37

37

0.19"

approx.

Blade

Wheel

Blade

Teeth

5. Turning the setscrew (C) clockwise (cw) will tilt the flywheel so that the blade will ride closer

to the flange.

6. Turning the setscrew (C) counterclockwise (ccw) will tilt

the flywheel so that the blade will ride away from the

flange. (If it rides too far away it will come off).

7. After the adjustment is finished, tighten the socket cap

screws (A) first and then the cap screws (B).

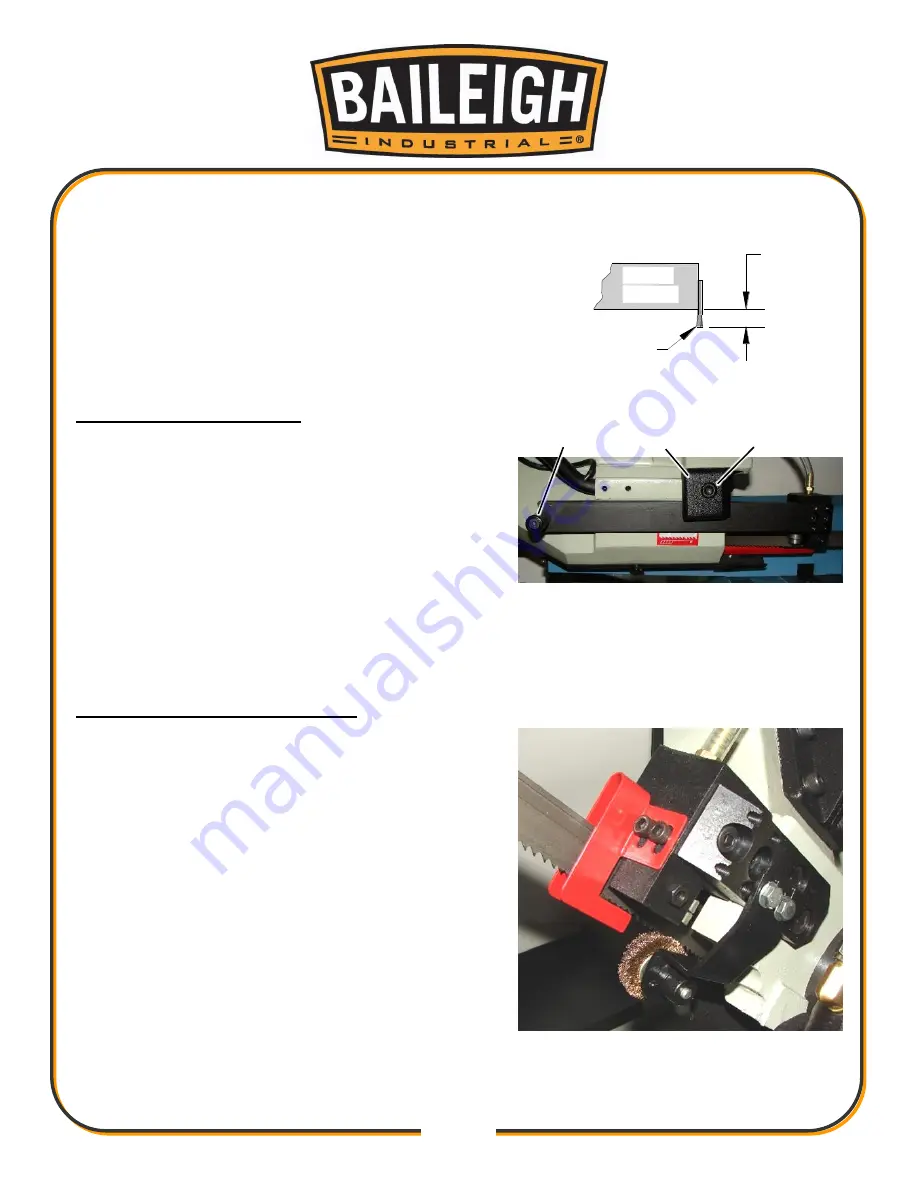

Adjusting the Blade Guide

1. Disconnect the saw from the power supply.

2. Loosen the socket cap screw (A) which releases

the clamping block (B) allowing the extension bar

(C) to slide in and out.

3. Hold the handle (D) and slide the extension bar in

or out to position the blade guide block as close

as possible to the piece part without interfering

with the cut.

4. Tighten socket screw (A) clockwise (cw).

Blade Guide Bearing Adjustment

ATTENTION: This is the most important adjustment

on your saw. It is impossible to get satisfactory work

from your saw if the blade guides are not properly

adjusted.

Your Baileigh Band Saw has been adjusted and

power tested before leaving the factory to insure

proper setting.

If the guides do get out of adjustment, it is extremely

important to re-adjust immediately. An improperly

adjusted blade will not cut straight, and serious blade

damage may result.

It is always best to try a new blade to see if this will

correct poor cutting before beginning to adjust the

blade guide bearings.

If the blade becomes dull on one side and not the

other, for example, it will begin cutting crooked. A blade change will correct this problem; the

guide adjustment will not. If a new blade does not correct the problem, check the clearance

between the blade and guides.

A

B

D

C

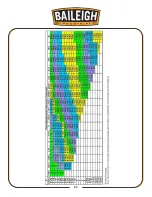

Summary of Contents for BS-350SA

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE I H G F E D C B A T P O Q S M N U L R V J K T...

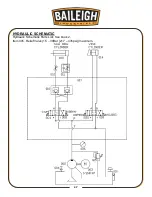

Page 36: ...33 33...

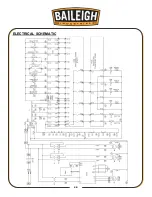

Page 49: ...46 46 ELECTRICAL SCHEMATIC...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...