56

56

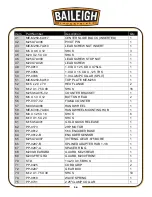

Item

Part Number

Description

Qty.

41

ME-M250-6A017

CENTER SLIDE BLOCK (INSERTED)

1

42

M250-7A006

PIVOT PIN

1

43

ME-M250-7A010

LEAD SCREW NUT INSERT

1

44

M5 X 0.8 X 12

SHCS

3

45

M20 X 2.5 X 40

SHCS

1

46

M250-7A009

LEAD SCREW STOP NUT

1

47

M200-7A023

LEAD SCREW

1

48

PP-0913

1.0 ID X 1.25 OD X 0.75LG

1

49

PP-0056

1.0 ID X 1.5 OD X .125 THK

1

50

PP-0036

1.0 CLAMP COLLAR (SPLIT)

1

51

ME-M250-6A010

TOP PLATE ME-M250

1

52

M16 x 2.0 x 70

HEX FLANGE

2

53

M12 X 1.75 X 90

SHCS

16

54

M250-6A015-V2

COUNTER BRACKET

1

55

M6 X 1.0 X 12

BUTTON HEAD

2

56

PP-0137-V2

FIAMA COUNTER

1

57

M300-6A066

HAND WHEEL

1

58

ME-M300-7A034

HANDWHEEL MOUNTING HUB

1

59

M8 X 1.25 X 16

SHCS

6

60

M10 X 1.5 X 20

SHCS

1

61

M150-5A001

GOLD QUICK RELEASE

1

62

PP-0173

2HP MOTOR

1

63

PP-0812

56C ENCODER BASE

1

64

PP-0812-B

ENCODER SENSOR

1

65

M250-7A007

38T RING GEAR .875 BORE

1

66

PP-0297-B

SPLINED ADAPTER HUB 1-1/8

1

67

PP-0297-A

SPACER RING

1

68

M200-REARGRD

GUARD, M325 REAR

1

69

M200-FRTGRD

GUARD, M200 FRONT

1

70

STD.

1/4-20 X 0.5 BHCS

3

71

PP-0025

CORD GRIP

2

72

PP-0297

GEAR BOX

1

73

M12 X 1.75 X 30

SHCS

10

74

PP-0819

WAVE SPRING

1

75

PP-0731

2.25"CLAMP COLLAR

1

Summary of Contents for B8085

Page 14: ...11 11 GETTING TO KNOW YOUR MACHINE A B C D E F G H I J K L M N...

Page 29: ...26 26 OEM Screen Figure 14 OEM Screen Figure 15 OEM Screen Figure 16 OEM Screen Figure 17...

Page 30: ...27 27 OEM Screen Figure 18 OEM Screen Figure 19 OEM Screen Figure 20 OEM Screen Figure 21...

Page 31: ...28 28 OEM Screen Figure 22...

Page 45: ...42 42 INDEX TABLE LAYOUT DIAGRAM OPTIONAL EQUIPMENT...

Page 52: ...49 49 Diagram 1...

Page 53: ...50 50 Diagram 2...

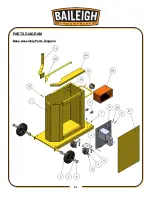

Page 54: ...51 51 PARTS DIAGRAM Base Assembly Parts Diagram...

Page 55: ...52 52 Control Box Parts Diagram...

Page 56: ...53 53 Drive Assembly Parts Diagram...

Page 57: ...54 54 Main Bending Assembly Parts Diagram...

Page 61: ...58 58...