10

FXV, FXV3, CXVB, AND CXVT UNITS

Detailed Component

Maintenance Procedures

2

Cold Water Basin

The fluid (refrigerant) to be cooled (condensed) is circulated inside the tubes of the unit’s

heat exchanger. Heat flows from the process fluid through the coil to the spray water

outside which is cascading over the tubes. The spray water collects in the cold water

basin, passes through the suction strainer and is pumped back to the distribution system.

The cold water basin is constructed from one of the following materials of construction.

• Galvanized steel

• TriArmor

®

Corrosion Protection System

• Welded Type 304 stainless steel

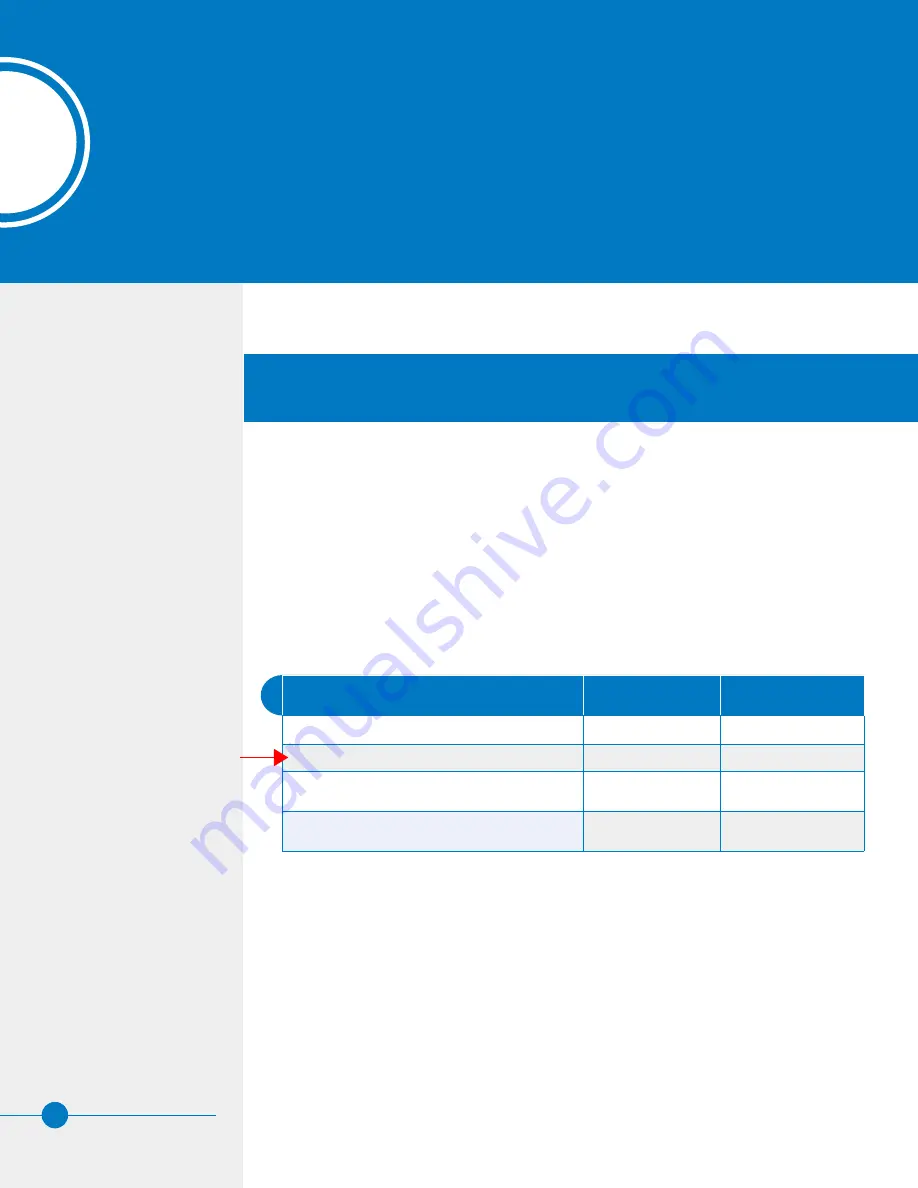

Water Levels

Model Number

At Overflow Level (in.)

At Operating Level (in.)

FXV-08xx, CXVB-xxx-08xx

13 1/2”

8 1/4”

FXV-12xx, CXVB-xxx-12xx

14 1/2”

8”

FXV3-1224-xxx, FXV3-1426-xxx, CXVT-x-1224-x,

XECXVTx-1224-x,CXVT-x-2424-x, XECXVTx-2424-x

19 1/4"

16 1/4"

FXV3-1224-xxx, FXV3-1426-xxx, XECXVTx-1426-x,

CXVT-x-2826-x, XECXVTx-2826-x

19 1/4"

16 1/4"

• The operating water level in the cold water basin will vary with system thermal load

(evaporation rate), the bleed rate employed, and the make-up water supply pressure.

• The make-up valve controls the operating level, which is maintained at the levels

shown in

Table 1

.

• Check the operating water level monthly, and readjust the float when necessary to

maintain the recommended operating level.

• Consult “Water Level Control” on

for information on how to set and maintain

basin operating level.

Table 1.

Cold Water Basin Water Levels (Measured from Inside the Cold Water Basin)