!

GEN3-1

7.

Stable and horizontal.The steam generator has a hanging groove for immobility on wall.

Make

sure the machine is steady and horizontally installed.

8.

On both sides and the top of the steam generator need to reserve at least 12 inches space.

9.

The place where the machine is installed must be easily cleaned up and convenient for the

disassembly of the machine.

10.

The installation place must be convinent for the drain of water in inner pot.

11.

The steam tube,safty valve, drain valve,water tube,steam outlet are still very heated after

the steam generator have stopped working for some time.Must take some measures for example

using the heat insulation tube to prevent the damage of the hot tube and keep the outlet

away from the people.

12.

The controller must be installed in the steam room,please refer to the

chapterinstruction of the controller's installation and operation of the manual.

The steam generator(including the controller) are comply with the CE and UL

certificate,

and are adaptive in the moisture environment.

!

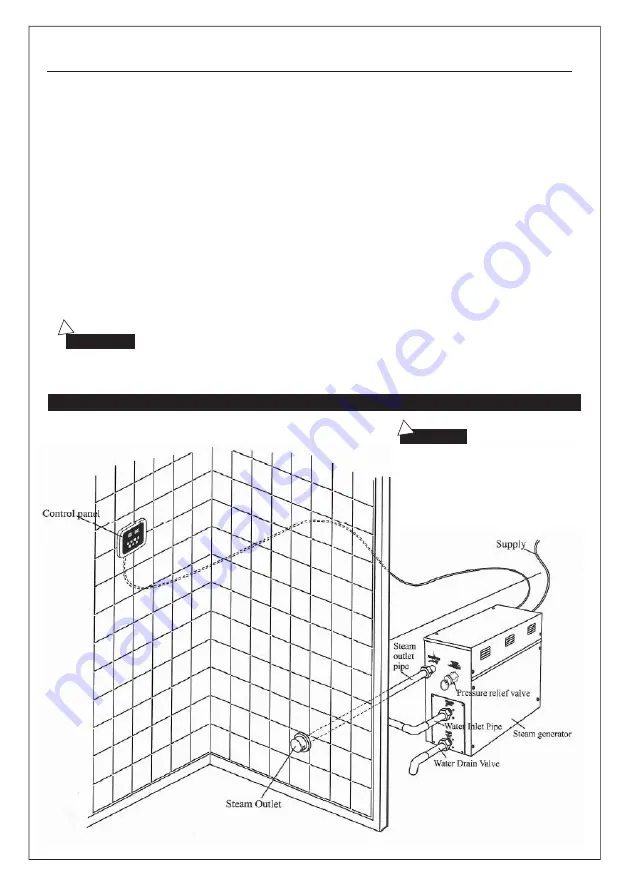

Installation drawing of the steam generator

Attention

:

The drawing is only for explanation.

As for practical design of steam

room, please consult with qualified

designer or architect.

Attention: