5. MAINTENANCE AND TROUBLESHOOTING

No routine maintenance is required other than to keep the interior of the unit clean and free of dirt, moisture and

other contaminants.

The LS8000/2 consists of three main sub-assemblies. These are the enclosure with the antenna probe, the

transmitter module and the receiver card. The following troubleshooting guide will assist in determining how to

correct most of the problems, which may occur in the field. Review the installation and calibration procedures in

sections 3 and 4.

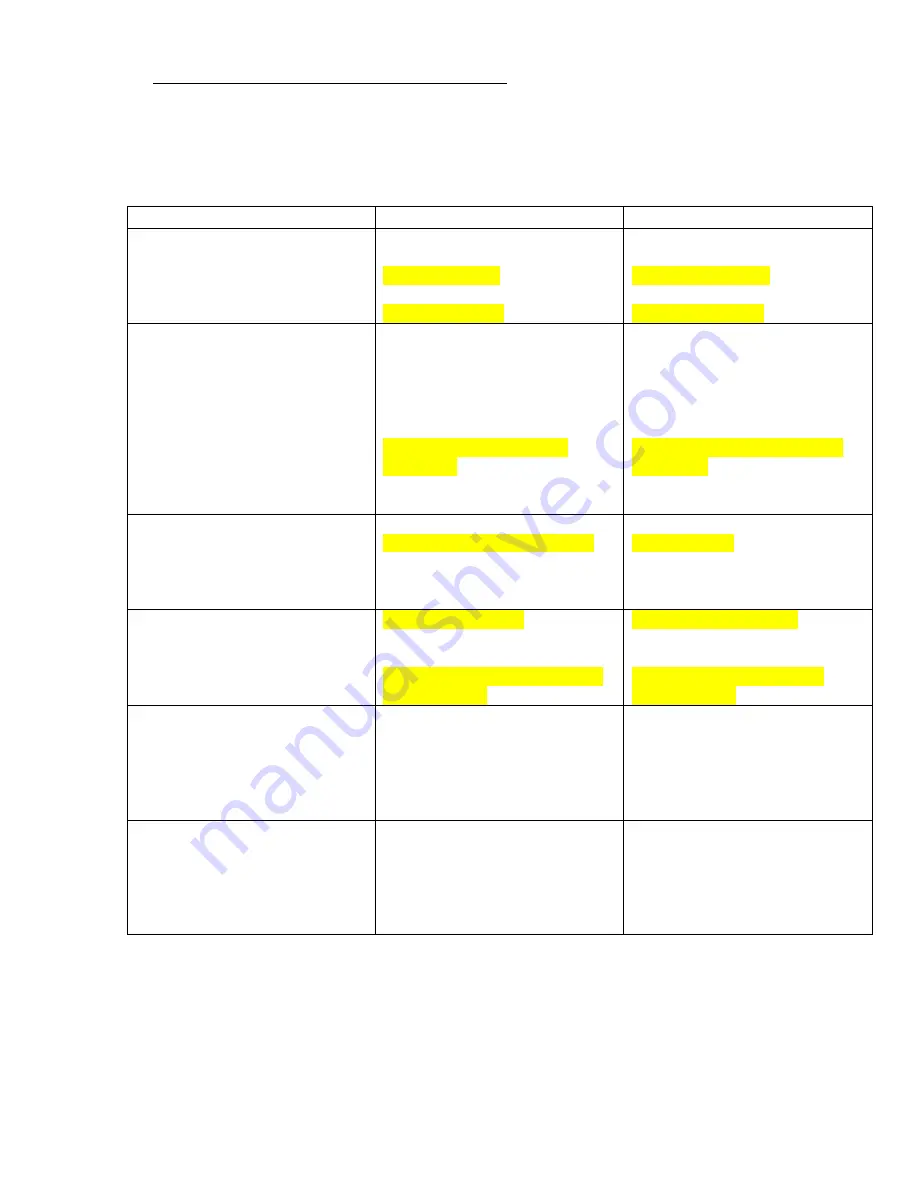

PROBLEM POSSIBLE

CAUSE SOLUTION

RED LED cannot be adjusted to

turn on.

Transmitter module not connected

to probe.

No power to unit.

Blown on board fuse.

Bad receiver card.

Plug transmitter into probe.

Check power to unit.

Replace fuse.

Repair/replace card.

RED LED remains on at all times

Antenna probe is shorted to case

or ground.

Shielded cable not correctly

hooked up.

Shielded cable broken or shorted.

Unplug module and position it so

that the bare end is not touching

anything. Turn calibration pot 25

turns CCW. LED should go out.

If so, repair, replace or clean

antenna probe.

Check shielded cable for proper

connection.

Check shielded cable for shorts or

open circuits.

Unit triggers when material

touches probe, but will not reset

when material recedes from probe

or unit and gives false alarm.

Improper mount of probe.

Improper calibration procedure.

Excessive material build-up on

probe.

Contact factory or dist.

See section 4C.

Perform “dirty probe calibration”:

Recalibrate with built up material

on probe. See section 4C.

Unit will not detect material.

Improper calibration.

Transmitter module not plugged

into probe.

Unit was calibrated with material

touching probe.

See calibration section 4.

Plug transmitter module into

probe.

Recalibrate without anything

touching probe.

Unit will not stay in calibration.

Poor grounding of transmitter

housing to vessel.

Provide secure ground connection.

Fluid must be grounded to

mounting nipple of probe.

Grounding rod may be necessary

for non-metallic or rubber lined

tanks.

Relay operates properly, but no

signal at terminals.

Burned or broken lands on

receiver printed circuit board.

Bad relay contacts.

Turn off power. Remove module

from housing and inspect lands on

printed circuit for damage.

Replace as necessary.

Replace relay or return for repair.

PLEASE CONTACT THE FACTORY OR YOUR LOCAL DISTRIBUTOR IF YOU

HAVE ANY QUESTIONS OR NEED ASSISTANCE.

14