Operation

Fyrite

InTech

Manual

42

0024-9486 Rev 4

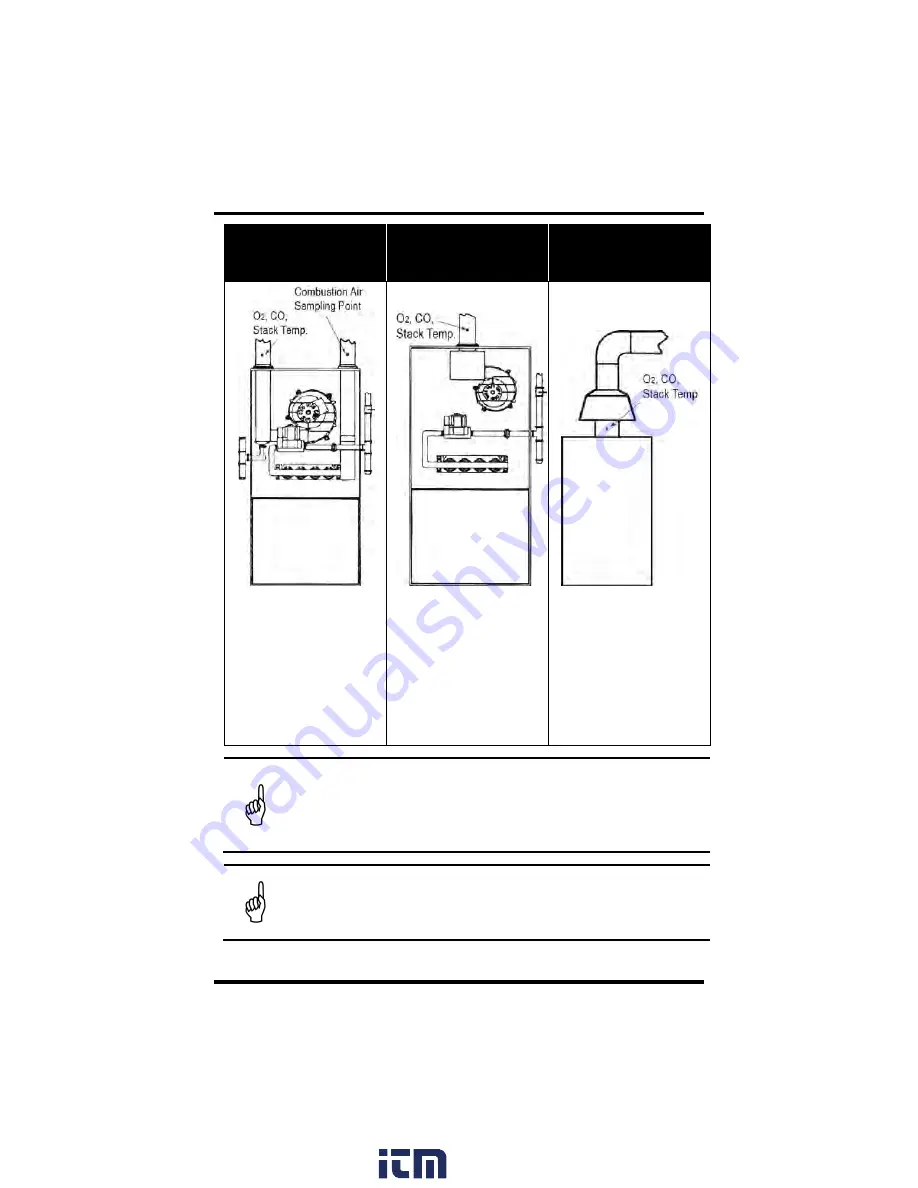

Example 90% Efficiency

Condensing Furnace

Example 80% Efficiency

Fan Assist or Power

Vented Furnace

Example

Atmospheric/Gravity

Vented Boiler

Condensing

furnaces/

boilers can be tested

through a hole drilled in

the plastic vent pipe

(when allowed by the

manufacturer

or local

authority of jurisdiction)

or taken from the exhaust

termination.

Combustion testing of fan

assist or power vented,

furnaces/boilers should be

done through a hole

drilled

in

the

vent

immediately above the

inducer fan.

Boilers, which have a ‘bell’

shaped draft diverter on

top, should be tested

directly below the diverter

through a hole drilled in

the vent connector.

IMPORTANT: Review manufacturer recommendations for the

combustion device being tested, and be aware of accepted

practices of the local jurisdiction before introducing sampling holes

into exhaust pipes or ducts.

CAUTION: To avoid the introduction of dangerous exhaust gases

into the space, be sure to completely and securely seal any sampling

holes made in the exhaust pipes or ducts.

www.

.com

information@itm.com

1.800.561.8187