52

52

3. Vibrating piece part.

4. Gullets loading with chips and

debris.

3. Make sure work is clamped

securely.

4. Use coarser tooth blade or

brush to remove chips and

debris.

Premature Blade Dulling.

1. Teeth too coarse.

2. Too much speed.

3. Inadequate feed pressure.

4. Hard spots in or on material.

5. Work hardening of material

(especially stainless steel).

6. Blade installed backwards.

7. Insufficient blade tension.

1. Use a finer tooth blade.

2. Try next slower speed.

3. Decrease spring tension on

side of saw.

4. Scale: Reduce speed,

increase feed pressure. Hard

spots: Increase feed pressure.

5. Increase feed pressure by

reducing spring tension.

6. Remove blade twist inside out

and reinstall blade.

7. Increase tension to proper

setting.

Bad Cuts (Crooked)

1. Work not square.

2. Feed pressure too great.

3. Guide bearing not adjusted

properly.

4. Inadequate blade tension.

5. Blade guides spaced out too

far.

1. Adjust vise to be square with

blade.

2. Reduce pressure by

increasing spring tension on

side of saw.

3. Adjust guide bearing to .001”

greater than max. thickness,

including weld of the saw blade.

4. Increase blade tension a little

at a time. (Center of blue area

on label)

5. Move guide as close to work

as possible without interference.

Summary of Contents for BS-712MS

Page 17: ...14 14 OVERALL DIMENSIONS...

Page 18: ...15 15 GETTING TO KNOW YOUR MACHINE A B C D E F G H I K J L...

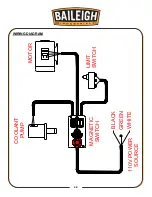

Page 32: ...29 29...

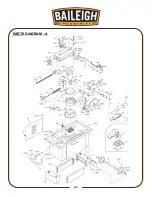

Page 46: ...43 43 PARTS DIAGRAM A...

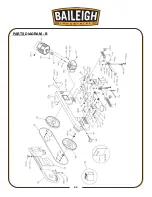

Page 47: ...44 44 PARTS DIAGRAM B...

Page 58: ...55 55 NOTES...

Page 59: ...56 56 NOTES...