21

21

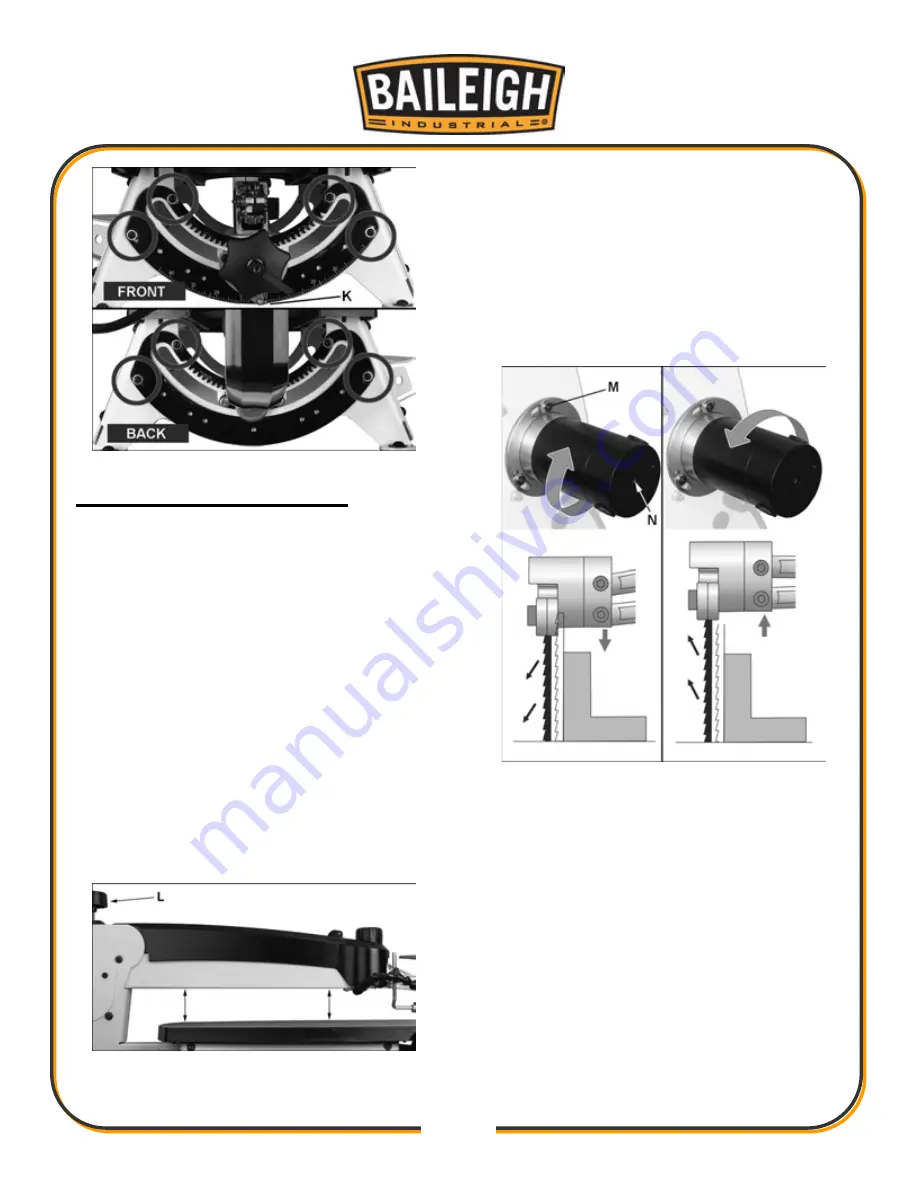

Figure 19: Squaring Blade to Table

Adjusting Blade Oscillation

Refer to Figure 20.

Blade movement can be adjusted to accommodate

different wood stock and types of operations. For

example, for faster, more aggressive cutting the blade

can be adjusted for slight backward movement on the

upstroke, and slight forward movement into the wood

on the downstroke. For slower, fine detail work and

more control, completely vertical blade movement is

often preferred.

This adjustment is based upon user’s preference; as

the scroller gains experience, he/she will get a feel for

the oscillation that is most efficient for the work at

hand.

1. Turn off saw and remove blade.

2. First verify that upper arm is parallel to table

surface (Figure 20). Push arm down, and measure

at front and back of arm; if measurements are

different, rotate arm adjustment knob (L) until

upper arm is parallel.

Figure 20: Arm/Table Parallelism

3. Install blade. Adjustments to blade oscillation can

be subtle; place a square or block of wood on table

and alongside blade as reference.

4. Loosen screws on motor flange (M, Figure 21) with

4mm hex wrench.

Only loosen screws enough to

allow motor rotation.

5. Turn motor shaft (N, Figure 21) with flat-blade

screwdriver

to

observe

blade

motion.

Alternatively, you may turn on saw to slowest

speed to observe blade motion.

Figure 21: Blade Oscillation

6. Slowly rotate entire motor by hand to adjust

oscillation. Clockwise rotation will make blade

movement more aggressive on downstroke.

Counterclockwise will make blade more

aggressive on upstroke. See Figure 21.

TIP: If more rotation is needed,

turn off saw

and

install motor mount screws in second set of holes

behind motor flange.

7. When desired oscillation is achieved, securely

tighten motor mount screws (M).