25

25

Tapping

1. Load and secure the piece part to the table.

1. Secure tapping tool in the chuck.

2. Unlock the table, adjust to the desired height, and

relock the table.

3. Adjust the safety guard up or down as needed.

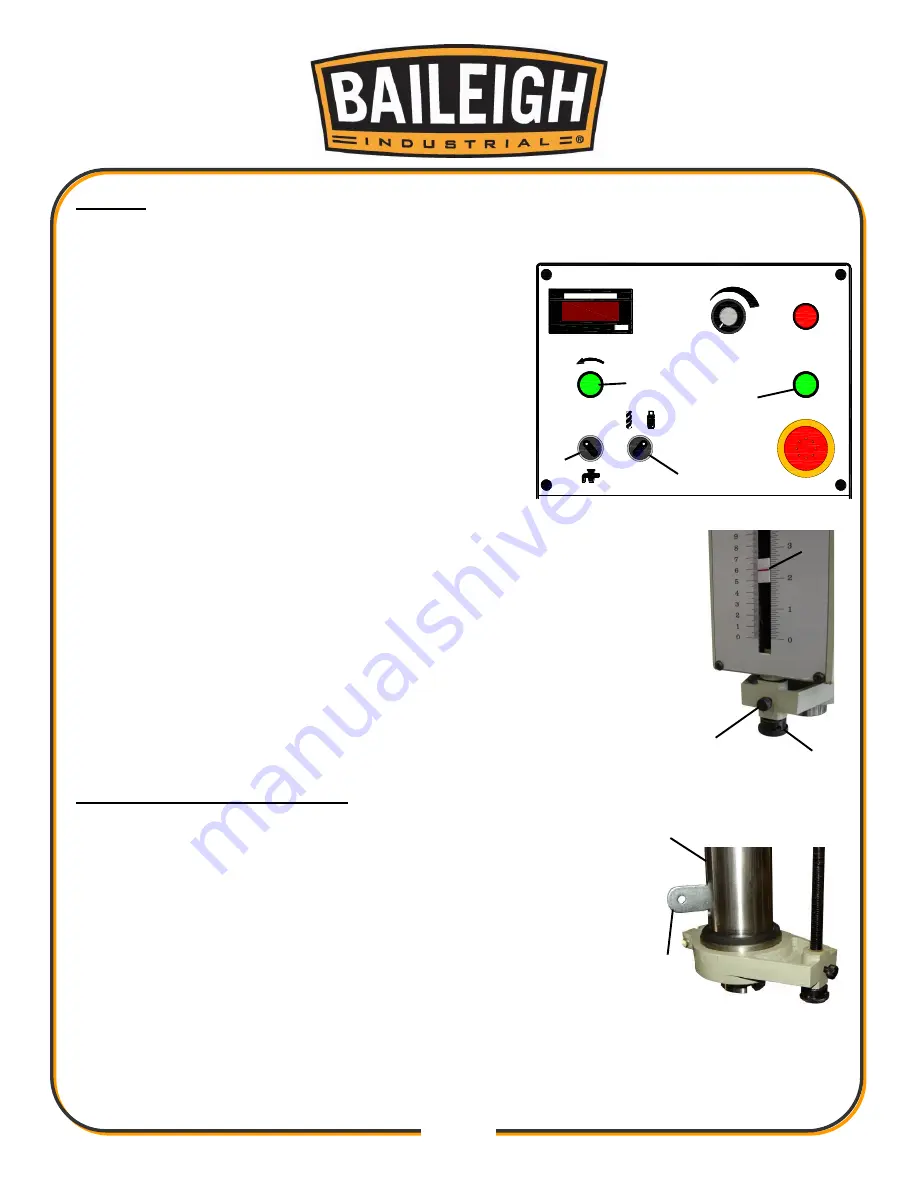

4. Selector switch (A) shown in tapping position.

5. Set the tap tool depth to zero position by lowering it

to the top surface of the piece part, using the down-

feed handles.

6. While holding the zero position, turn the depth scale

lock knob (B) counterclockwise (ccw) to release depth stop knob (C).

7. Rotate knob (C) to set the drill depth on the scale with indicator (D).

8. Tighten lock knob (B).

9. Start machine by pressing start button (E)

10. Turn on the coolant selector switch (F).

11. Begin tapping using the down-feed handles (E) to lower the chuck.

When the tap reaches the bottom of the preset depth, the spindle will

automatically reverse direction. You can also reverse the tapping

operation at any time by pressing the green reverse button (G).

Removing Tooling from Spindle

1. Disconnect machine from the power source.

2. Place a piece of wood on the table for protection.

3. Position the worktable approx

imately 10” under the bit and lower

the spindle about 6”.

4. Place the drift key (A) into the slot (B) of the quill and tap the end

of the drift key with a hammer until the bit or chuck arbor falls out.

C

B

D

A

B

DIGITAL INDICATOR

RPM

0

l

150-3000RPM

0

l

SPINDLE SPEED

E

G

F

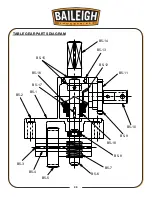

A

Summary of Contents for DP-1000VS

Page 19: ...16 16 OVERALL DIMENSIONS ...

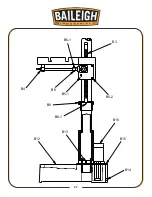

Page 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

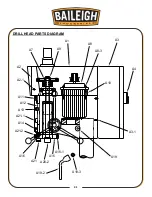

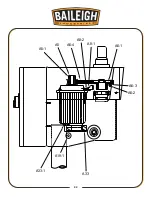

Page 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

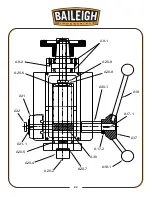

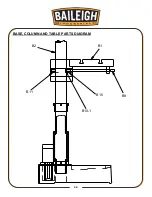

Page 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Page 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

Page 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Page 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

Page 48: ...45 45 CHUCK GUARD PART DIAGRAM ...