26

Trouble Shooting

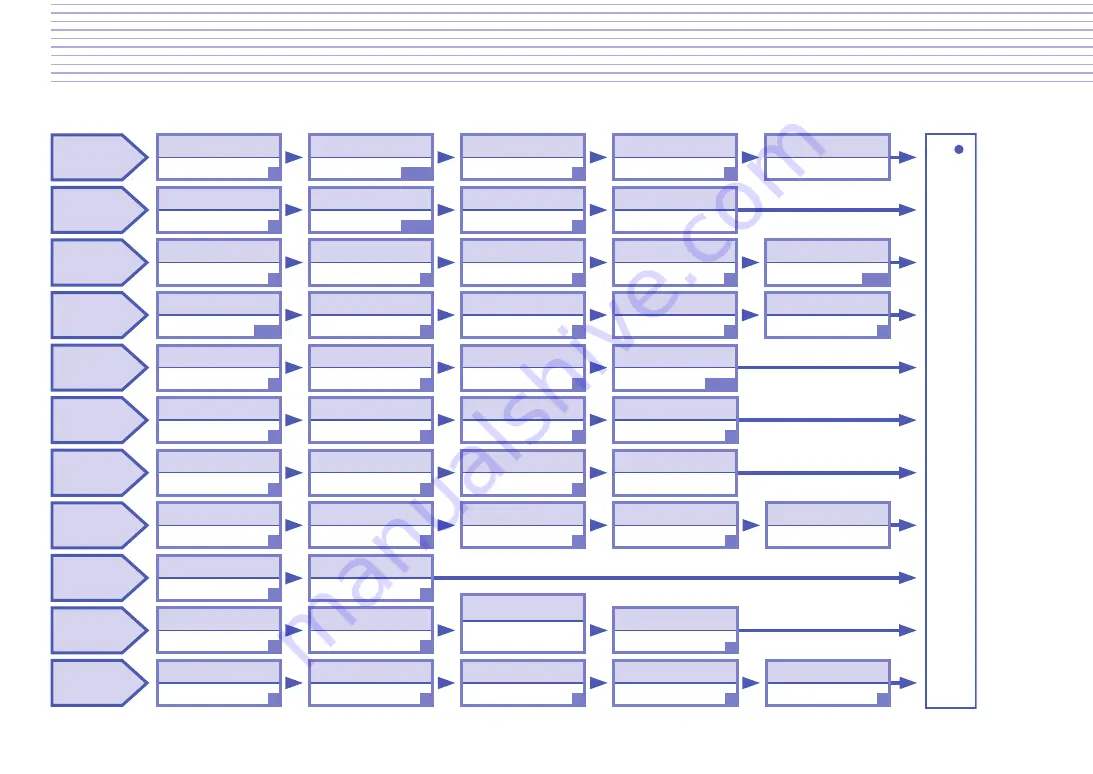

Before taking your sewing machine in for service, check the following chart.

✽

14-16.25

Thread

Breakage

Upper threading is not

threaded correctly.

Re-thread machine

properly.

Thread is getting tangled.

Re-thread machine.

Clean bobbin case and under

needle plate. Oil the machine.

Upper thread tension is

too high.

Reduce tension.

Improper fabric/needle/

thread combination.

See chart on p.17 for the right

needle to use with your

fabric and thread.

Bobbin case may be scratched.

Remove needle plate and

check bobbin case.

Bobbin Thread

Breakage

Skipped

Stitches

Fabric

Puckers

Fabric Won’t Feed

Properly or Irregular

Stitches

Loop in

Seam

Needle

Breakage

Sewing Machine

Doesn’t Run

Machine is

Noisy

Automatic Needle

Threader Doesn’t

Work

Thread Cutter

Doesn’t Work

Bobbin thread is not passing

correctly from bobbin case.

Needle is not inserted

correctly.

Wrong needle.

See chart on p.17 to choose the

needle that best fits your

fabric-thread combination.

Threading is incorrect.

Wrong needle for the fabric

and thread you are using.

See chart on p.17 to choose the

needle that best fits your

fabric-thread combination.

Stitch length is too short.

Pressure of sewing foot is

too weak.

Increase foot pressure.

Upper threading is

incorrect.

Thread is not passing through

bobbin case correctly.

Reset bobbin case.

Needle is not attached

correctly.

Wrong needle.

Change to correct needle.

The power isn’t on.

Machine’s not plugged in.

Check to make sure the

machine’s plugged in.

The area under the needle

plate needs to be cleaned.

Needle is not in the

highest position.

Needle is not properly

inserted.

Reinsert bobbin

properly.

Bobbin tension is too high.

Reduce tension.

Bobbin case may be scratched.

Remove needle plate and

check bobbin case.

Reinsert.

Machine is not threaded

properly.

Re-thread machine.

Re-thread machine.

Needle is bent, or tip is

dull.

Change needle.

Clean feed dog and bobbin

case. Oil the machine.

Area under needle

plate needs to be cleaned.

Upper thread tension is

too high.

Reduce tension.

Reduce tension.

Bobbin tension is too high.

You’re sewing a lightweight fabric with

feed dog in heavyweight position.

Adjust feed dog.

Sewing heavyweight fabric with

feed dog in lightweight fabric

position.

Adjust feed dog.

Re-thread machine. Clean needle

plate and bobbin case.

Thread is getting tangled.

Adjust stitch length.

Re-thread machine

properly.

Improper fabric/needle/

thread combination.

See chart on p.17 for the right

needle to use with your

fabric and thread.

You’re pushing or pulling

the fabric.

Do not push or pull fabric.

Improper fabric/needle/

thread combination.

See chart on p.17 for the right

needle to use with your

fabric and thread.

Reattach.

Turn the power on.

The foot controller has

come unplugged.

Reattach foot controller.

Clean feed dog and

bobbin case.

Turn handwheel to

raise needle.

Wrong needle for the

thread you’re using.

See chart on p.17.

Hook of needle threader doesn’t

pass through eye of needle.

Check to make sure the hook isn’t

bent. Needle may need to be raised

to the highest position.

Using the automatic needle

threader incorrectly.

Check the use of the auto-

matic needle threader.

Reinsert. Set needle to highest

position in chamber.

Wrong needle.

See chart on p.17 to choose the

needle that best fits your

fabric-thread combination.

Needle is bent, or tip is

dull.

Change needle.

Area under needle plate

needs to be cleaned.

Clean feed dog and

bobbin case.

Upper threading is

incorrect.

Re-thread machine.

If you still cannot find the problem, please take your sewing machine into your nearest

authorized Baby Lock retailer for repair.

Thread is getting tangled.

Re-thread machine.

Clean bobbin case and

under needle plate.

15

14

11

8

15

11

8

25

Machine is out of oil.

Oil the machine.

25

8

11

14-16

17

17

9

14

11

8

17

17

17

17

11

17

10

17

17

8

Machine is out of oil.

Clean and oil the

machine.

Contact your authorized

Baby Lock retailer.

25

The safety device has been

activated.

11

17

25

17

25

16

15

10

14-16

14-16.25

14-16.25

Upper thread does not run

through the take-up spring.

Pass thread through the

take-up spring correctly.

15