MGS-250 Manual

6490-9000 Revision 4

15

1.3. Remote Controller Options

The MGS can connect to any controller through the standard analog

output (voltage and current; see Table 4 for options), the standard alarm

relay, or the digital Modbus RTU communications interface.

1.4. Parts List

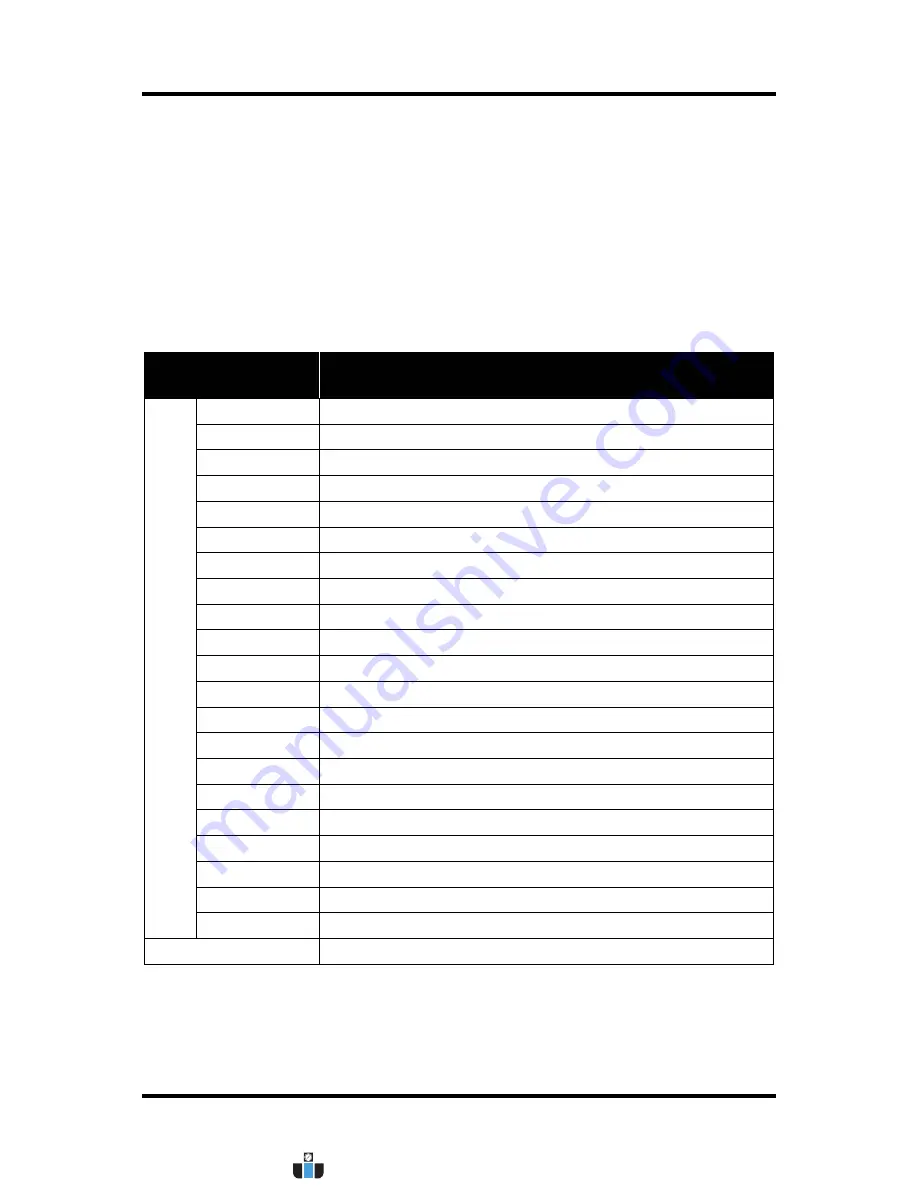

Table 3 shows a list of components that are shipped with your order.

Table 3: Parts List

Part Number

Description

Variou

s (D

ep

end

s on

Mo

del O

rdered)

6401-0500 MGS-250,

Broadband

6401-0501 MGS-250,

R22

6401-0502 MGS-250,

R123

6401-0503 MGS-250,

R134a

6401-0504 MGS-250,

R404a

6401-0505 MGS-250,

R407a

6401-0506 MGS-250,

R407c

6401-0507 MGS-250,

R407f

6401-0508 MGS-250,

R410a

6401-0509 MGS-250,

R422a

6401-0510 MGS-250,

R422d

6401-0511 MGS-250,

R427a

6401-0512 MGS-250,

R507

6401-0513 MGS-250,

HFO1234YF

6401-0514 MGS-250,

HFO1234ZE

6401-0515 MGS-250,

HFO1233ZD

6401-0516 MGS-250,

R32

6401-0517 MGS-250,

R448A

6401-0518 MGS-250,

R449A

6401-0519 MGS-250,

R513A

6401-0520 MGS-250,

R452A

6490-9000

Installation and Operation Manual

www.calcert.com

sales@calcert.com

1.888.610.7664

0

5

10

15

20

25

30