Left or right needle positions can be used for 2-thread

serging.

See machine threading illustrations on page 26.

1. Place the left needle thread on far left spool pin (or right

needle thread on second from left spool pin) and bring

the thread end through the telescopic thread guide

directly above the spool of thread. Bring the thread

through the top thread guide that is normally used for

the upper looper (3rd from left), and down the front.

Then take the thread to the left and thread the machine

as you would for the needles in their normal position.

(see illustration on page 26 for correct threading).

2. Using the needle threader, thread the eye of left or right

needle. (see page13 for threading of needles)

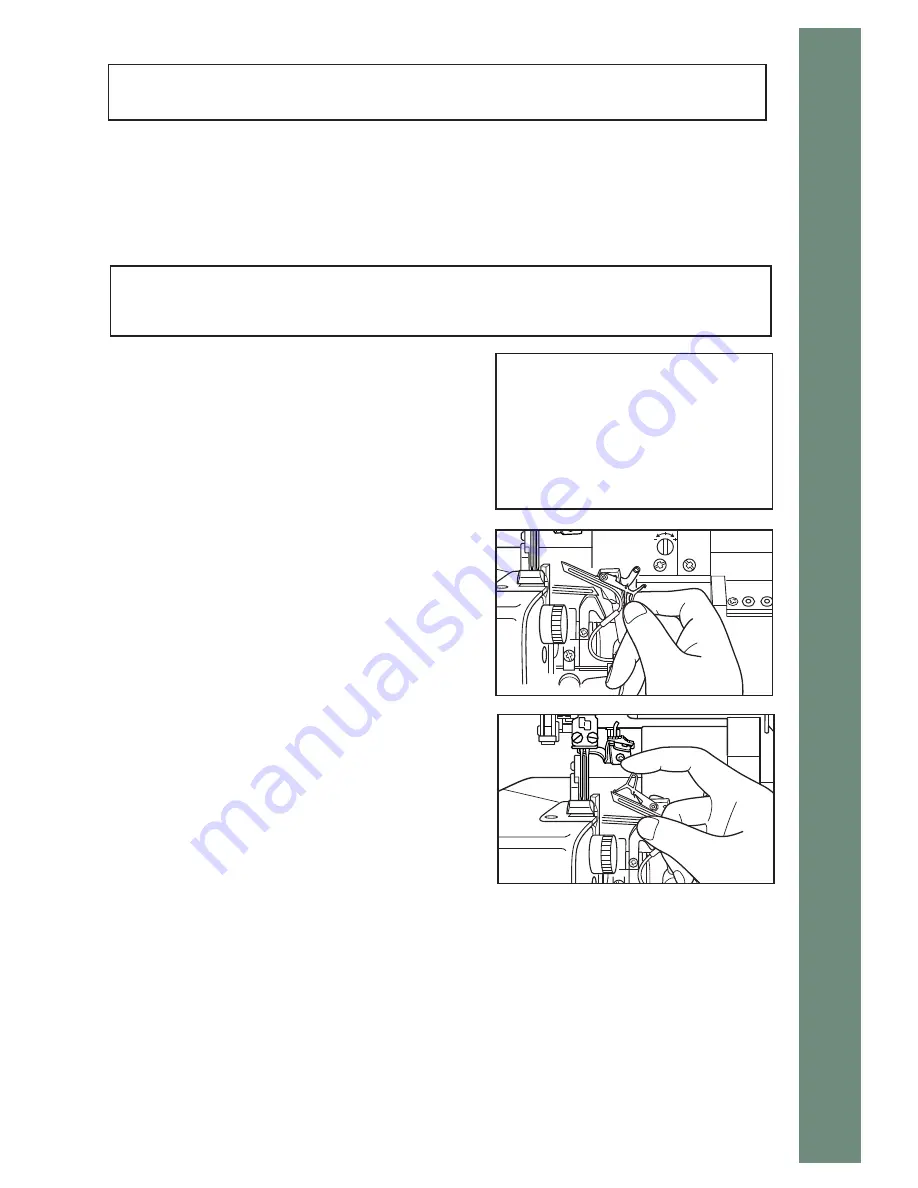

3. Rotate the handwheel to bring the upper looper into

position to attach the subsidiary looper. Rotate the

subsidiary looper up and to the left (fig.B) then slip the

end into the upper looper eye. (fig.C) Close the cutting

blade cover and front cover.

4. Unlock the machine to expose the thread. Using your

tweezers, pull the thread out of the tubular looper at the

lower end of the looper tube. Bring the thread up to the

large thread guide below the face plate and to the left

under the square guide. Bring the thread up and over

the take-up lever slot, down and into the last thread

guide above the overlock needles.

5. The needle and lower looper threads should overcast

evenly on the cut edge of the fabric.

6. Rotate the handwheel to bring the upper looper to its lowest position. Rotate the subsidiary looper up and

to the left (fig. B) then slip the end into the upper looper eye (fig. C). Close the blade cover and front cover.

7. The needle and lower looper thread should overcast evenly on the cut edge of the fabric.

Note:

The blade cover has been removed in photos B and C for a clear view. You do not need to remove

the blade cover.

2

T

R

Å

D

S

O

V

E

R

L

O

C

K

25

2-Thread Overlock

Converting from 3-Thread Overlock

to 2-Thread Overlock

A

B

C

The 2-thread function provides an economical and less bulky means of overedging all fabrics. The

standard 2-thread overlock is the same as a 2-thread flatlock stitch.

When sewn with specialty threads, 2-thread sewing makes decorative seams and edges for activewear,

children's clothing , ruffles, and hemlines.

Summary of Contents for imagine BLE1AT-2

Page 1: ...Model BLE1AT 2 Instruction Manual Vol 1 0...

Page 54: ...EI E BLE1AT 2 TA...