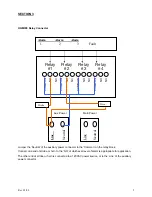

9. Connect the tubing from the reference Gas regulator to Zone 1on the manifold of HGM300.

NOTE:

Fault light on HGM300 may illuminate until gas starts to flow from the reference bottle.

Press the

enter key from keyboard the sensor readings will update indicated by a beep sound from the HGM300.

The pressure should be below the original readings, if not the unit is in a Purge cycle wait until purge

cycle is complete then continue. Adjust the variable regulator clockwise to set the pressure to the original

pressure reading from step 7 (press the enter key to update the readings).

NOTE: You may have to block

or partially block relief valve on variable pressure regulator in order to achieve desired pressure.

Continue this until pressure readings are the same as original readings. Allow the gas to flow for 1

minute, continue to press the enter key while observing the first PPM reading (6

th

line) from the sensor

data menu. This value will stabilize to (typically) -5PPM of final reading. IF a purge cycle

interrupts the process, the reading will go to 0PPM, but should return to approximately the bottle value

when flow returns to zone 1. The reading should be -10% of the value indicated on the reference

bottle.

9.

Close reference bottle by adjusting variable regulator counter clockwise until fully closed. Return

Zone 1 parameters (length, refrigerant, hold time) to desired operating values.

10.

If the reading in step 8 is not within +-10% of the PPM reference bottle please check the following:

-Verify the pressure from step 8

-Check that tubing is securely connected to the reference bottle and Zone 1 input port

-Verify proper gas is selected (step 5)

-Verify unit is in hold for zone 1

-Verify that ample time was given for to stabilize and reading was not taken during a purge cycle

If the unit still does not measure -10% of the reference gas PPM, please contact the factory.

Rev 3/2/09

19