Page 20/24

Operating Instructions

BA 7020

Technical specifications subject to change without notice

Copyright according to ISO 16016

7. ERRORS

7.1 Error after an initialisation run

Following a successful initialisation run, only the green LED is lit.

If the red LED is flashing, this indicates an error following an unsuccessful initialisation run. The first error to

occur during initialisation is shown. If the green LED is lit, the unit had already been initialized before the current

initialisation run. If the green LED is flashing, the unit had not been successfully initialized previously.

The red LED shows errors occuring during initialisation as follows:

Error code 1: interval interval etc.

Error code 2: interval interval etc.

etc. up to ...

Error code 8: interval interval etc.

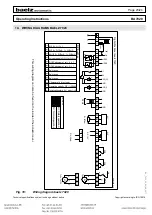

Fig. 14:

Initialisation error codes

7.2 Error during initialisation or during normal positioner operation?

Following an initialisation run, the red LED shows only initialisation errors as long as DIP switch 12 is set to 1.

This enables a clear differentiation between errors occuring during initialisation and those occuring during normal

positioner operation. Setting DIP switch 12 from 1 back to 0 permits the red LED to show any normal operational

errors instead of initialisation errors which may have occured.

Error code

Error

Corrective action

1 →

1 x

Invalid status of initialisation run. Possible

cause: EMI (electromagnetic interference).

Remove source of interference.

2 →

2 x

Sensor malfunction at analogue input AI1:

No signal from potentiometer.

Check connection terminals 91, 92, 93

(see wiring diagram chapter 10).

Replace potentiometer if necessary.

3 →

3 x

Potentiometer value at AI1 too small.

Possible cause: EMI.

Remove source of interference.

Replace potentiometer if necessary.

4 →

4 x

Potentiometer value at AI1 too large.

Possible cause: EMI.

Remove source of interference.

Replace potentiometer if necessary.

5 →

5 x

Wrong direction of travel

Check motor (97, 98, 99) and potentiometer

(91, 92, 93) connections (see wiring

diagram chapter 10).

Remove source of interference.

6 →

6 x

Obstruction: potentiometer or motor not

moving.

Check connections, set N↔S switch to "N",

remove any obstructions.

7 →

7 x

Stroke too long.

Fit actuator to a valve with nominal stroke

length < 22 mm.

8 →

8 x

Stroke too short.

Fit actuator to a valve with nominal stroke

length > 8,7 mm, remove any obstructions.