D-BA-0000308.6.4

Operating instructions

Technical data and dimensional drawings

V05 / September 07, 2010

OI-39

7 Technical data and dimensional drawings

7.1 Interference resistance, UL approval

7.1.1 CE compliance

Electromagnetic compatibility EMC

The devices are intended as components for installation in machines and systems.

Adherence to the installation instructions warrants compliance with the

corresponding requirements for CE compliance of the entire machine/system

equipped with such components based on the EMC Directive 2004/108/EC.

Generic standards:

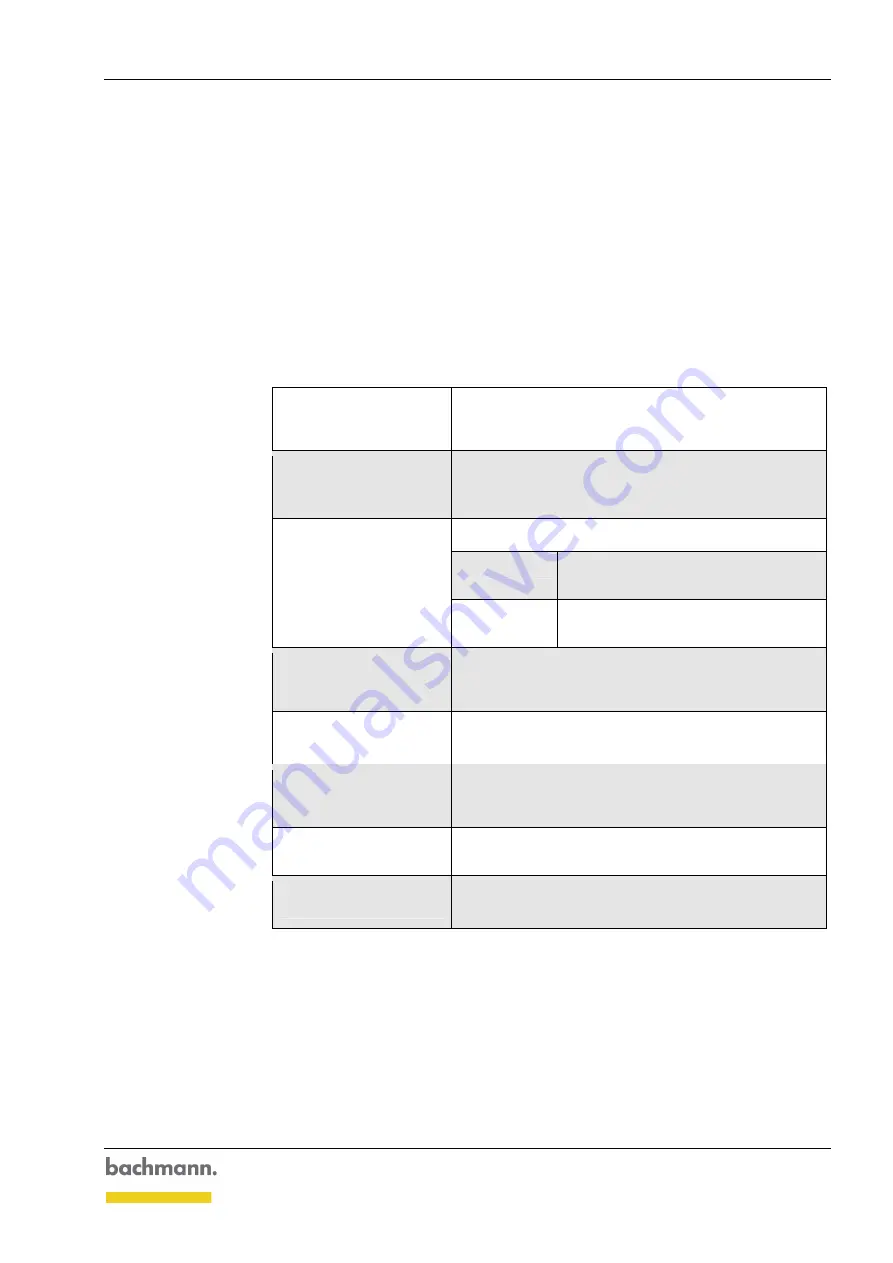

Immunity to interference

industrial environments

According to EN61000-6-2

Interference resistance

against discharge of static

electricity

Tested according to EN61000-4-2 Level 1-3

No malfunction or permanent impairment on the housing and

all interfaces

Tested according to

EN61000-4-3

HF field, AM modulated: 80 MHz to 1 GHz,

10 V/m

Interference resistance

against high-frequency

electromagnetic fields

EN61000-4-6

HF asymmetrical, AM modulated:

150 kHz to 80 MHz, 10 V/m

Interference resistance to

rapid transient electric

disturbances (burst)

Supply tested according to EN61000-4-4 Level 3

Interfaces tested according to EN61000-4-4 Level 4

Interference resistance to

surge voltages

Supply tested according to EN61000-4-5 Level 1

Interfaces tested according to EN61000-4-5 Level 2

Generic standards:

Interference emission

industrial environments

According to EN61000-6-4

Interference emission,

Radio interference

Tested according to EN55011 Class A

Resistance to supply

voltage failure (+24 VDC)

Tested according to IEC 1131-2

≤

10 ms/s without malfunction

Tab. 14: Electromagnetic compatibility (EMC)