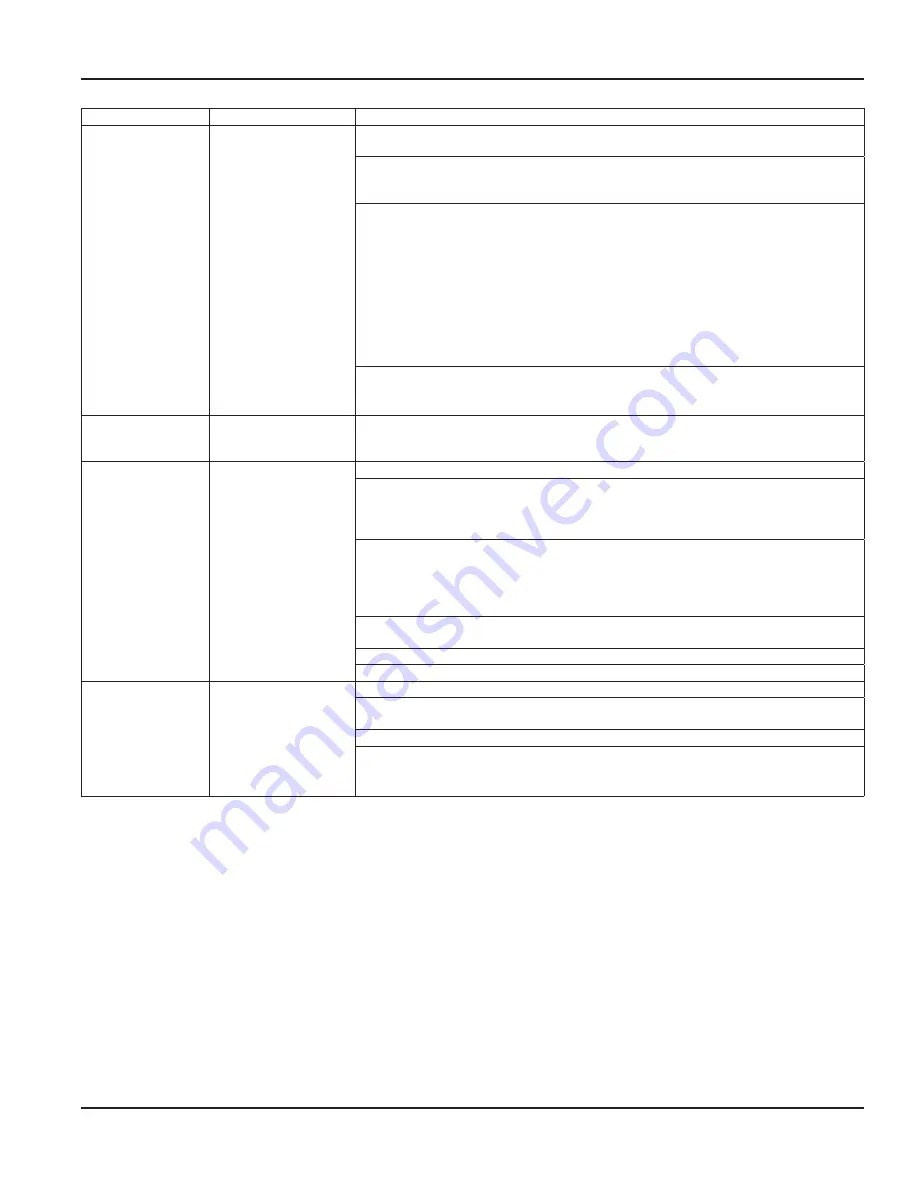

Symptom

Possible Cause

Recommended Action

Density reading

appears to be

incorrect

Installation issues

Process loop issues

Incorrect

parameter settings

Check process loop for entrained air and concentration of mix fluids which will impact

the density .

Run HealthTrack, the advanced function in RCT Console configuration software, to record

critical measurements . Multiple, vital parameters can be viewed in a single snapshot to

assist with diagnosing issues .

Check for mechanical vibrations . Impact of mechanical vibrations might be visible in

the parameters .

System > Sensor >

DrvOut

and

Freq

(tube frequency) readings .

DrvOut

should be between

10…95% and

Freq

should be between:

• 90…115 Hz (RCS005)

• 170…220 Hz (RCS008)

• 80…110 Hz (RCS018…050)

• 40…90 Hz (RCS100…300)

OTEE:

N

The frequency stability should be better than ± 0 .01 Hz for a

good measurement

Verify that the calibration factors on the sensor are entered correctly to the transmitter:

• Set Up > Calibration > Flow >

FloFct

(Flow Factor)

• Set Up > Calibration > Density parameters:

DAlpha

and

DBeta

Volumetric flow

reading appears to

be incorrect

Mass or density

readings are incorrect

Volumetric flow rate is calculated the mass flow rate divided by the density:

vFlo = mFlo/Dens

Sensor temperature

(Temp1) reading

appears to be

incorrect

Incorrect wiring

Cable issue

RTD not functioning

Verify sensor RTD is properly wired to transmitter (pins 2, 3 and 4) .

At the transmitter, disconnect the sensor wiring . Measure the resistance between brown

and yellow/gray sensor wires . The resistance should be approximately 110 Ohms at

77° F (25° C) . The resistance will vary depending on the fluid temperature . The resistance

between the yellow and gray sensor wires should be less than 5 Ohms .

If there appears to be an open or short at the transmitter end of the cable, remove the

sensor cable from the sensor and measure the resistance from pin J to pins G/H on the

sensor . The resistance should be 80…100 Ohms for temperatures less than 32° F (0°

C) and 100…180 for temperatures greater than 32° F (0° C) . Depending on the fluid

temperature, the resistance between pins G and H should be less than 1 Ohm .

Check the RTD Calibration constants in

Set Up > Calibration > Temperature

.

RTD1Of

should

be 0 (± 5) .

RTD1Sl

should be 1 .00 (± 0 .1) .

If there appears to be an open or short at the pins, replace the sensor .

If the sensor measurements are in the acceptable range, replace the sensor cable .

Current, frequency,

pulse or PWM

outputs do not

match the readings

Incorrect

parameter settings

Wiring

configuration issues

Control system

configuration issues

See

"Output Configuration" on page 32

for parameter settings .

Check that the ID parameter for the output matches the parameter of the

desired reading .

Verify that the minimum and maximum parameters for the output are set properly .

Verify the device reading the output is set up correctly . The current and frequency

outputs have a test output (

TstOut

) that can be used to troubleshoot system issues .

Table 3: Troubleshooting symptoms/resolution

Troubleshooting

Page 39

April 2019

CRL-QS-01552-EN-05