BAC Document Number: Easybond MKII Manual V03

28/08/13

Page

18

of

32

8.

FAULT DIAGNOSIS OF UNSATISFACTORY PIN BRAZE CONNECTION

Some common problems can be experienced by operators when first using the equipment.

Listed below are a series of faults together with the most likely cause and remedy solutions. In

the event of persistent problems or faults, contact the service engineer for advice or repair.

PROBLEM

POSSIBLE CAUSE

REMEDY

No arc or there is a short

“pop” of the pin

Circuit not complete or

highly resistive

Check fuse wire on pin is

engaged

Check earth device is connected

Batteries flat

Charge/replace batteries

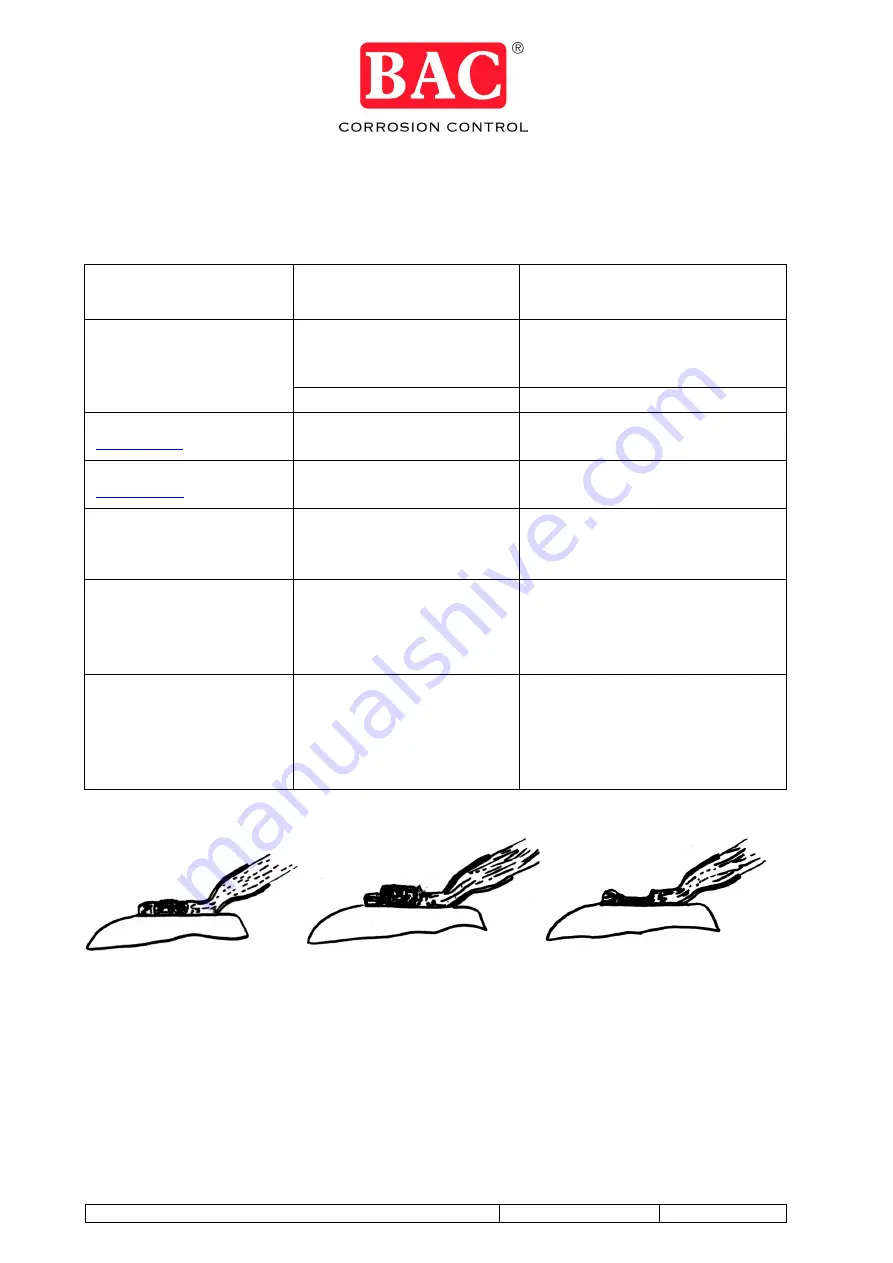

Arc time too short

Figure 9 (B)

Excessive current drawn

Poor earth connection

Check gun adjustment

Reset earth connection

Arc time too long

Figure 9 (C)

Insufficient current drawn

Check gun adjustment

Recharge batteries

Bond falls

off

when

tested

Too short brazing time

Base

metal

not

clean

enough

See above

Thoroughly clean the area to be

brazed

Fuse

wire

stuck

in

contact nipple

Pin loose in holder

Failure to eject previous

fuse wire

Tighten fit of pin holder jaws

Replace contact nipple

Brazing pin fails to push

into

molten

braze

material

Pin is out of line from the

ferrule due to off centre

ferrule

holder

jaws

caused by heavy removal

of spent ferrule

Take care not to bend ferrule

holder jaws when removing

spent ferrule

Replace ferrule holder

A.

B.

C.

Figure 9