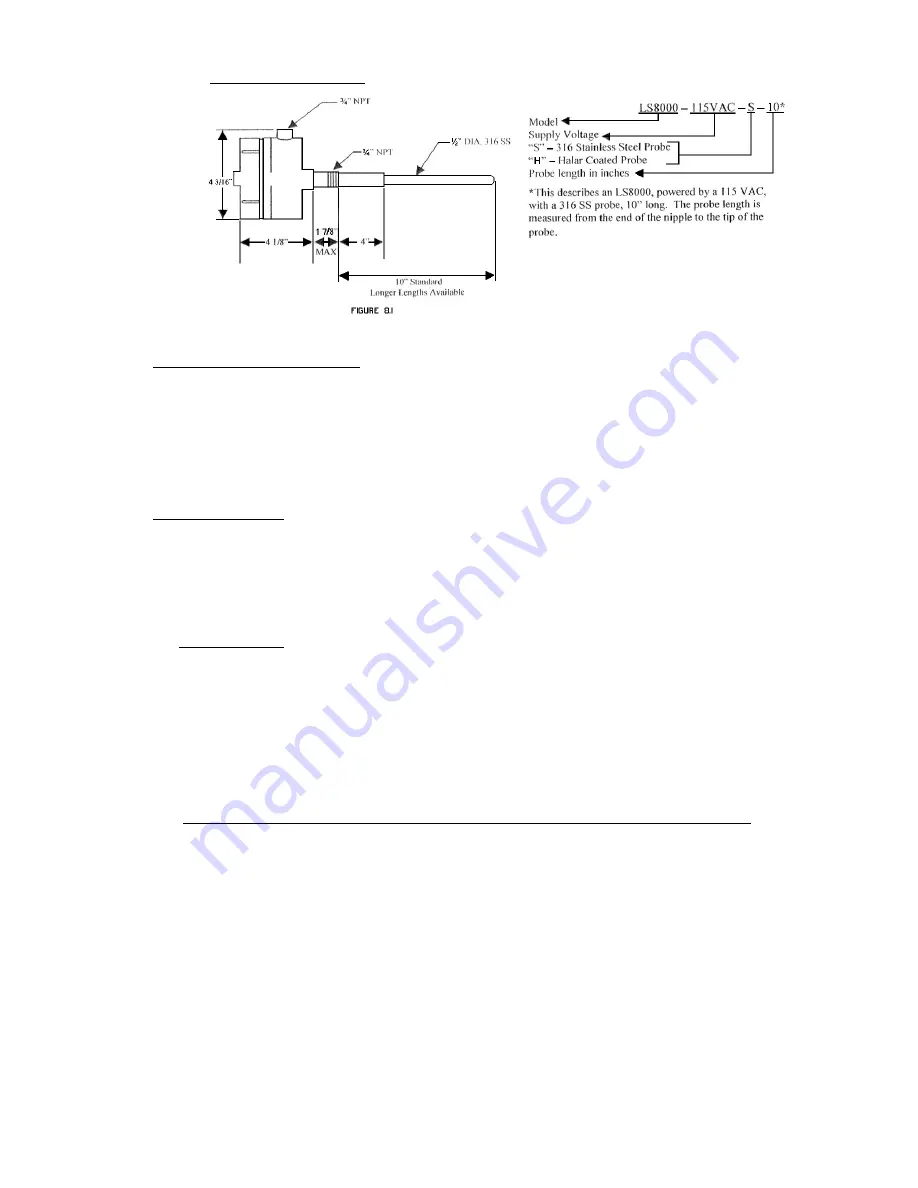

C. Ordering Information

2. THEORY OF OPERATION

The LS8000 employs a radio frequency (RF) balanced impedance bridge circuit to detect if the probe is in

contact with the material that is to be sensed.

When material is not in contact with the probe, the bridge is balanced by turning the adjustment pot to find the

threshold where the red led goes out.

When material is in contact with the probe, the bridge becomes unbalanced and the comparing circuit realizes

the change. This causes the relay to change state.

3. INSTALLATION

*

CAUTION: ALL INSTALLATION AND WIRING MUST CONFORM TO NEC

AND ALL OTHER LOCAL ELECTRICAL CODES. TAKE SPECIAL CARE IN

OBSERVING HAZARDOUS AREA SAFETY PROCEDURES. WE ASSUME NO

LIABILITY FOR IMPROPERLY INSTALLED OR WIRED UNITS

.

A. INSPECTION

After unpacking the LS8000, visually inspect the unit for any damages.

Please advise the factory or your local distributor of any damage.

A complete unit should consist of the following:

1. An explosion proof enclosure with probe attached

2. A transmitter module in the explosion proof enclosure

3. The LS8000/R receiver card

4. A plastic snaptrack to mount the receiver card

B. PHYSICAL INSTALLATION OF TRANSMITTER MODULE AND PROBE

1) The LS8000 is installed into the vessel wall using a ¾” NPT connection.

This can be either a threaded coupling or a tapped entry such as a flange.

2) The teflon insulator should always extend at least 2” through the vessel wall.

3) Always check for physical room around the location you have chosen to allow for installation. Allow 2 ¾”

turning radius to screw the probe in and clearance above for the length of the probe.

4)

CAUTION:

Always take the necessary safety precautions when cutting or welding in the

coupling for the LS8000.

a) Tag and lock out the electrical power to the equipment that services the vessels.

b) Check liquid or dry powders that create a gas in the vessel for oxygen as well as the explosion factor.

(All dust will explode.)

c) Vessels that are cross vented have to be isolated.

5) Screw the LS8000 into the connection provided. In dry material application, no sealant on threads is

required. In liquid, teflon or a good pipe thread sealant may be used.

2