WARNING:

The MGS-550 MUST NOT

be in an alarm or fault

condition during calibration. Acknowledge any alarms or faults

BEFORE attempting to begin the calibration process.

WARNING:

Except for CO

2

or O

2

sensors, calibration gas must be

in a balance of air, not nitrogen (N

2

).

IMPORTANT:

Calibration and / or bump testing requires the

MGS-550 calibration adapter kit (P/N: 1100-0034).

1. Ensure the instrument has been powered on for at least 1

hour prior to beginning the sensor adjustment procedure.

For semiconductor sensors, you must wait at least 24 hours.

2. Assemble the calibration kit.

3. Firmly push the calibration adapter over the calibration

port on the sensor assembly.

4. If using a variable flow regulator, adjust the gas flow to

approximately 0.3 L/min.

6b. Zero Adjustment

WARNING:

Except for CO

2

or O

2

sensors, ambient air may be used

instead of zero gas if the area is know to be free of the target gas

or any gases to which the sensor may be cross-sensitive.

5. Enter the menu and select function F-02 Zero Sensor:

¾

Press the [UP]/[DOWN] arrows to select the sensor to be

calibrated, then press [

↵

].

6. Apply Synthetic air

(i.e., 20.9% zero air) or nitrogen,

and then

press [

↵

].

¾

T

he current value will be blinking in the display (e.g.,

“2”). The gas value may go negative. This is normal.

7. Wait for the current gas concentration value to stabilize.

8. Press [

↵]

to save the current calibration.

¾

The instrument will indicate success status with a

“PASS” display. If a “FAIL” message is displayed.

9. Turn off gas flow and remove the calibration adapter from

the sensor or disconnect the tubing.

¾

For oxygen, ensure that the concentration is below

the enrichment alarm thresholds.

Refer to user manual (P/N 1100-1000) for

troubleshooting.

10. Press [

↵

] to exit the function

11. Enter the menu and select function F-03 Zero Sensor:

¾

Press the [UP]/[DOWN] arrows to select the sensor

to be calibrated, then press [

↵

]. The last span gas

concentration will be displayed

12. Apply calibration gas at the concentration listed on the cal gas

concentration label

(located on top of the instrument)

:

• 50% Max Range for Butane, CO, CO2, Methane, NH3, NO2, O2, and Propane

(0-100% LEL) gas detectors

• Up to 100% (do not exceed 100%) Max Range for all other gas detectors

Calibration

Adapter

7. Bump Test

1

-Each of the three relays can be configured for low alarm, medium alarm, high alarm or fault – this example of operation assumes a low alarm, high alarm

and fault configuration

5. Operation Overview

Button / Mag Switch

Description

Hold:

3sec - Access User Menu

Hold:

3sec - Returns to next higher menu without saving changes (ESC)

Press / Tap:

Brings up sensor ID in succession

Press / Tap:

Scrolls through User Menu in sequence

Hold:

Accelerates scrolling

Hold Up Arrow at Top of Menu:

Enters Diagnostic Screen

Press / Tap:

Confirms menu selection

Press / Tap During Alarm:

Mutes buzzer

Hold:

Cancels Off-Line Mode

Hold:

Acknowledge latched alarm / fault

STATE

LEDs

Display

Relay 1

1

Relay 2

1

Relay 3

1

Buzzer

Warm-Up

Flashing Green, 0.5 Hz

Display is blank

Off-line

Off-line

Off-line

OFF

Normal

Constant Green

Toggles between target gas name and real-time

concentration for each sensor installed

Normal

Normal

Normal

OFF

Low Alarm

(Sensor 1 and / or

Sensor 2)

Flashing Red, 0.5 Hz

Display will toggle between ALARM, gas name,

concentration of each sensor until concentration falls below

low alarm level

Alarm

State

Normal

Normal

PULSE, 0.5 Hz

High Alarm

(Sensor 1 and / or

Sensor 2)

Flashing Red, 2 Hz

Display will toggle between ALARM, gas name,

concentration of each sensor until alarm is acknowledged

and concentration falls below High alarm level

Alarm

State

Alarm

State

Normal

PULSE, 2 Hz

Fault Alarm

(Sensor 1 and / or

Sensor 2)

Constant Amber

Display will toggle between FAULT 1 (or 2), gas

name, concentration of each sensor until the fault is

corrected and acknowledged

Normal

Normal

Fault

State

CONSTANT

Off-line

Green > Amber > Red

“oFFLn” is displayed

Off-line

Off-line

Off-line

OFF

1. Connect adapter and gas cylinder according to the

instructions in the General Calibration Procedure.

2. If desired, disable / silence external annunciators

(e.g.,

shutdown valves, notification of authorities, etc.)

:

3. Apply a sufficiently high concentration of the target gas to

trigger alarms, but NOT pure refrigerant or hydrocarbons

(e.g., do not use a butane lighter)

.

4. Once thresholds have been exceeded, relays should activate,

digital outputs should transmit the gas concentration and:

¾

Gas concentration should be displayed, the instrument

status should be “Low Alarm” or “High Alarm” and

alarms states should be “On.”

