SENSOR INSTALLATION

Before installation, configuration or operation, familiarize yourself with the equipment and operating requirements by

reading all sections of this manual . Make sure the site has been thoroughly prepared and is suitable for installation .

Preinstallation Considerations

MPORTANT

I

Remove all process connection caps and make sure process connections are open.

• Support and align piping connections to prevent side loading of the mating surfaces .

• RCS018 and larger sensors are designed to be supported by the process flange connection . No additional supports are

needed for meter housing .

• To reduce the influence of pipe vibration on RCS018 and larger meters, use Stauff style clamps to help with supporting

process piping .

• Mount full port ball valves (isolation valves) on either side of the meter

for zero calibration purposes .

• Mount control valves downstream of the flow meter to prevent possible

cavitation, especially when measuring liquids with low boiling points

(see

.

• Install the sensor in a section of the piping where it always remains full,

unless the application is designed to drain with no flow .

• Vertical piping installations should have the flow going up through the

sensor . See

.

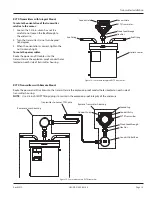

Control Valve

Flow

Figure 8: Control valve location

• When using hose connections, use a short section of rigid pipe on each side of the sensor for proper support . The sensor

should not hang from hose connections . See

and

.

• Use caution with fluids that harden or solidify at rest . Do not pass fluids that react together through the same flow sensor .

Do not cover transmitter with insulation material .

• If heat tracing is used, be aware of the maximum temperature limits of the meter .

• Use of armored hoses as sensor vibration isolators may be required when a high amount of ambient vibration is present

and

.

• Verify that particulate matter is small enough to pass through the flow sensor . Add a filter to the system, if necessary .

• Verify that the flow sensor is earthed/grounded at the earth connector located

on the sensor side . An AWG #10 or larger protective ground must be connected

to the side grounding terminal for the system to work correctly (see

and

)

.

• Avoid high sources of EMF that can be produced by large transformers, large

motors and VFDs without chokes .

THE SENSOR IS PURGED WITH DRY NITROGEN AT THE FACTORY. THE TWO

PURGE PLUGS SHOULD NOT BE REMOVED. IF THEY ARE REMOVED FOR ANY

REASON, RETURN THE UNIT TO THE FACTORY TO BE RE-PURGED AND SEALED.

CONSULT FACTORY FOR SUPPORT.

1

Figure 9: Purge ports

1

Port

Nitrogen purge

Sensor Installation

Page 10

April 2019

CRL-QS-01552-EN-05