9

5. Operating Instructions

1. Move the unit and choose the optimal distance between emitter and car body. The

optimal distance 12” to 14” inches.

2. Adjust the direction of the emitters. They should be aligned parallel to the car body.

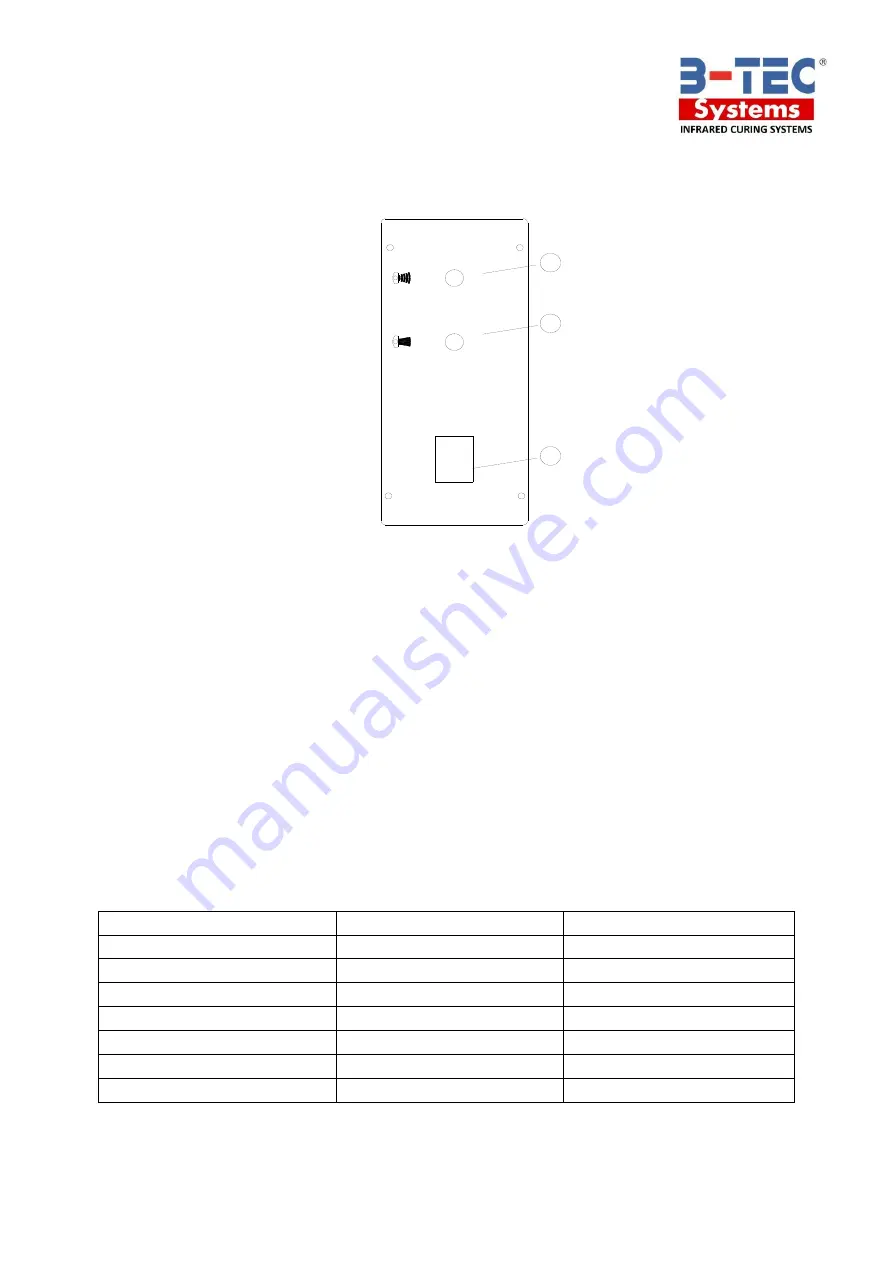

3. Adjust the timer button (1) to set half power / flash baking time.

4. Adjust the timer button (2) to set full bake / continuous time.

5. Turn on the power switch (3).

6. The machine stops automatically after the curing cycle has been completed. If you

want to continue using the unit, restart the machine after cutting off the power for 5

minutes.

7.

If you don’t want to use the stand and prefer to use hand, connect the Infrared head

directly to the power supply and turn on the power switch. In that situation there are

no time limits, no automatic stops and no half power facility.

5.1 Curing Times

All curing times are supplied as a guide only.

Paint type

Flash off

Full bake (Minutes)

Filler/Stopper

---

5-7

Primer

---

6-8

Hi-build

---

10-12

Solid-color

---

11

Clear coat

---

12

Waterborne primer

---

8-10

Waterborne basecoat

---

5

Note: We suggest that when curing high build primers and dark colors. You move back to 18”

and add 5 minutes to the bake time. If possible consult B-TEC SYSTEMS or your distributor

for the availability of a paint curing data sheet for your paint brand.

1

2

POWER

30

35 MIN

35 MIN

30

30

35 MIN

15

20

25

25

20

15

15

20

25

5

0

10

10

0

5

5

0

10

CONTINUOUS

FLASH

35 MIN

30

30

35 MIN

35 MIN

30

0

5

5

0

0

5

25

20

10

15

15

10

20

25

25

20

10

15

3

Summary of Contents for IR-B01

Page 1: ...Infrared Model IR B01...