15

15

Detailed Component

Maintenance

Procedures

Fan Drive System

BALTIDRIVE

®

Power Train and

Independent Fan

•

Belt tension check:

– Place a straight edge along the belt from sheave to sheave as shown in

Figure 5a

, or

use a tape measure as shown in

Figure 5b

, to measure belt deflection.

– Apply a moderate force by hand (approximately 40 lbs/275 kPa) evenly across the

width of the belt in the center of the span between the sheaves.

– There is adequate belt tension if the belt deflects between 1/4” and 3/8” as shown

in

Figures 5a

and

5b

.

•

Belt tension adjustment (if required):

– Loosen the lock nut on the motor base adjusting screw.

– Turn the motor base adjusting screw counterclockwise to tension the belt, or

clockwise to relieve belt tension. During adjustment of belt tension, rotate the drives

several times by hand to evenly distribute the tension throughout the belt.

– When the belt is properly tensioned, retighten the locking nut on the motor base

adjusting screw.

•

Drive alignment check and adjustment:

– Check the drive alignment annually to ensure maximum belt life.

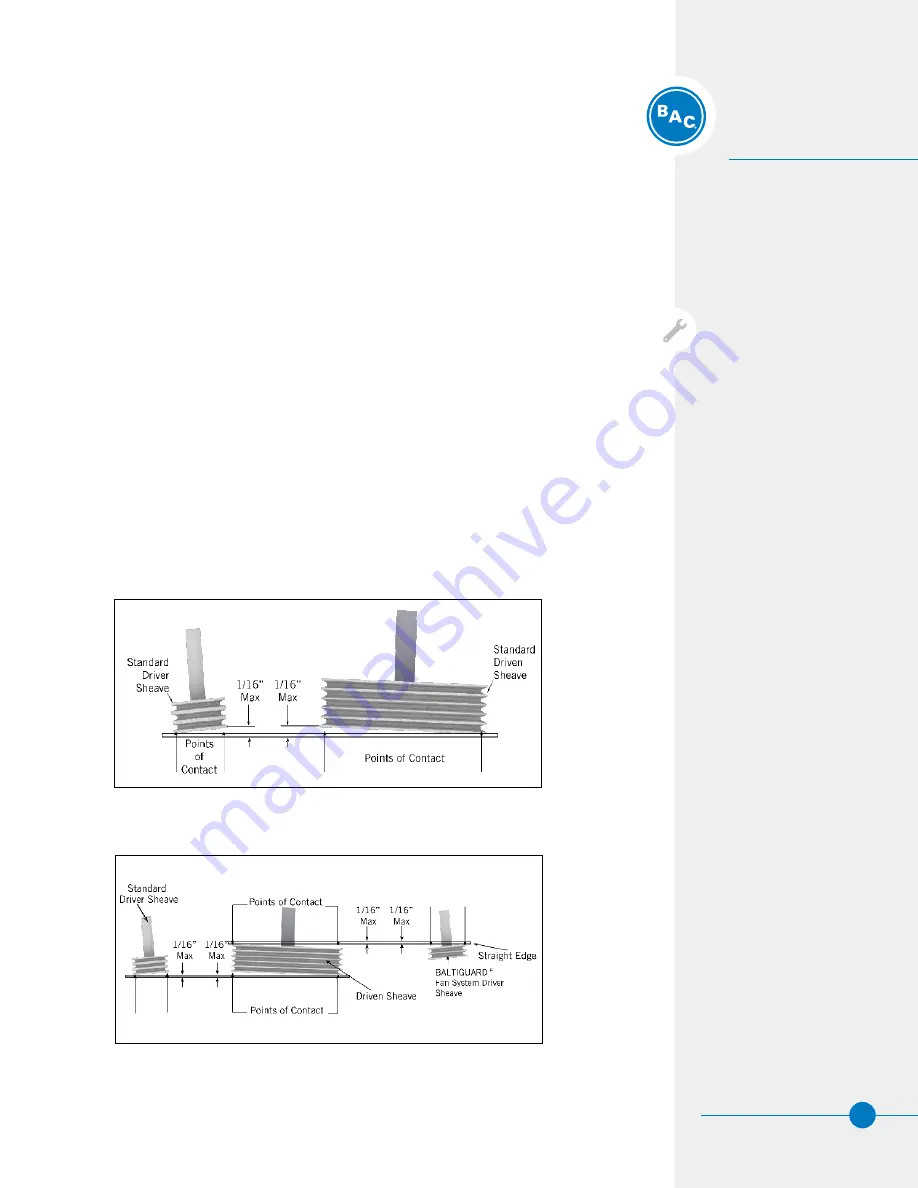

– Place a straight edge across the driver and the driven sheaves as shown in Figure 6a

NOTICE:

Ensure the controls for

the fan and pump motors are set

to allow a maximum of six on-off

cycles per hour to prevent motor

overheating.

Figure 6a.

Standard Drive Alignment

for standard drives and in

Figure 6b for the BALTIGUARD™ Fan System.

– There should be no more than 1/16” deviation from four points of contact.

– If realignment is required, loosen the motor sheave and align it with the fan sheave.

Allow 1/4” for draw-up as the bushing screws are retightened.

Figure 6b.

BALTIGUARD™ Fan System Drive Alignment