HGM-MZ Refrigerant Monitor

Quick Start Installation Instructions

Revision

2

- 3 -

P/N: 3015-9003

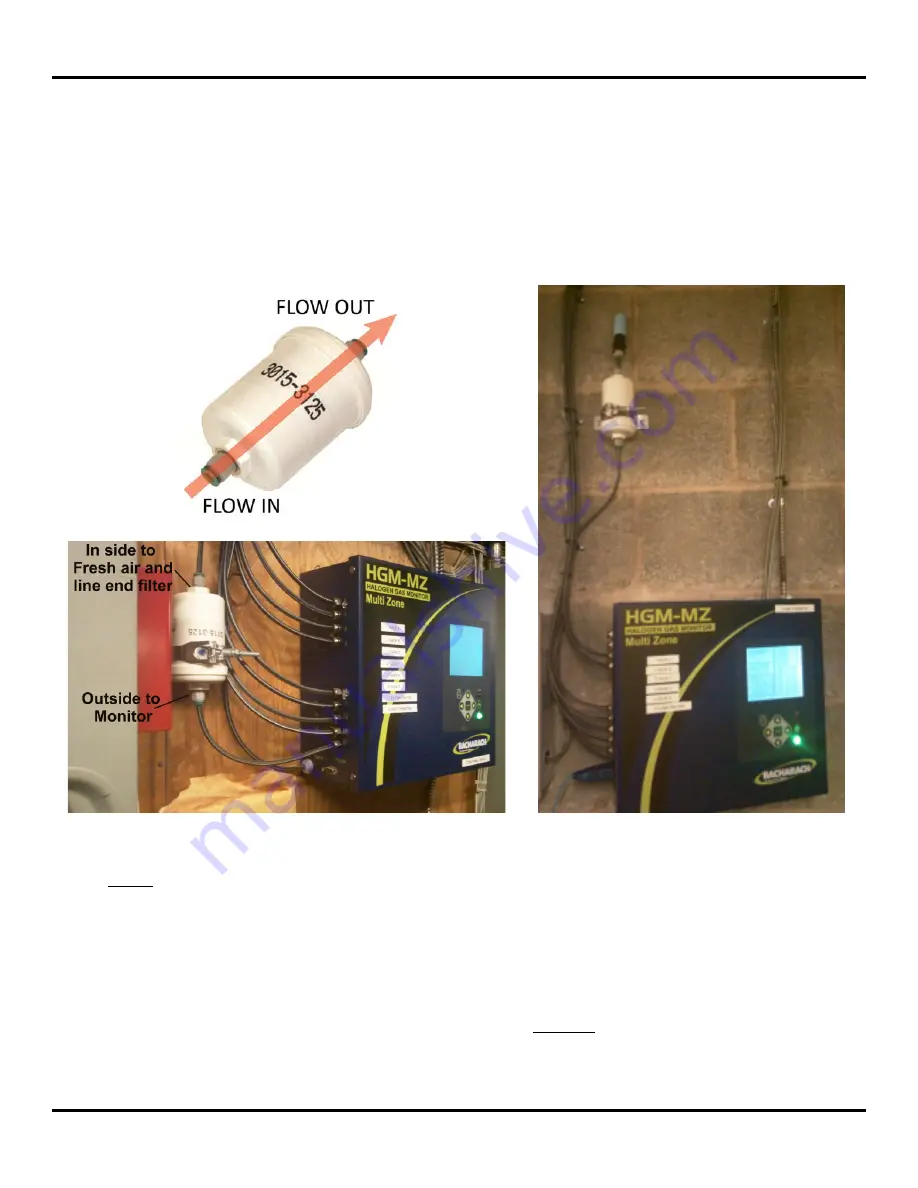

11. CONNECT FILTER’S “FLOW IN” SIDE: Run tubing from the “IN side” of the charcoal filter to a location that is

outside of the structure (machinery room). Locate it in an area where the line end filter (a) can be easily

accessed for replacement, and (b) where it will remain dry and free from direct rain or excessive moisture.

This is the optimum installation scenario. See Figure 6.

If this cannot be accomplished, the end of line filter can be mounted

inside

(near the monitor and charcoal

filter) in an accessible area to allow easy replacement. NOTE: In the case of indoor filter installation, the

monitor

must be put in service mode

when refrigerant is released (e.g., during maintenance) to prevent

premature purge filter contamination. See Figure 7.

Figure 6. Outdoor Filter Mounting Example (Optimum)

Figure 7. Indoor Filter Mounting Example

NOTE:

a. If you are mounting the purge pickup

outside

the structure, you must place the tubing in an area

away from the elements in a “secure area that is out of the reach of rain and snow” and is

accessible for filter changes.

b.

In the case of the CO

2

monitor

, you must mount the pickup

away from

CO

2

sources (i.e., gas-fired

appliance stacks, rack room, store ventilation, truck bays, etc.) which can skew the purge baseline.

c. If mounting a purge pick up

inside

the structure, you

must not

have prolonged background ambient

refrigerant contamination as this will cause the charcoal purge filter to fail prematurely (refer to

fault code 0100).