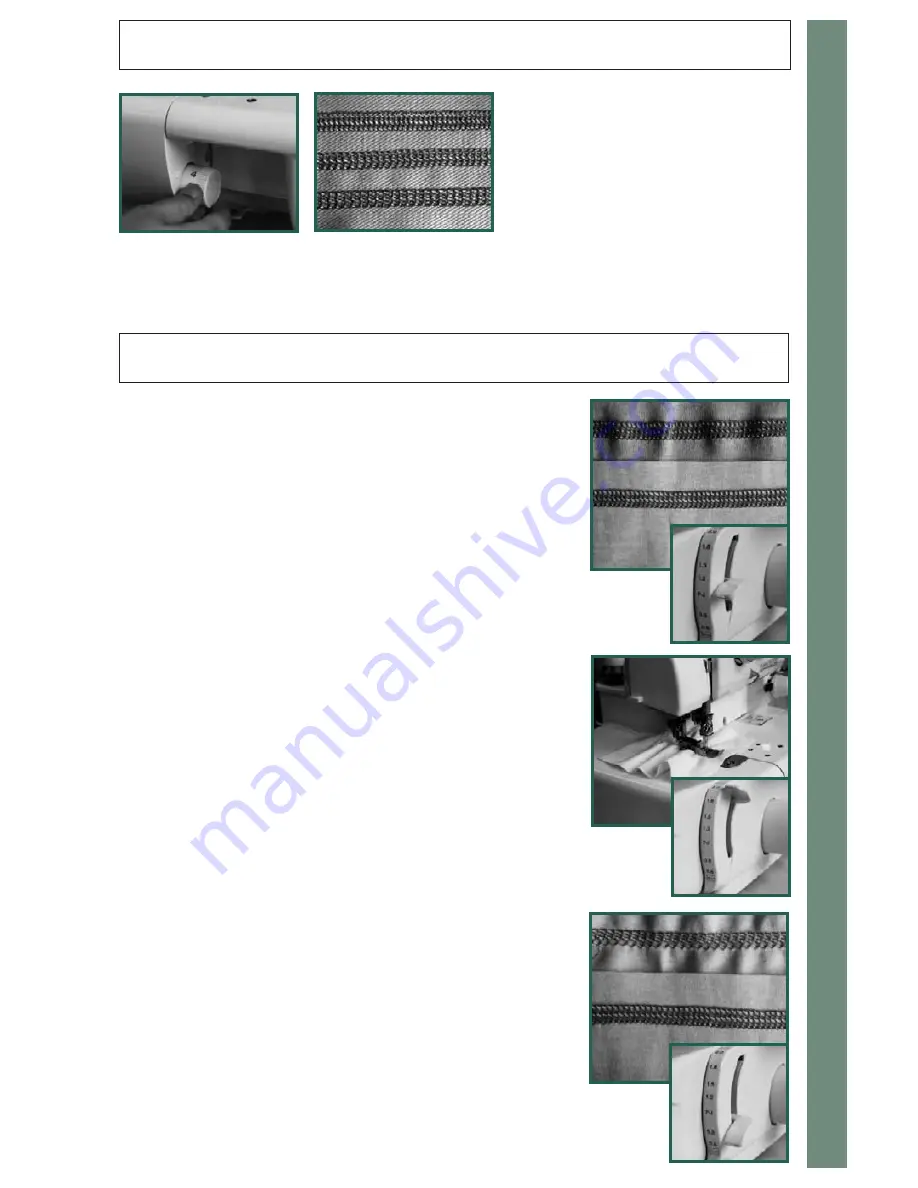

The stitch length adjusting dial is con-

veniently located just to the left of the

front cover, near the base plate (fig. A).

The dial shows the stitch-length rang-

ing from 1, for the shortest stitch, to 4

for the longest.

Simply turn the dial aligning the

desired setting with the indicator mark

on the machine. A stitch length of 3mm, or about 10 stitches per inch is ideal for most fabrics.

For seaming very lightweight fabrics, you may prefer a shorter stitch length. When sewing heav-

ier fabrics, you may choose to lengthen the stitch (fig. B).

O

V

E

R

V

I

E

W

11

Stitch Length

A

B

Differential Feed

Your Baby Lock serger is equipped with differential feed.The set of

feed dogs work independently in order to ensure smooth sewing on

all fabrics (fig. A)

When the differential feed adjusting lever, located at the machine's

right, front edge is set on "N" for normal feeding, the feed dogs move

the same distance. This is the setting to use for most fabrics and

applications (fig. B).

When the dial is set above "N", the front feed dog will feed more fab-

rics than the back. This is because the front feed dog moves at a

greater distance than the back feed dogs. As a result, the fabric

becomes compressed or eased, as the diagram on the front cover

indicates. This can eliminate wavy seams in stretchy fabrics or those

cut on the bias grain.

At the maximum setting of 2.0 (fig. C), the differential feed can gath-

er a lightweight fabric to nearly double fullness (fig. D).

The front feed dog is actually feeding in twice as much fabric as the

back feed dog is feeding out. To maximize the gathering effects, use

the longest stitch length setting. Fabric weight will affect the gather-

ing. Test stitch for desired results.

When the differential feed lever is set below "N" (fig. F), the front feed

dog moves less distance than the back feed dog. This adjustment

stretches the fabric slightly as it is sewn. The lower settings prevent

puckers on lightweight fabric (fig. E).

A

B

D

E

F

C