4. CALIBRATION

PLEASE READ THE ENTIRE CALIBRATION PROCEDURE BEFORE CALIBRATING THE LS8000

.

If no time delay is required, turn the time adjustment pot completely CCW and set S1 down, S2 up. The

potentiometer has 20 turns and freewheels at the end of its travel without damage. You may hear “clicks” at the end

of travel.

A. Setting the Time Delay

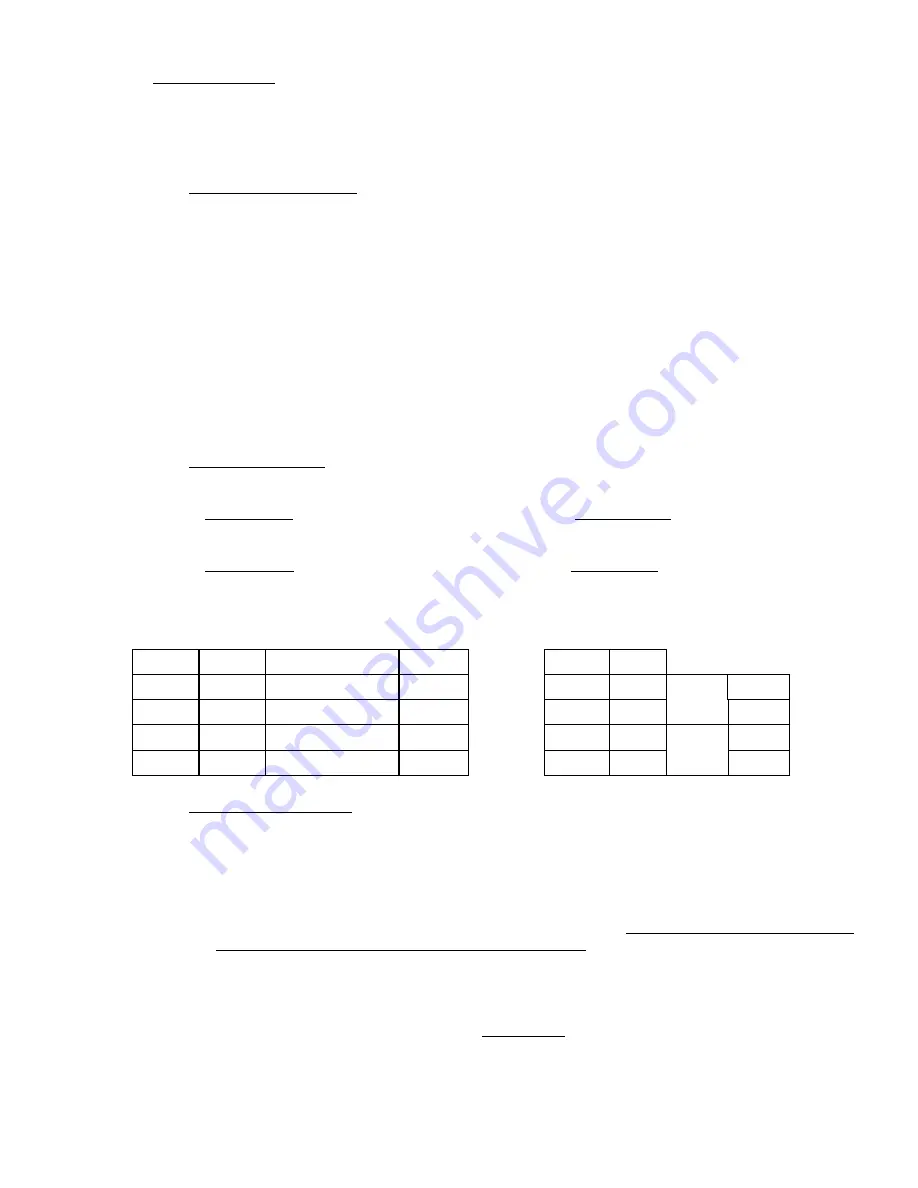

1) Setting the timing mode, either on delay or off delay, is done by positioning S3 and S4 as shown in the

chart below.

NOTE:

S3 and S4 also select fail safe high level (FSH) or fail safe low level (FSL).

2) Select the timing range using S1 and S2 as shown on the chart below.

3) Adjust the time adjustment potentiometer clockwise to increase time or CWW to decrease until the exact

time delay is reached. The test switch may be depressed to start the timing when checking timing

sequence.

NOTE:

For long timing ranges you can set the timer for a shorter range, then

change the range switches (S1 and S2) to increase the time. For example, the desired

time delay is 15 minutes. This is equal to 900 seconds. By setting S1 down and S2 up

and adjusting the timer to approximately 28 seconds, the ratio on this range is 1. To

increase this range by 32, move S1 up and S2 up. 32x28 seconds equals approximately

15 minutes.

B. Fail Safe Selection

The fail safe feature provides a “false alarm” in case of power outage or major component failures. When

properly selected, the fail safe feature can protect equipment or alert you of a unit failure.

1) Fail Safe High (FSH) means that the relay is energized when NO PRODUCT is touching the probe. The

green led indicates relay status and is on when the relay is energized. When product comes into contact with

the probe, the relay is de-energized.

2) Fail Safe Low (FSL) means that the relay is energized when PRODUCT IS touching the probe.

NOTE: Due to the wide variety of applications and possible control or alarm functions, the proper fail safe

selection will depend on your circumstances. Please call your distributor or the factory if you need assistance.

TIMING RANGE

FAILSAFE TIMER MODE

S1 S2

TIME

RATIO

S3 S4

DN

UP

1/8 sec - 35 sec

1

UP UP ON FSL

UP

DN

1/2 sec - 140 sec

4

DN UP

DELAY

FSH

UP

UP

4 sec - 18 min

32

DN DN OFF FSL

DN

DN

32 sec - 2 hrs

260

UP DN

DELAY

FSH

C. Sensitivity Calibration

The LS8000 should be calibrated when no material is touching the probe and when the unit is installed where it

will be used.

1) Observe the red LED. If it is on, go to step 3.

2) If the red LED is off, turn the sensitivity adjustment potentiometer CW until it comes on.

3) Turn the sensitivity adjustment pot CCW until the red LED just goes out and continue to turn the pot CCW

at least ¾ of a turn. This sets the unit to its maximum stable sensitivity. If in your application this is too

sensitive, you can turn the sensitivity adjustment pot further CCW. Always bring the product into contact

with the probe after calibration to assure proper performance.

Note the green LED indicates relay status. The relay is energized when the green LED is on.

SPECIAL CALIBRATION NOTES:

For some products, the LS8000 can be calibrated with product touching the probe. To do this, turn the

sensitivity adjust pot CW until the red LED just comes on and continue CW for ¼ to ½ of a turn.

ALWAYS CHECK TO SEE IF THE UNIT RESETS IN THE ABSENCE OF PRODUCT.

10