6

Operating Modes

•

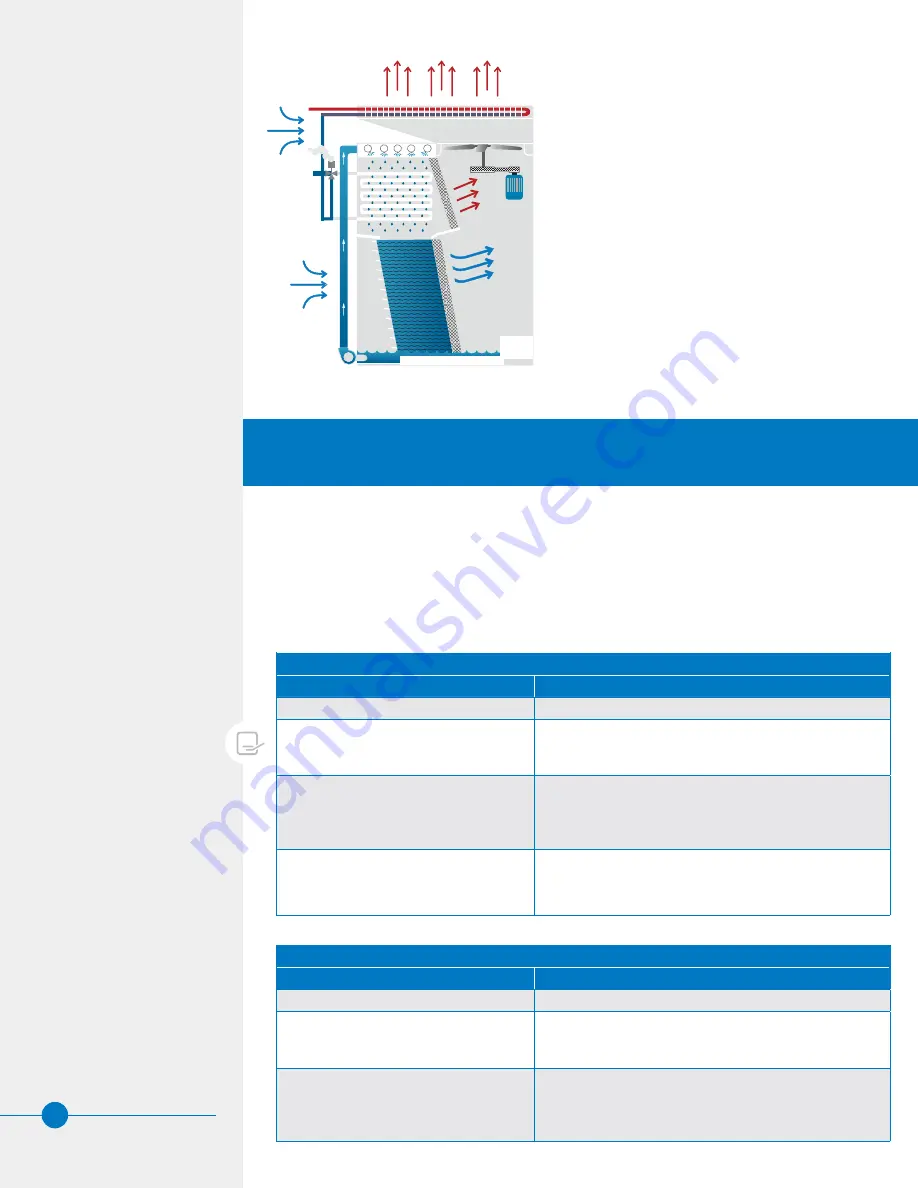

Adiabatic Mode (Balanced Water and

Energy Savings):

The spray water

circulating pump distributes water

over the fill surface. The fans draw

air over the wetted fill where it is

adiabatically pre-cooled resulting is a

significantly lower air temperature and

greatly increasing the rate of sensible

heat transfer. The process fluid is

only circulated through the dry finned

coil. To enable this mode, a customer-

supplied three-way valve is needed.

Table 1.

Sequence of Operation

Sequence of Operation with a 3-way Valve

Conditions

Operation

No Heat Load

Spray pump OFF; Fans OFF

Peak (design) operating conditions -

Ambient wet bulb ≥ Design wet bulb

Energy Saver Mode:

Spray pump ON; Fan motors ON with VFD - fan

motors ramp up and down together. 3-way valve fully closed to allow

full flow through evaporative coil.

Fan speed is reduced based on load and reaches

customer-defined fan speed switchpoint

OR

Ambient dry bulb ≤ Design adiabatic operation

switchpoint temp

Adiabatic Mode:

Spray pump ON; Fan motors ON with VFD - fan

motors ramp up and down together. 3-way valve opens to bypass

evaporative coil, thereby saving water.

Fan speed is reduced based on load and reaches

customer-defined fan speed switchpoint

OR

Water Saver Mode:

Spray pump OFF; Fan motors ON with VFD - fan

motors ramp up and down together. 3-way valve fully closed to allow

full flow through evaporative coil to maximize dry performance.

NOTE:

LWT= Fluid Cooler Leaving

Water Temperature

Sequence of Operation

The following is applicable to all sequences of operation:

• All fan speed control operation is based on leaving fluid temperatures.

• Basin heaters are interlocked with the spray pump, and only operate when the spray

pump is off and the basin temperature is less than 40°F.

• For extra coil freeze protection, spray pump can be locked out if ambient temperature

is less than 32°F

Figure 2c:

Adiabatic Mode

Sequence of Operation without a 3-way Valve

Conditions

Operation

No Heat Load

Spray pump OFF; Fans OFF

Peak (design) operating conditions - Process

fluid leaving temperature ≥ Customer setpoint

Energy Saver Mode:

Spray pump ON; Fan motors ON with VFD - fan

motors ramp up and down together. Process fluid flows through dry

coil and evaporative coil in series.

Fan speed is reduced based on load and reaches

customer-defined fan speed switchpoint

OR

Ambient dry bulb ≤ Design dry operation switch-

point temp

Water Saver Mode:

Spray pump OFF; Fan motors ON with VFD - fan

motors ramp up and down together. Process fluid flows through dry

coil and evaporative coil in series to maximize dry performance.

Table 1a:

Sequence of Operation with a 3-way Valve

Table 1b:

Sequence of Operation without a 3-way Valve