NAMES OF MACHINE PARTS AND THEIR FUNCTIONS

B-17

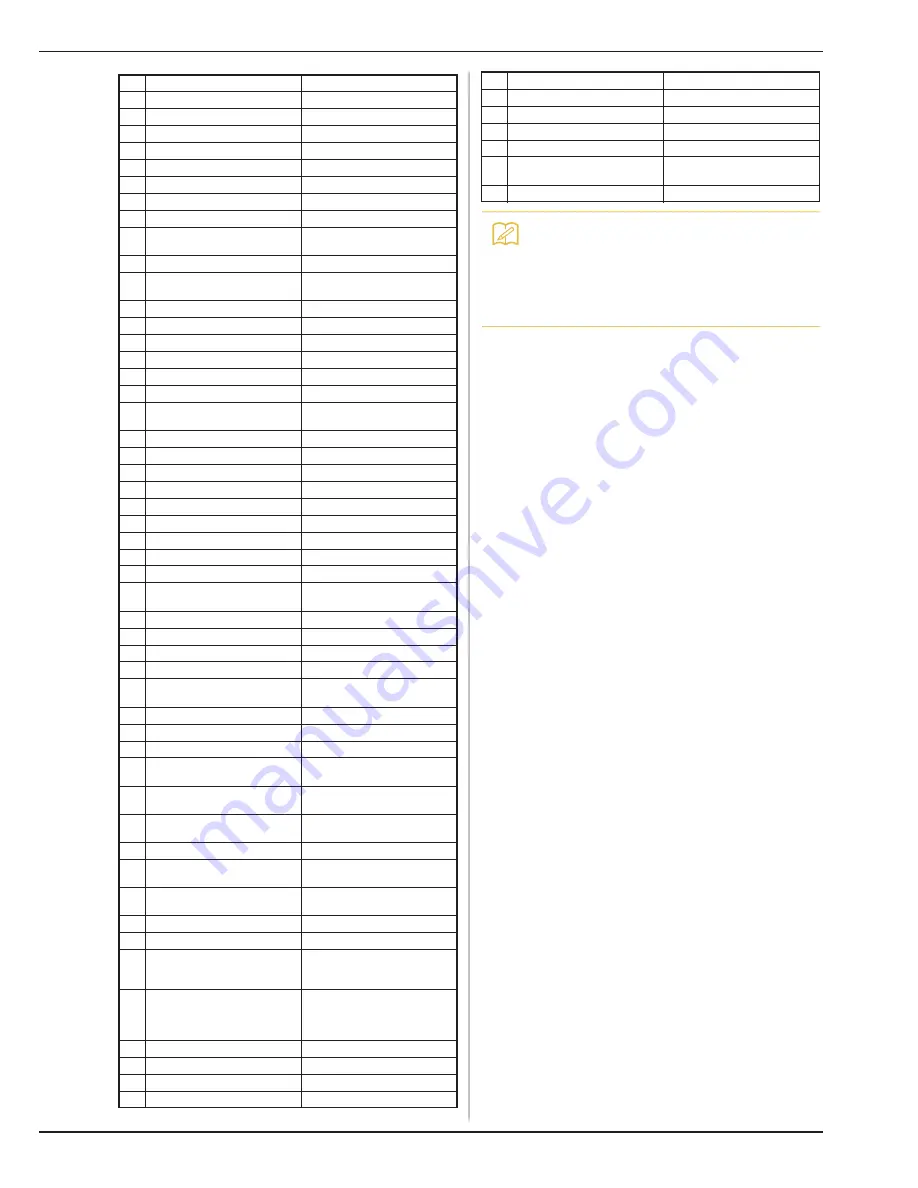

No.

Part Name

Part Code

1

Zigzag foot “J” (on machine)

XF3022-001

2

Monogramming foot “N”

X53840-351

3

Overcasting foot “G”

XC3098-051

4

Zipper foot “I”

X59370-051

5

Buttonhole foot “A”

X57789-251

6

Blind stitch foot “R”

X56409-051

7

Button fitting foot “M”

130489-001

8

Straight stitch foot

XD0826-051

9

Embroidery foot “W+” with

LED pointer

XF3124-001

10 1/4” quilting foot with guide

XC6800-251

11 Free motion open toe quilting

foot “O”

XF4873-001

12 Dual feed foot

XF4068-001

13 Adapter

XF3613-001

14 Screw (small)

XA4813-051

15 Needle set

X58358-051

16 Twin needle

X59296-151

17 Ball point needle set

XD0705-051

18 Bobbin × 10

(One is on machine.)

X52800-150

19 Seam ripper

XF4967-001

20 Scissors

XC1807-121

21 Cleaning brush

X59476-051

22 Eyelet punch

XZ5051-001

23 Screwdriver (small)

X55468-051

24 Screwdriver (large)

XC4237-021

25 Disc-shaped screwdriver

XC1074-051

26 Vertical spool pin

XC8619-052

27 Spool cap (small)

130013-154

28 Spool cap (medium) × 2

(One is on machine.)

X55260-153

29 Spool cap (large)

130012-054

30 Spool cap (mini insert)

XA5752-121

31 Spool felt (on machine)

X57045-051

32 Spool net × 2

XA5523-050

33 Embroidery needle plate

cover

XE5131-001

34 Touch pen (stylus)

XA9940-051

35 Knee lifter

XA6941-052

36 USB cable

XD0745-051

37 Alternate bobbin case

(no color on the screw)

XC8167-551

38 Bobbin center pin and

instruction sheet

XC8661-251

39 Bobbin case (gray, for bobbin

work)

XE8298-001

40 Straight stitch needle plate

XF3076-001

41 Cord guide bobbin cover

(with single hole)

XE8991-101

42 Bobbin cover (with mark) (on

machine)

XF0750-101

43 Bobbin cover

XE8992-101

44 Foot controller

XC8816-051

45 Embroidery frame set (large)

H 180 mm × W 130 mm

(H 7 inches × W 5 inches)

EF75: Frame

EF79: Embroidery sheet

46 Embroidery frame set

(extra large)

H 300 mm × W 180 mm

(H 12 inches × W 7 inches)

EF76: Frame

EF80: Embroidery sheet

47 Embroidery bobbin thread

BBT-W

48 Stabilizer material

X81176-001

49 Power cord

XC6052-051

50 Chalk pencil

XE8568-001

51 Sensor pen holder

XF4702-001

52 Pen holder

XF2973-001

53 Dust cover

XF4694-001

54 Accessory bag

XC4487-021

55 Instruction and Reference

Guide

XF3648-001

56 Quick Reference Guide

XF3649-001

Memo

• Foot controller: Model T

This foot controller can be used on the

machine model: BLTY.

• Always use accessories recommended for

this machine.

No.

Part Name

Part Code

Summary of Contents for Urity BLTY

Page 1: ......

Page 109: ...USEFUL FUNCTIONS Sewing Basics Sewing S 19 S 1...

Page 193: ...USING THE MEMORY FUNCTION Character Decorative Stitches Sewing S 103 S 3...

Page 206: ...TROUBLESHOOTING S 116...

Page 224: ...ATTACHING THE EMBROIDERY FRAME E 18 b Pull the embroidery frame toward you...

Page 304: ...TROUBLESHOOTING E 98...

Page 331: ......

Page 332: ...English 882 C41 Printed in Taiwan XF3648 001...