16

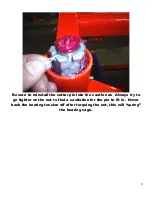

Remove and inspect air cleaner weekly. (more often in dusty

conditions). Do not blow filter out with air pressure, this will cause

the filter to be filled with tiny holes that will allow dirt to enter.

Instead, tap filter on side to remove any debris. Replace at least once

a year, more often in dusty conditions.