18

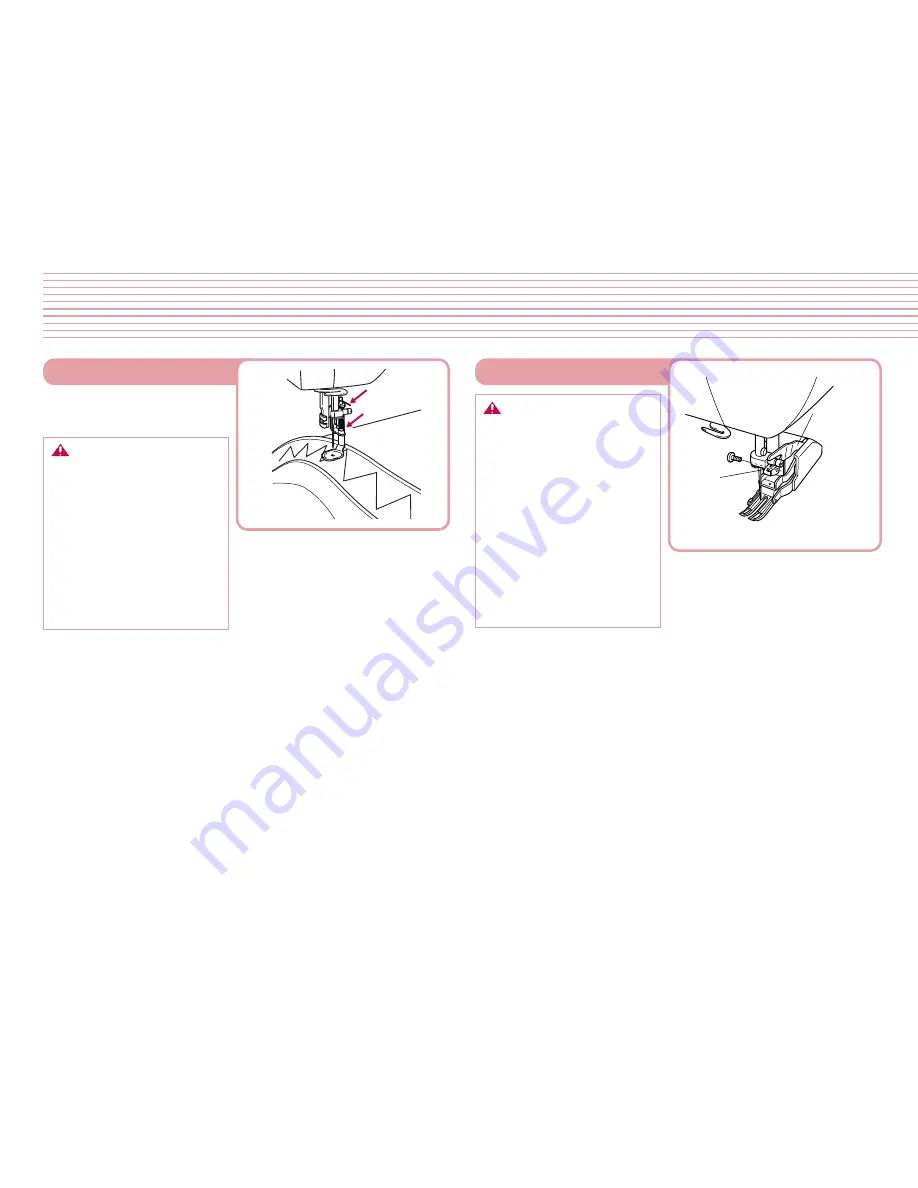

Quilting Foot

Reduce the foot pressure and turn

the dial on the machine lowering the

feed dogs for free motion quilting.

Walking Foot

Forked part

of operation

lever

Secure the

capscrew

with a

screwdriver.

1

2

1

Insert the forked part of the op-

eration lever while raised in an

upright position onto the screw

on the right side of the needle

bar, as shown and then insert the

capscrew.

2

Tighten the screw securely with a

screwdriver. Tightening ad-

equately is important as the

screw might loosen due to the

foot and forked operation lever

vibration.

Note

•

Do not press the foot controller

all the way down.

Try to keep the sewing speed low

(500 r.p.m. or less).

•

The fabric may not feed if you

sew at high speeds.

•

The feed dog for feeding the

cloth may not move if the foot

pressure on the fabric is too

strong. Use the presser foot

pressure adjustment dial to

achieve the desired results.

•

It is not advisable or necessary

to use the Pin Feed mode with

the walking foot.

Note

•

If the foot is frequently used, be

sure to apply a small amount of

oil about once a month to the

area indicated by the arrow. (If

too much oil is applied, wipe off

the excess with a cloth.)

•

For best results when using me-

tallic or monofilament threads

for free-motion quilting, sew with

a good quality thread, set upper

tension 1-2, and use a metallic

needle.

Summary of Contents for Jane BL500A

Page 1: ......

Page 2: ......

Page 51: ......

Page 52: ...ENGLISH FRENCH 884 639 XE8881 001 Printed in Taiwan...