WWW.BALTIMOREAIRCOIL.COM

5

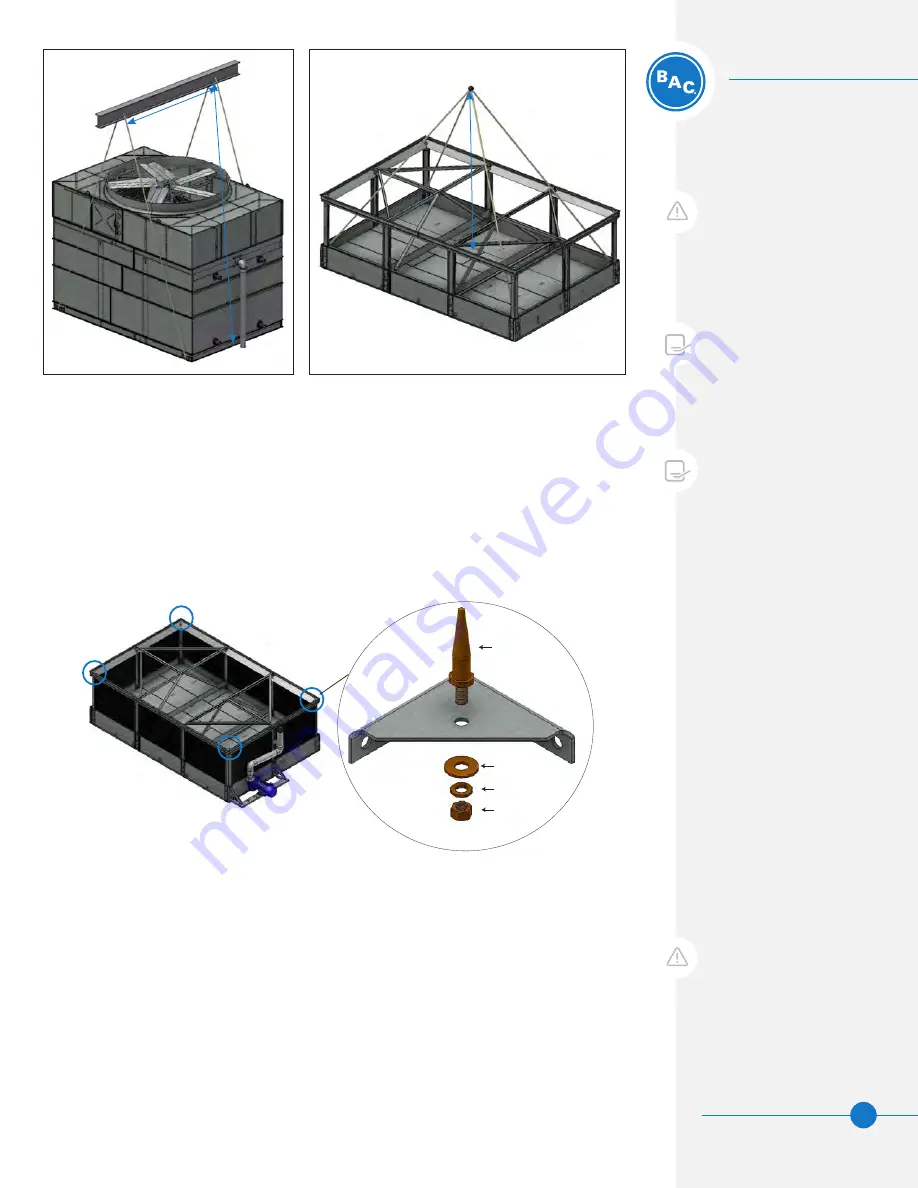

Section Assembly of Two-Piece Cells

1.

Figures 2 and 3

show the proper rigging of sections for units that ship in two pieces.

2. Remove any motors or accessories shipped in the lower section.

3. For units that ship with rigging alignment pins, install the pins on the cold water basin

in the locations shown in

Figure 4

. Secure the alignment pins using the 1/2” hardware

provided from the factory.

NOTE:

All pump piping must be

restrained to ensure no vertical or

horizontal movement. All piping

and supports are to be furnished

by others. Refer to the submittal

drawing for details on piping

connection sizes, etc.

PF

i

AND PCC

Unit Rigging & Assembly

Unit Rigging & Assembly

Rigging

Section Assembly of

Two-Piece Cells

NOTE:

The IBC Rating is void if the

section assembly is not performed

as described in this manual.

Figure 2.

Upper Section Two-Piece Lift

(Casing and Mechanical)

Figure 3.

Lower Section Two-Piece Lift

H

H

W

WARNING:

Do not lift the

mechanical (top) section attached

to the coil casing section from the

mechanical section lifting ears. Lift

both sections from the coil casing

lifting ears.

CAUTION:

Any motors or

accessories shipped in the cold

water basin must be removed prior

to installing the upper (mechanical

and coil casing) section.

Figure 4.

Alignment Pin Locations

1/2” Flatwasher

Alignment

Pin

1/2” Lockwasher

1/2” Nut

Detail A

4. Position the lower section on the steel support and bolt in place.

5. Wipe any moisture or dirt from the top perimeter flange of the lower section.

6. Install flat butyl sealer tape (BAC part # 554000) supplied with the unit, on the

mating flanges of the lower section in a continuous line. At each corner, allow 1”

overlap.

7. Lower the hose connection on the pump discharge piping below the elevation of the

lower section before rigging the coil casing section.

8. Lower the upper section (coil casing and mechanical) until it is hovering 2-6” above

the lower section.