5. Turn off gas flow and remove the calibration adapter.

6. Allow sensor to recover / stabilize before the instrument

returns to normal operation

(green LED)

.

4. Installation

(Continued)

PN: 1100-XXXX

SN: YYMM####

GAS: CO2

10000 PPM

Part Number

Serial Number

Sensor Type

Max Range

IMPORTANT:

Both tactile (Press or Hold) and magnetic (Tap or

Hold) switches are provided depending on the users method of

interface. Both sets of switches have redundant functions and

can be used to configure, calibrate and maintain the MGS-550.

The following table describes the switches functionality:

STEP 4 |

Reconnect Lid

(Continued)

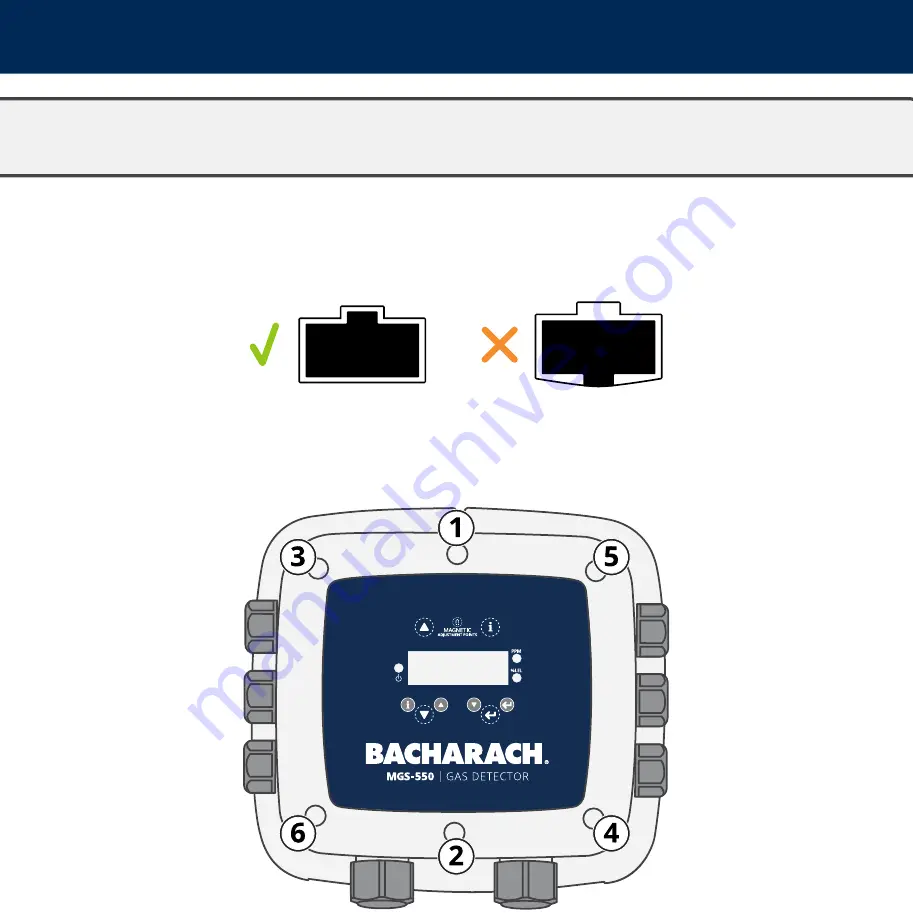

1. Carefully reattach the ribbon cable to J1 as shown in

Internal Wiring Description in Section 2, carefully noting

the keyed position on the connector.

2. Using a 5/32″

(4 mm)

hex key / allen wrench, tighten the

lid screws in an “X” tightening pattern.

IMPORTANT:

If there was a sensor element installed in Step 3,

the sensor needs to be registered with the gas detector.

1. Power up the gas detector. The detector will prompt you to

start the registration. (e.g., “rEg 2”).

2. Acknowledge by tapping [

↵

]. The detector will indicate

a successful registration (e.g., “PASS2”) if the sensor was

correctly installed.

STEP 5 |

Register the New Sensor

6. General Calibration Procedure

6c. Span Adjustment

13.

Press the [UP] / [DOWN] arrows to change the values to match

the concentration of the calibration gas (in the units of the

sensor – i.e., ppm, Vol %, %LEL, etc.) and then press [

↵

].

14. Apply span gas and then press [

↵

].

¾

The display will show the current gas concentration

value blinking in the units of the sensor – i.e., ppm, Vol

%, %LEL, etc. (e.g., “100”).

15. Wait for the current gas concentration value to stabilize.

16. Tap [

↵

] to perform the calibration adjustment.

¾

(The instrument will indicate success status with a

“PASS” display. Otherwise a “FAIL” message is displayed.)

17. Turn off gas flow and remove the calibration adapter from

the sensor or disconnect the tubing.

18. Ensure that the concentration is below the alarm

thresholds.

¾

(For oxygen, ensure that the concentration is below the

enrichment alarm thresholds.)

19. Tap [

↵

] to exit the function.

IMPORTANT:

Refer to MGS-550 User Manual for complete

configuration and operation instructions.