26

26

DRILLING RECOMMENDATIONS

Drilling Speeds

The speed of a drill is usually measured in terms of the rate at which the outer periphery of the

tool moves in relation to the work being drilled. The common term for this is Surface Feet per

Minute (SFM).

The relationship of SFM is expressed in the following formulas:

•

SFM = 0.26 X rpm X Drill Diameter (in inches)

•

RPM = 3.8 x

SFM

÷

Drill diameter (in inches)

In general, the higher the speed the shorter the drill life. Operating at the low end of the speed

range for a particular material will result in longer life.

The most efficient speed for drill operation depends upon many variables:

•

Composition and hardness of material.

•

Depth of hole.

•

Efficiency of cutting fluid.

•

Type and condition of drilling machine.

•

Desired quality of hole.

•

Difficulty of set-up.

Drilling Feed

The feed of a drill is governed by size of tool and the material drilled. Because feed rate partially

determines rate of production and also is a factor in tool life, it should be chosen carefully for

each job. In general, the most effective feeds will be found in the following ranges:

Diameter of Drill (inches)

Feed per Revolution (inches)

Under 1/8

0.001 to 0.002

1/8 to 1/4

0.002 to 0.004

1/4 to 1/2

0.004 to 0.007

1/2 to 5/8

0.007 to 0.015

Excessive Speed/Feed Indicators

•

A drill that splits up the web is evidence of too much feed or insufficient tip clearance at the

center because of improper grinding.

•

The rapid wearing away of the extreme outer corners of cutting edges indicates that speed is

too high.

•

A drill chipping or breaking out at the cutting edges indicates that either feed is too heavy, or

drill has been ground with too much tip clearance.

Summary of Contents for DP-1000VS

Page 19: ...16 16 OVERALL DIMENSIONS ...

Page 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

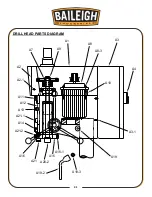

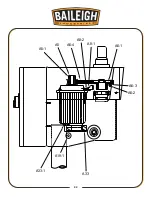

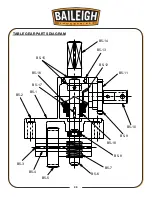

Page 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

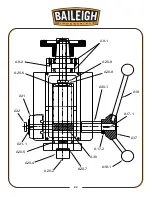

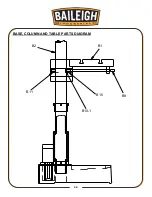

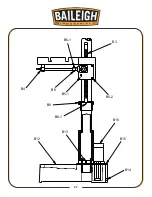

Page 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Page 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

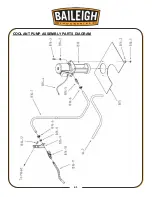

Page 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Page 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

Page 48: ...45 45 CHUCK GUARD PART DIAGRAM ...