FIRST STEPS

Put the badge maker on a table in front of you. In the carton you

separately find the rubber handle - screw it into the operating lever.

Fixing the rubber handle

Put the badge maker in front of you so that

the ground plate is positioned vertically.

Turn the swivelling plate into a horizontal

position, so that you can correctly read the

word „Flexi”.

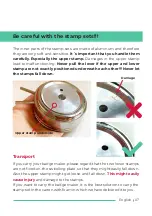

Inserting the stamp set

10

English