SEWING THE STITCHES

U

tili

ty

S

tit

ch

es

153

3

e

Gently hold the end of the upper thread,

and then press the “Start/Stop” button to

start the machine.

→

Once sewing is completed, the machine

automatically sews reinforcement stitches, and then

stops.

Bar Tacks

Use bar tacks to reinforce areas that will be subject

to strain, such as pocket corners.

a

Select .

b

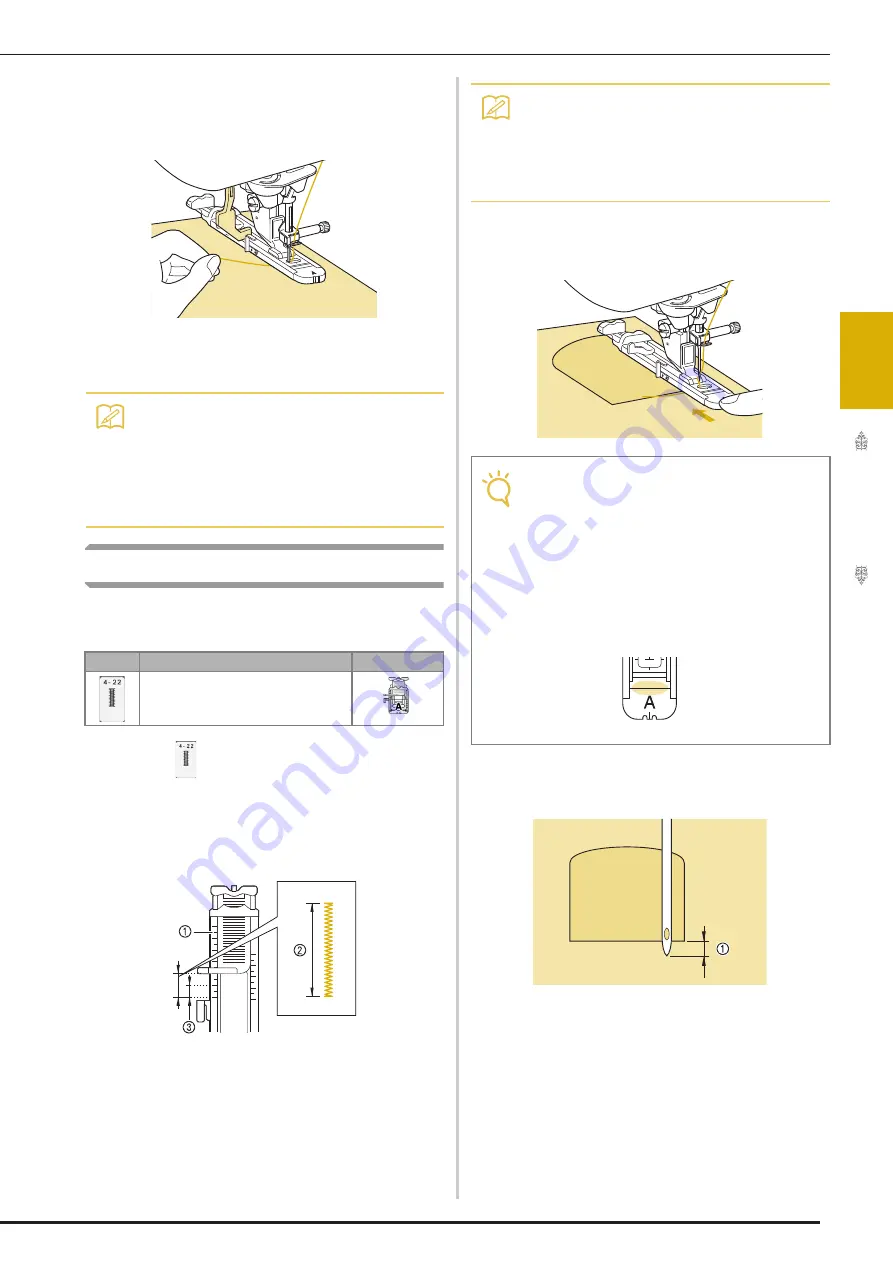

Attach buttonhole foot “A” and set the

scale to the length of the bar tack you wish

to sew.

a

Presser foot scale

b

Completed length measurement

c

5 mm (approx. 3/16 inch)

c

Set the fabric so that the pocket moves

toward you during sewing.

d

Check the first needle drop point and lower

the presser foot.

a

2 mm (approx. 1/16 inch)

Memo

• If automatic thread cutting is turned on

before you start sewing, both threads are

automatically cut after the reinforcement

stitches are sewn. If the fabric does not feed

(for example, because it is too thick),

increase the stitch length setting.

Stitch

Stitch name

Presser foot

Bar tack

Memo

• Bar tacks can be between 5 mm (approx.

3/16 inch) and 28 mm (approx. 1-1/16

inches). Bar tacks are usually between 5

mm (approx. 3/16 inch) and 10 mm (approx.

3/8 inch).

Note

• Pass the thread underneath the presser

foot.

• Slide the outside frame of the buttonhole

foot backward as far as possible as shown

in the illustration, making sure that there is

no gap behind the part of the foot marked

“A”. If the buttonhole foot is not slid back as

far as possible, the bar tack will not be sewn

to the correct size.

Summary of Contents for Destiny II

Page 1: ...XF9969 1011 Cover1 4 C M Y K...

Page 2: ......

Page 9: ...IMPORTANT SAFETY INSTRUCTIONS 7...

Page 80: ...NEEDLE CALIBRATION USING THE BUILT IN CAMERA 78...

Page 168: ...SEWING THE STITCHES 166...

Page 188: ...COMBINING STITCH PATTERNS 186 Press Press...

Page 196: ...USING THE MEMORY FUNCTION 194...

Page 198: ...XF9969 2012...