51

51

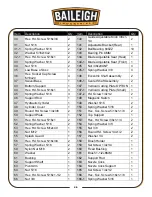

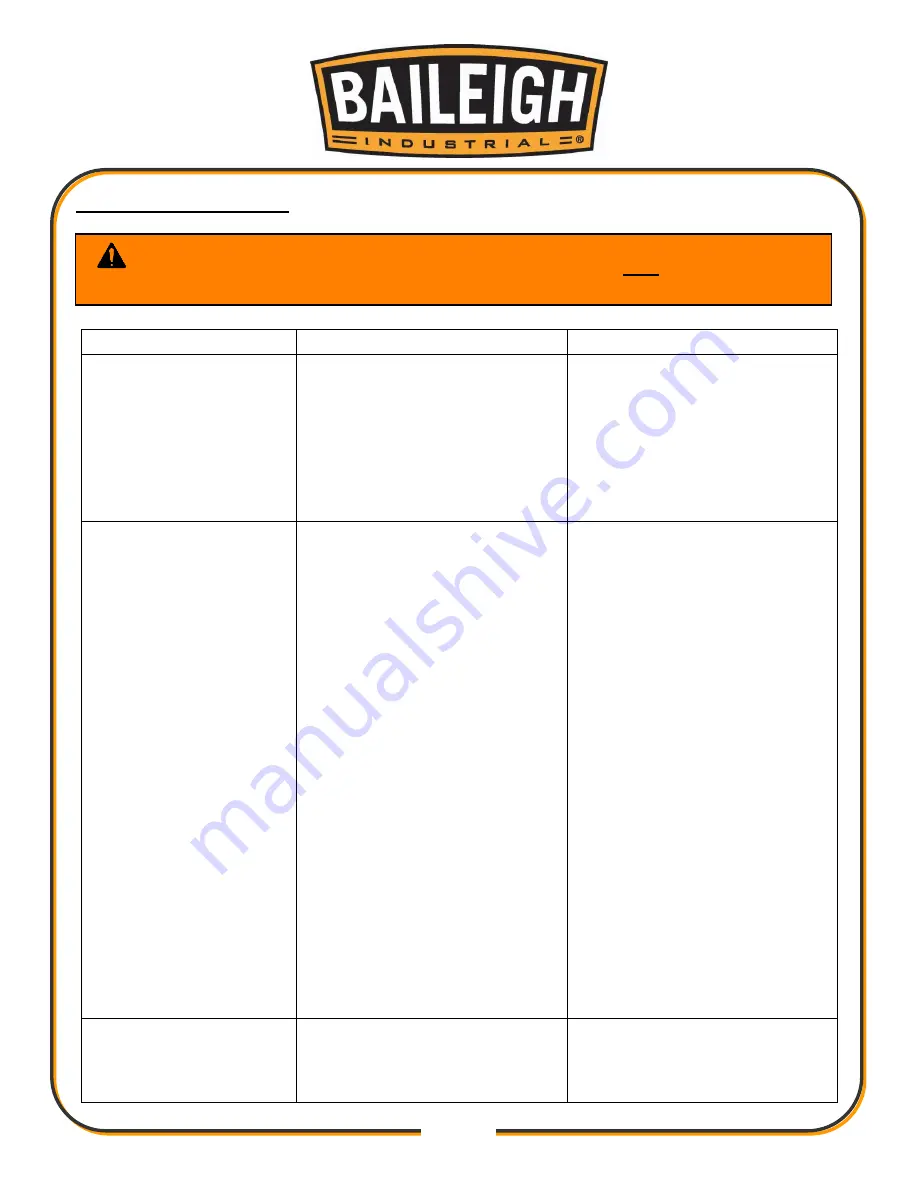

TROUBLESHOOTING

SYMPTOM

POSSIBLE CAUSE (S)

CORRECTIVE ACTION

The Blade Drive Motor

Does Not Work

1. E-stop pushed.

2. No power at the electrical

outlet

3. Motor burned out.

1. Twist the button (cw) to reset

or replace the switch.

2. Have electrician check

breaker or fuses.

3. Have motor repaired or

replaced.

Excessive Blade

Breakage

1. Incorrect blade tension.

2. Incorrect speed or feed.

3. Material loose in vise.

4. Blade rubs on wheel flange.

5. Teeth too coarse for material.

6. Teeth in contact with the

material before the saw is

started.

7. Misaligned guides.

8. Blade too thick for wheel

diameter.

9. Cracking of blade weld.

1. Adjust to where blade just

does not slip on wheel.

2. Consult machine chart or

handbook.

3. Clamp work securely.

4. Adjust the wheel alignment.

5. Contact Baileigh Industrial for

recommended blade type.

6. Contact material after blade

has been started.

7. Adjust as necessary.

8. Select a thinner blade (.035”

x .75” recommended).

9. Make longer annealing cycle

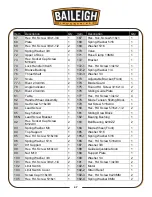

Teeth Ripping from Blade

1. Tooth too coarse for work.

2. Too heavy feed / too slow

feed.

1. Use a fine tooth blade.

2. Increase feed pressure and /

or speed.

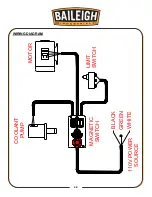

WARNING:

Make sure the electrical disconnect is OFF before working on

the machine.

Summary of Contents for BS-712MS

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE A B C D E F G H I K J L...

Page 32: ...29 29...

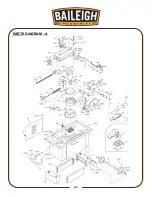

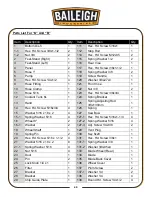

Page 46: ...43 43 PARTS DIAGRAM A...

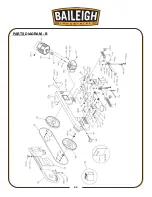

Page 47: ...44 44 PARTS DIAGRAM B...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...