tiles or stainless steel to meet appropriate requirements relating to health protection.

3. Care should be taken where a combustible surface is covered by a non-combustible material for

example, covering a combustible surface with stainless steel will not prevent heat transfer, and in

some circumstances hazardous situation could arise.

Gas Connection

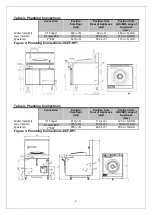

The gas connection is male 3/4

” BSP and is situated at the rear of the appliance below the main body

frame. The number of gas inlets corresponds to the number of wok rings the appliance is fitted with. The

inlet is to the ¾

” pipe located at the rear of the appliance.

This appliance is available in models for fixed installation or in models fitted with wheels/castors.

The appliance must be connected with rigid pipe as specified in AS/NZS5601. For fixed installation models

connect with 20mm copper tube and an Australian certified isolating valve.

For models fitted with wheels/castors an Australian certified stainless steel braided flexible hose of adequate

internal diameter must be used. The fitting of the hose must comply with the relevant sections of gas

installation code AS/NZS 5601. A restraining chain or wire must be fitted. We recommend a maximum length

of 1.5 m for the flexible hose. Wheels /castors are provided only on the rear supports of the unit while the

front section of the unit will still be on legs. In this way, the unit will stay in position without moving. An