WWW.BALTIMOREAIRCOIL.COM

12

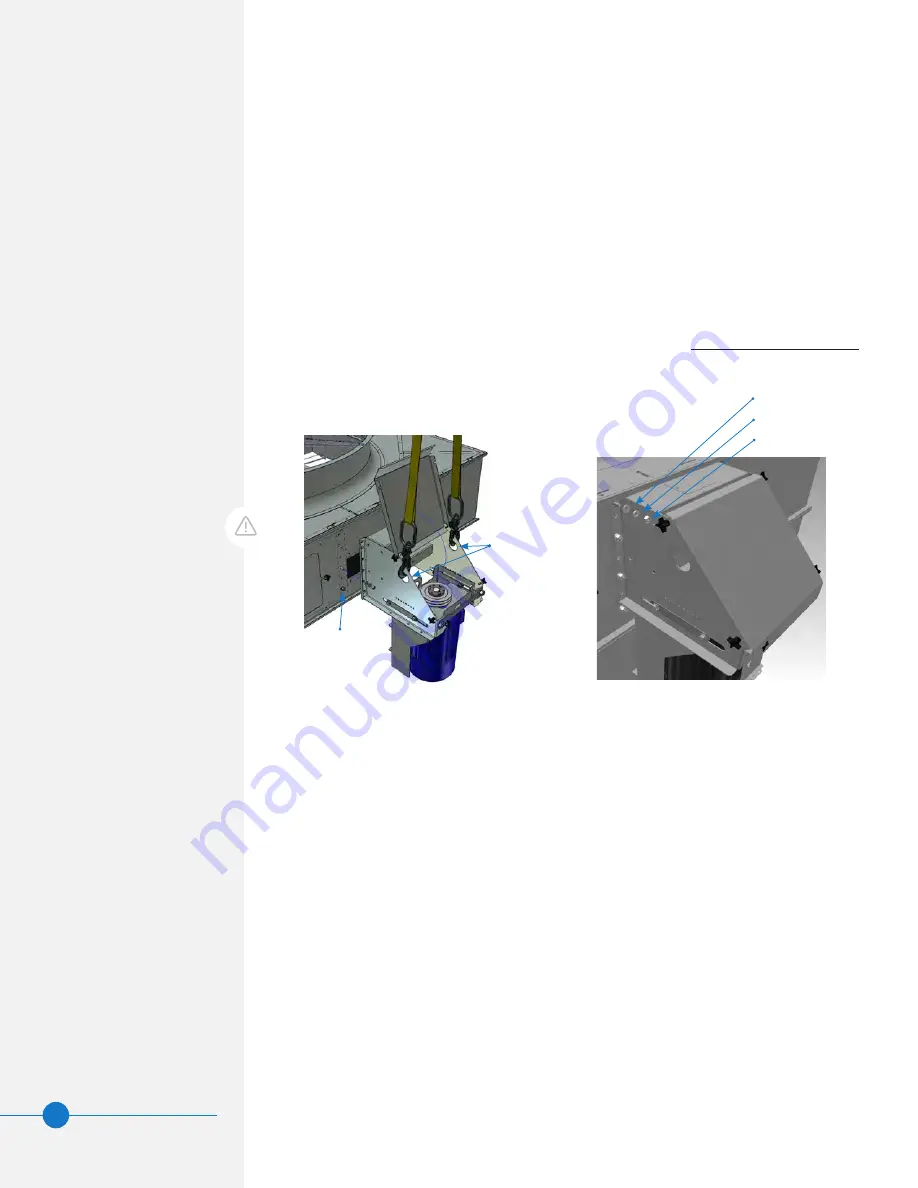

Figure 17.

External Motor Mount Assembly Lift

1/2” washer

1/2” lock washer

1/2” nut

Eyelets

Motor Installation for External Motors

Models with external motors include PFi/PCC-0709, PFi/PCC-0718. All other PFi and PCC

models have the fan motor mounted and belt tensioned at the factory.

1. Attach the lifting strap to the motor base eyelets and remove the motor and the motor

base assembly from the basin. The motor assembly must remain vertical to maintain

proper alignment during installation.

2. Lift the external motor assembly into position next to the access door.

3. Attach the assembly to the unit using the six ½” studs, flatwashers, lock washers, and

nuts.

4. Install the power band, check sheave alignment, and tension the power band. For

correct sheave alignment and tensioning specifications and procedures, refer to the

PFi and PCC Operation & Maintenance Manual

available at www.BaltimoreAircoil.com.

Tapper

DO NOT

REMOVE

Figure 18.

External Motor Mount Assembly Pattern

CAUTION:

Do not remove tappers

from the fan section during the

installation of the external motor.

Removing tappers will cause the

interior mechanical system to fall.