a

fig. 12

a

fig. 13

a

- 12 -

11. ZIGZAG TIMING • NEEDLE

STOP POSITION

The zigzag timing and the needle stop position when

start/stop switch is pressed are controlled by the

computer system. However, the needle bar position

(upper shaft revolution angle) is detected by the sensor

slit.

Therefore, if the slit is not correct position, the timing and

stop position will be incorrect. Adjust as follows:

1. Remove the front cover.

2. Loosen the screw (a) on the timing slit with a hexagon

socket screw key (1.5 mm). (fig. 11)

Align the guide-lines on the upper shaft and left side of

slit.

At this adjustment, do not move the slit side-ways.

3. Tighten the screw (a).

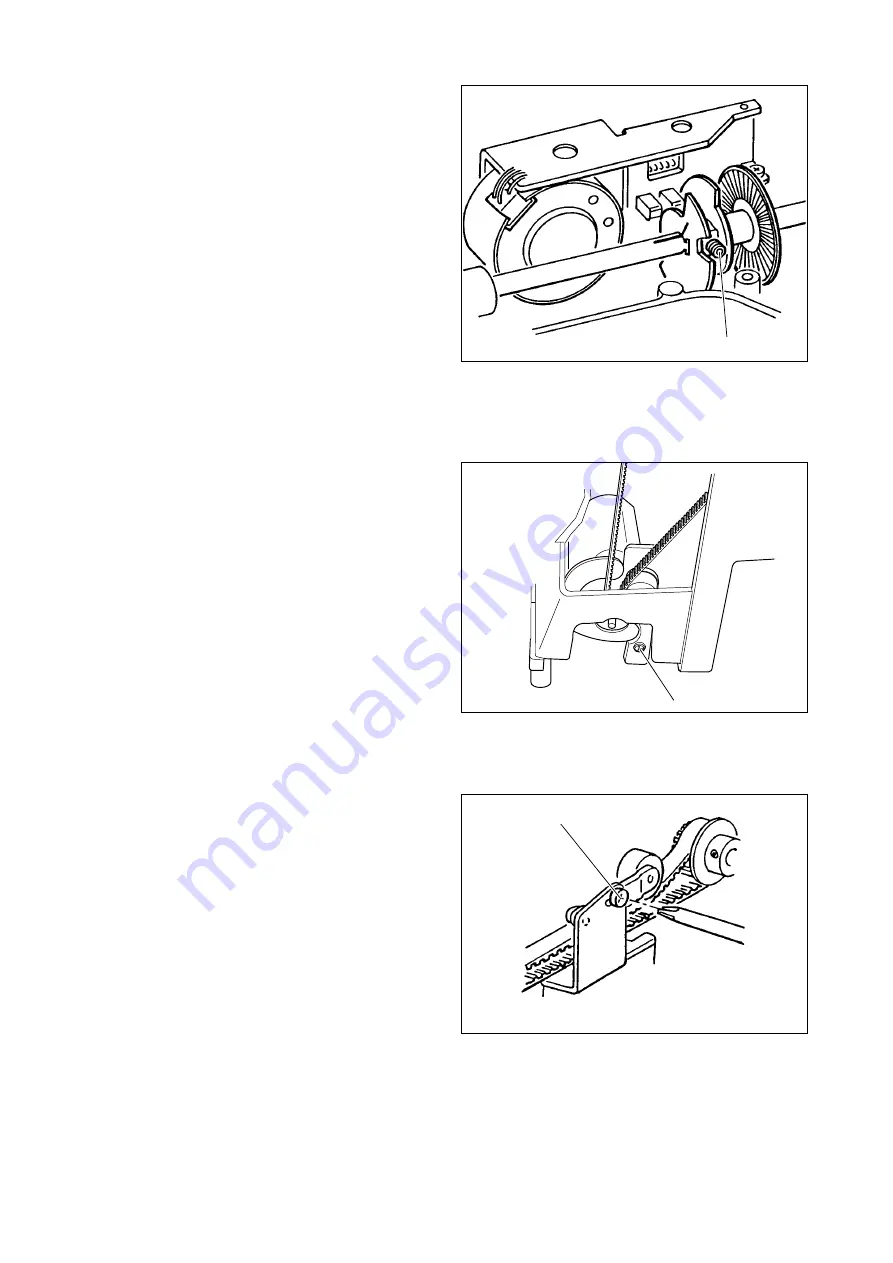

12. MOTOR BELT TENSION

If the motor belt tension is too tight or too loose, machine

will not run smoothly.

Adjust as follows:

1. Remove the front cover.

2. Loosen the screw (a). (fig. 12)

3. Push the pulley towards the belt so that the belt should

have flexibility of 5-6 mm when average pressure is

applied on its side.

4. Tighten the screw (a).

13. TIMING BELT TENSION

If the timing belt is too tight or too loose, the machine will

run heavily or the timing of hook and feed motion will be

changed incorrectly.

Adjust as follows:

1. Remove the front cover.

2. Loosen the screw (a). (fig. 13)

3. Push the pulley towards the belt and tighten screw.

The belt tension should have a flexibility of 4-5 mm

when average pressure is applied to its side.

When you have adjusted the timing belt tension, recheck

the timing of the feed motion (sec. 6) and the timing of the

hook (sec. 3 ) again.

fig. 11 View from lowerside