10

10

11

Electrical Installation

Access wiring terminals by removing side cover. A wiring diagram is on the side cover, under the gasket. Use care

when replacing side cover to insure that the gasket is in place.

DO NOT REMOVE CIRCULAR COVER

from top of sensor. You may disturb seal and label alignment.

A moisture absorbing silica pack has been placed inside the electronics housing during assembly. Leave in place after

making wire connections.

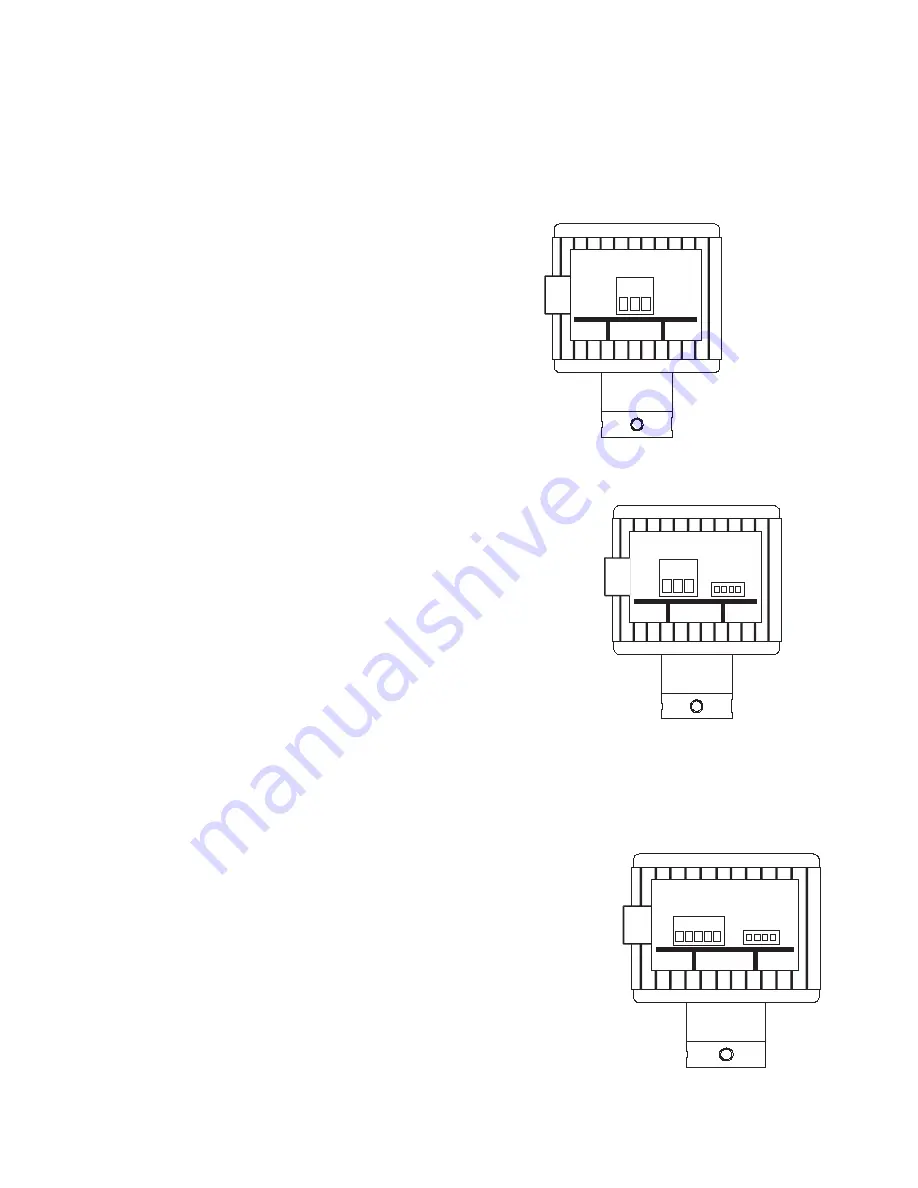

Standard frequency (Pulse) output

- Option “0” in the

ordering matrix

This two wire sensor is intended for connection to Data Industrial

monitors and transmitters or other devices that supply 10-24 DC

excitation voltage and accept frequencies from 0 to 1000Hz.

Attach the sensor shield terminal 1 to the shield terminal on the

transmitter (used for maximum protection from interference).

Attach the sensor common terminal 2 to the common (-) terminal

on the transmitter.

Attach the sensor signal terminal 3 to the signal (+) terminal on the

transmitter.

Analog 4-20mA Output

- Option “1” in the ordering matrix

This option provides a programmable 4-20 mA signal proportional to flow

rate. All programming is accomplished as previously mentioned. The user

can program the unit for pipe size, flow scale. This is a two-wire option.

Attach

SDI #1

(Shield)

to Earth Ground or Power Supply Common. (This

provides maximum power and signal EMI protection).

ANALOG OUTPUT – WIRED AS CURRENT SINKING

Attach

SDI#2 (Loop -)

to the Analog input terminal of device receiving this

4-20mA signal.

Attach

SDI#3

(Loop +)

to +24VDC terminal of device receiving the 4-20mA

Signal.

ANALOG OUTPUT – WIRED AS CURRENT SOURCING – (WITH SEPA-

RATE 24VDC POWER SUPPLY)

Attach

SDI#2

(Loop -)

to Analog input terminal of device receiving this

4-20mA signal. (Sometimes labeled Loop

+

).

Attach

SDI#3

(Loop +)

to +24VDC Supply terminal.

Attach -24VDC Supply terminal to the Analog Input Common. (Sometimes labeled Loop

-

).

Scaled Pulse output

- Option “2” in the ordering matrix

This option provides a programmable opto-isolated solid state switch closure

with internal solid state fuse protection. All programming is accomplished as

previously mentioned. The user can program the unit for pipe size, flow scale

and the direction of flow. This is a six-wire option.

Attach

SDI #1

(Shield)

to Earth Ground or Power Supply Common. (This

provides maximum power and signal EMI protection).

Attach

SDI #2

(Power -)

to the negative terminal of a nominal

12-24VAC/VDC Power Supply. (See data sheet for current draw and voltage

limits).

Attach

SDI#3

(Power +)

to positive terminal of power supply.

Attach

SDI #4

(Pulse -) to the Input pulse (-) of the receiving device.

Attach

SDI #5

(Pulse +) to the Input pulse (+) of the receiving device.

1. Shield

2. Power -

3. Power +

4. Pulse -

5. Pulse +

1 2 3 4 5

1 2 3

1. Shield

2. Loop -

3. Loop +

1 2 3

1. Shield

2. Sensor Common

3. Sensor Signal