24

24

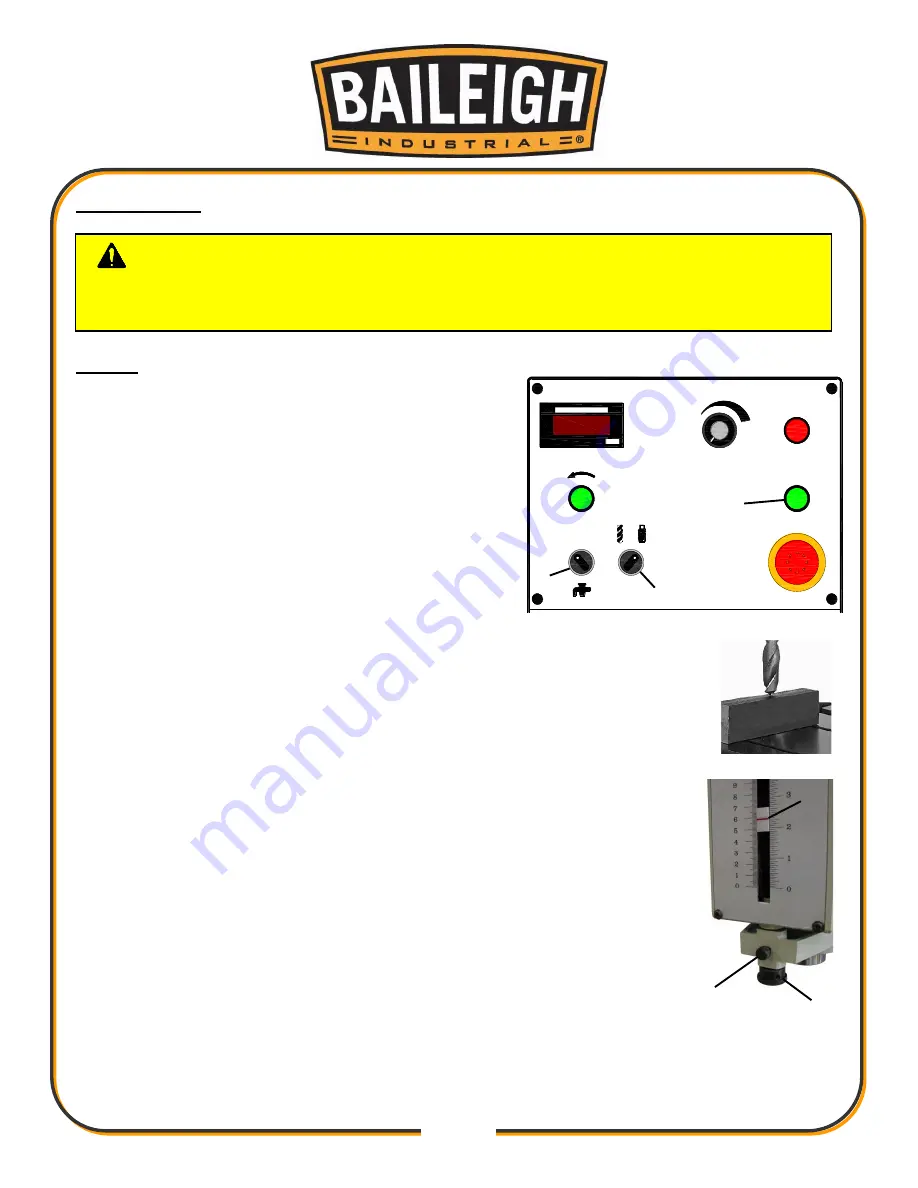

OPERATION

Drilling

1. Load and secure the piece part to the table.

2. Secure drill bit in the chuck.

3. Unlock the table, adjust to the desired height, and

relock the table.

4. Adjust the safety guard up or down as needed.

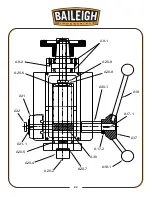

5. Select drilling mode with selector switch (A).

Selector switch (A) shown in tap position.

6. Set the drill bit depth to zero position by lowering it

to the top surface of the piece part, using the down-feed handles.

7. While holding the zero position, turn the depth scale lock knob (B)

counterclockwise (ccw) to release depth stop knob (C).

8. Rotate Knob (C) to set the drill depth on the scale with indicator (D).

9. Re-tighten lock knob (B).

10. Start machine by pressing start button (E).

11. Turn on the coolant selector switch (F).

12. Begin drilling using the down-feed handles to lower the chuck.

13. When the desired depth has been reached, return the down feed

handle to the up position. Do Not allow the handle to spin free back

to the up position.

14. Press the Red Stop button to stop the drill motor.

15. Wait for the spindle to come to a full stop before opening the chuck

guard and reaching into the drill area.

CAUTION:

Always wear proper eye protection with side shields, safety

footwear, and leather gloves to protect from burrs and sharp edges. When handling

large heavy materials make sure they are properly supported.

C

B

D

E

A

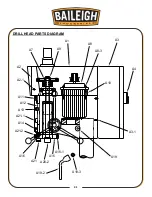

F

DIGITAL INDICATOR

RPM

0

l

150-3000RPM

0

l

SPINDLE SPEED

Summary of Contents for DP-1000VS

Page 19: ...16 16 OVERALL DIMENSIONS ...

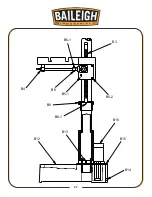

Page 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

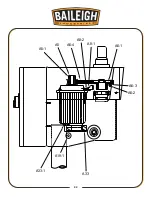

Page 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

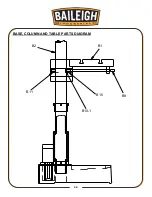

Page 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Page 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

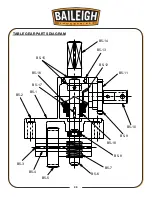

Page 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Page 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

Page 48: ...45 45 CHUCK GUARD PART DIAGRAM ...