Decorative Stitching

111

3

— — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — — —

f

Sew with the center of the presser foot aligned

along the center of the two pieces of fabric.

g

After sewing is finished, remove the paper.

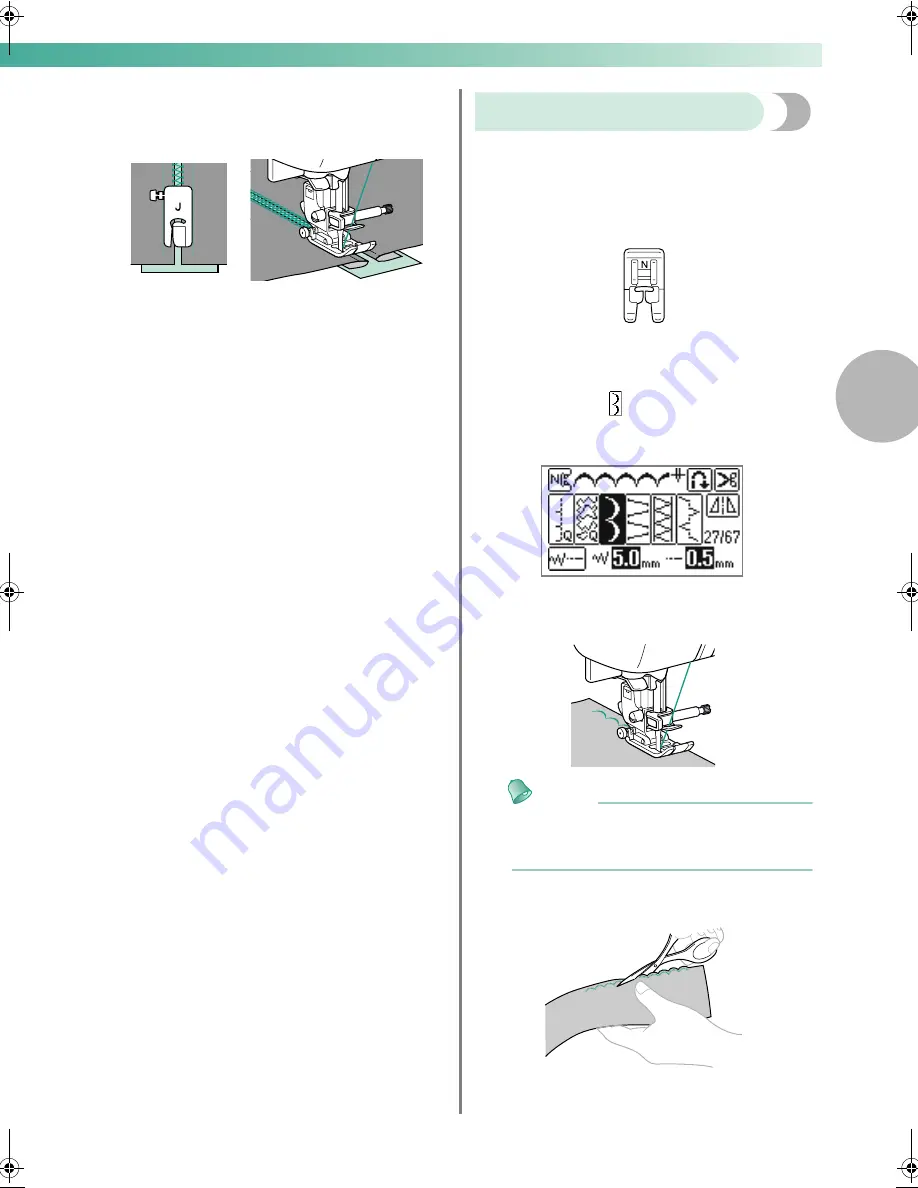

Scallop stitching

The wave-shaped repeating pattern that looks like

shells is called "scalloping". It is used on the collars of

blouses and to decorate the edges of projects.

a

Attach monogramming foot "N".

• For details on replacing the presser foot, refer

to "Replacing the presser foot" (page 43).

b

Select stitch

27

.

• For details, refer to "Selecting stitching"

(page 49).

c

Stitch along the edge of the fabric, making sure

not to sew directly on the edge of the fabric.

Memo

z

For better results, apply spray starch onto the

fabric and press with a hot iron before it is

sewn.

d

Trim along the stitches.

Be careful not to cut the stitches.

0711-0120-C-combo_E.book Page 111 Tuesday, August 26, 2008 2:43 PM

Summary of Contents for A-LINES Sofia BL137A

Page 1: ......

Page 16: ...14...

Page 70: ...SEWING BASICS 68...

Page 156: ...154 EMBROIDERY...

Page 174: ......

Page 175: ......