BA_375-E42_01_DEF_MJ_4419

11 |

32

W. Baelz & Sohn GmbH & Co.

· Koepffstrasse 5 · 74076 Heilbronn · Germany ·

www.baelz.de Seite | Page

Motorized Rotary Actuator

baelz 375-E42

5. COMMISSIONING

Compare the actuator torque and the set travel with the technical specifications of the valve.

Overloading can lead to serious damage to the valve. Watch out for moving parts during

assembly and adjustment. Risk of injury and substantial material damage.

The rotary actuator is factory set to a rotational travel of 90°.

Actuators with positioners are supplied with a control input signal of 0-10

unless otherwise stipulated upon ordering.

Caution

5.1 Setting the mechanical end stops

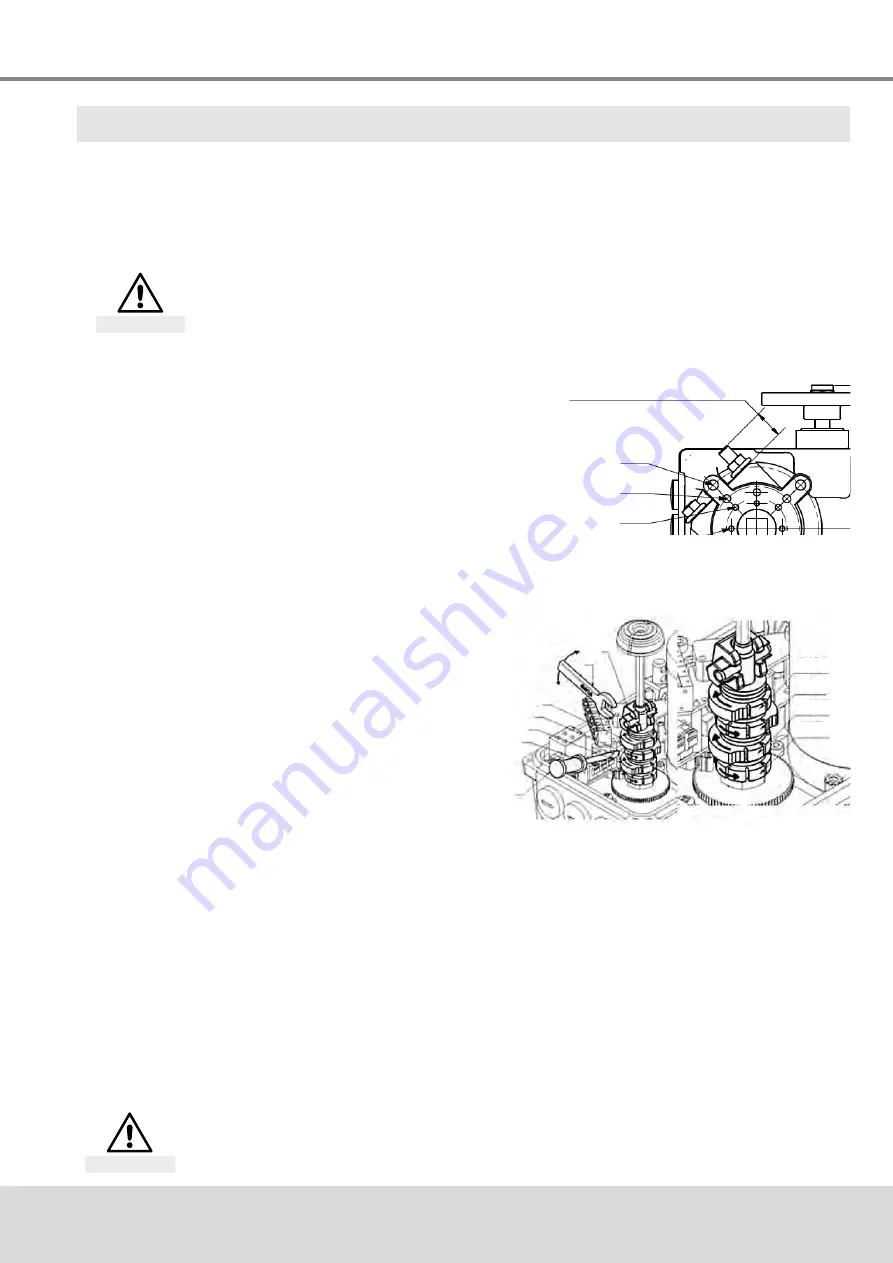

Move the actuator out of the end position, tighten

the stop screw to the dimension shown in Fig. 3 and

counter-tighten the nut. The stop screw should not

be turned out of the specified range. If the range is

exceeded, rotate the coupling by one tooth relative to

the output shaft.

Fig. 3: Setting the mechanical end

stops

5.2 Setting the limit switches

Move actuator into chosen end position. Open the

eccentric tappet (1) using a 10 mm wrench and

adjust the switch cam with a screwdriver (7). Close

the eccentric tappet again using the wrench (

Use of the limit switches to switch off the actuator

will prolong its lifespan.

Fig. 4: Setting the limit switches

5.3 Test run

5.3.1 Checking the direction of rotation

●

Adjust the actuator manually to roughly the middle position.

●

In direction of travel CLOSE, switch the actuator on and watch the direction of rotation.

●

If the direction of rotation is wrong, switch off immediately.

● Check wiring (jumpers).

●

Repeat the test run.

~ 19 mm for 90°

(Min: 12,9 / Max: 25,1) ±15°

F05

F07

F10

EZ2

EZ1

WER

WEL

unlock

lock

1

6

2

3

4

5

7

If the direction of travel is set incorrectly, damage to actuator and valve is

imminent as the limit switches will not function with the wrong direction of

rotation!

Attention