Instruction 3015-4149

21

•

PRESSURE SENSOR

– Manifold pressure is outside normal operating range (or sensor has failed).

Check the

Diagnostic Screen

record ALL data. Call the factory with this information for further

instructions.

•

LOOP FAULT

– This would be displayed only if the dual 4-20 mAdc option was installed and one or

both current loops are open. Check the wiring to load/monitoring circuit on both 4-20 mA loops.

•

CONFIG FAULT

– There is an error in

HGM Setup Screen #2

– Number Zones Installed field, or in

RDM Setup Screen #1

– Number of HGMS on Network field. Check that the number of zones

installed for each HGM unit and the number of HGM units on the network are properly programmed.

Check to ensure that the manifold solenoid cable connector in each HGM unit is securely fastened to

its terminal connector. Check for an illegal parameter. If necessary, reset to the factory default

settings.

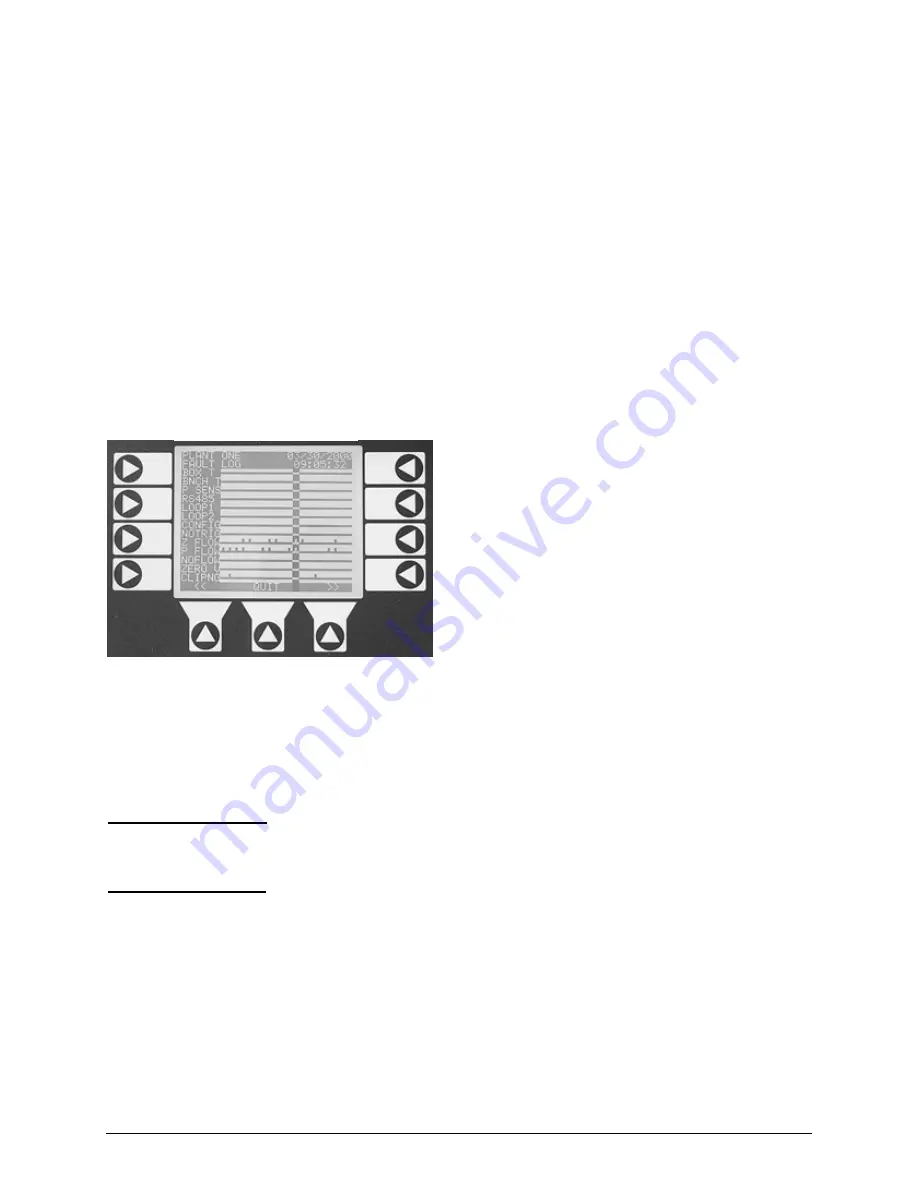

Viewing the Fault Log

From the Fault Screen press the button under LOG. This screen lists the last 20 fault conditions recorded

by the system. Using the left/right keys on the keypad you can move across the screen to view the time

and date of the fault.

Reset to Factory Default Settings

IMPORTANT:

Performing this function wipes out all program parameters, alarms, faults, trends and

log files.

Resetting the HGM300

– Press and hold down the Factory Default switch (left most switch inside the

HGM300); cycle AC power OFF then ON; listen for five beeps; and then release the switch. Reprogram

the HGM300 per Section 7 in this manual.

Resetting the RDM800

– Occasionally

it will be necessary to rest the RDM800 to its factory default

settings. From the System Screen, press and hold down the key adjacent to the ALARMS function; cycle

AC power OFF then ON; listen for five beeps; and then release the key.

Fault Log Screen