Page 7

For technical questions, please call 1-888-866-5797.

Item 56385

SAF

eT

y

O

Pe

RA

Ti

O

n

M

A

in

Ten

A

n

C

e

Se

Tu

P

Mounting the Winch

1. Make sure the Winch will fit the chosen mounting

area. If relocating the Control Box is necessary

or desired, perform the removal and installation

of cables to the Winch before mounting. Refer

to

Relocating the Control Box

on page 8.

2. The mounting plate must be rated to

at least the Winch’s capacity.

3. Align the Winch perpendicular to center line of

the vehicle at the desired location, and mark the

locations of the winch base holes. Compare the

dimensions of the marked holes to Figure A.

4. Before drilling, verify that the installation

surface has no hidden components or

structural pieces that will be damaged.

nOTe:

This Winch can generate extreme

forces. Select a location that can withstand the

rated capacity without damage or weakening.

Steel reinforcement plates may be needed or a

certified welder may need to weld on additional

bracing depending on the mounting location.

5. Drill holes appropriate for the hardware

at the marked locations.

note:

Depending on the vehicle application, it may

be beneficial to install the wiring before mounting

the Winch. Check all terminal access and plan

wiring routes before mounting the Winch.

6. Install the Winch using hardware specified

on the specification chart. Tighten fasteners

to the following torque values:

Winch mounting fasteners

30 –33 ft-lb

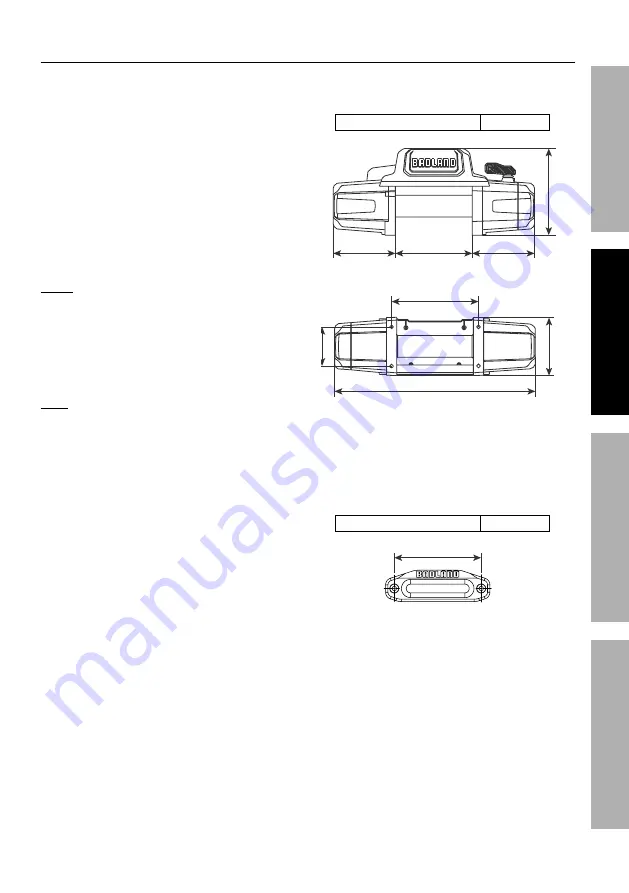

8.82 in. / 224 mm

7.2 in. / 183 mm

7.2 in. / 183 mm

10.0 in. / 254 mm

10 in. / 254 mm

23.2 in. / 590 mm

6.50 in. / 165.0 mm

4.49 in. / 114 mm

Figure A: Winch Dimensions

7. Mount the Fairlead centered on the Winch

to guide the Rope onto the Winch drum.

8. Install the Fairlead using hardware specified

on the specification chart. Tighten fasteners

to the following torque values:

Fairlead mounting fasteners

53 – 57 ft-lb

10 in. / 254 mm

Figure B: Fairlead Mounting Dimensions