SENSOR CHECK

It is important to check that the sensor and transmitter are correctly matched . Unmatched sensor and transmitter pairs will

produce inaccurate readings .

To check that the correct sensor has been connected to the correct transmitter, refer to the calibration documents that

are sent with the meter system . The Flow Calibration Report includes vital information pertaining to the specific sensor and

transmitter pair . Under “Product Information” there are fields for both sensor and transmitter model number and

serial number .

Look at the outside of the sensor and transmitter and locate the serial tags . Pair the transmitter to the appropriate sensor by

matching the serial numbers as indicated on the calibration report .

After the transmitter is powered on, make sure the calibration constants entered into the transmitter match the information

provided on the serial tags and the calibration documents .

• Flow Factor (FloFct): Main Menu > Set Up > Calibration > Flow

• DAlpha: Main Menu > Set Up > Calibration > Density

• DBeta: Main Menu > Set Up > Calibration > Density

If the numbers entered in the transmitter do not match what was provided on the serial tags and the calibration report,

contact the factory for assistance .

INITIAL ZEROING PROCEDURE

Priming for Zero

This procedure requires a password level of Operator or higher .

The flow sensor must be completely full at stable process temperature and pressure before zeroing the system .

Even if the flow sensor has already been filled, circulate fluid for a minimum of 10 minutes at a flow rate greater than 20% of

the rated full scale value of the flow sensor to purge both the process piping and sensor of air .

OTEE:

N

Do not attempt the initial startup procedure with a partially filled sensor .

OTEE:

N

If the process temperature or pressure changes significantly, the meter may need to be re-zeroed . If the meter is to be

re-zeroed, make sure the meter is completely full and flow is shut off by first closing the downstream blocking valve

and then the upstream blocking valve to prevent the potential for cavitation in the sensor . Stopping the pump or

relying on check valves does not ensure the zero flow condition necessary to perform the system zero .

Zeroing the System

OTEE:

N

The system must be zeroed after installation and before normal operation .

1 . Run flow through the sensor at the highest possible rate for several minutes to eliminate any entrained gases in

liquid systems .

2 . Stop all flow and close the downstream and upstream blocking valves . Close the downstream valve first to prevent

draining of the system .

3 . From the

Home

screen, press

Menu

to enter into the top level menus .

4 . Use

Up

or

Down

to scroll through the list until

SET UP

appears in the active line, then press

Enter

.

5 . Use

Up

or

Down

to scroll through the list until

CALIBRATION

appears in the active line, then press

Enter

.

6 . Use

Up

or

Down

to scroll through the list until

ZERO CALIBRATION

appears in the active line, then press

Enter

.

7 . Use

Up

or

Down

to scroll through the list until

START ZERO

appears in the active line .

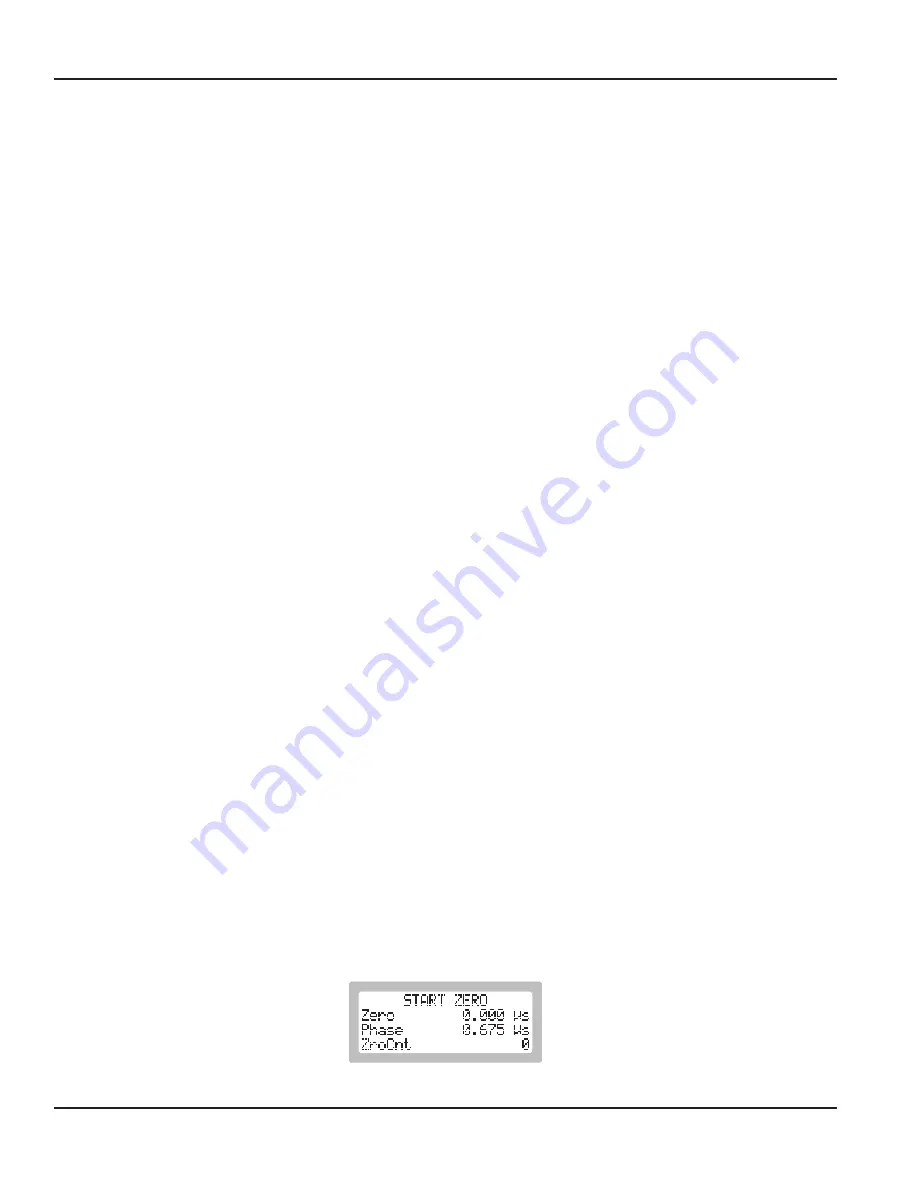

Figure 43: Start zero screen

8 . Press and hold

Enter

to initiate a zero calibration .

Sensor Check

Page 28

April 2019

CRL-QS-01552-EN-05