1

-

29

FOR YOUR SAFETY

1

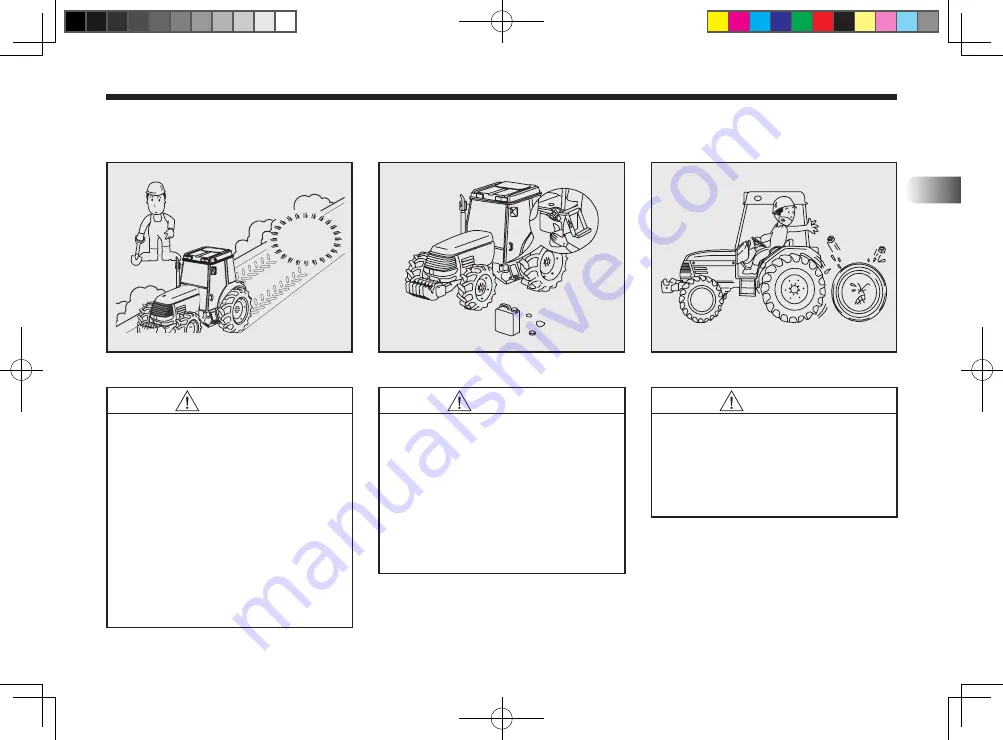

Turn off engine in a level area

when leaving the tractor;

•

When leaving the tractor, park

the tractor on a level and safe

area, turn off the engine, and

apply the parking brake. Also,

lower the implement on the

ground.

If this instruction is ignored, the

tractor may move and cause an

accident.

WARNING

Remove spilled excess fuel after

closing the fuel cap;

•

After filling the fuel tank, close

the fuel filler cap complete-

ly and wipe off the excess fuel

thoroughly.

If this instruction is ignored,

there is a risk of fire.

WARNING

Be aware of the PTO RPM re-

quirements for the implements;

If this instruction is ignored,

there is a risk of accident or in-

jury.

WARNING

BB1022H.indb 29

BB1022H.indb 29

2021-06-28 오후 5:53:17

2021-06-28 오후 5:53:17

Summary of Contents for 1022H

Page 2: ...S BB1022H indb 2 BB1022H indb 2 2021 06 28 오후 5 53 08 2021 06 28 오후 5 53 08 ...

Page 44: ...MEMO BB1022H indb 4 BB1022H indb 4 2021 06 28 오후 5 53 19 2021 06 28 오후 5 53 19 ...

Page 50: ...MEMO BB1022H indb 6 BB1022H indb 6 2021 06 28 오후 5 53 19 2021 06 28 오후 5 53 19 ...

Page 110: ...MEMO BB1022H indb 28 BB1022H indb 28 2021 06 28 오후 5 53 27 2021 06 28 오후 5 53 27 ...

Page 140: ...MEMO BB1022H indb 8 BB1022H indb 8 2021 06 28 오후 5 53 29 2021 06 28 오후 5 53 29 ...

Page 148: ...MEMO BB1022H indb 8 BB1022H indb 8 2021 06 28 오후 5 53 30 2021 06 28 오후 5 53 30 ...