29

29

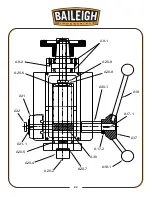

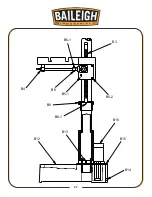

Spindle Return Spring Adjustment

The spindle return is preset by the manufacturer and should not

need adjustment.

If future attention is ever required, proceed as follows:

1. Do NOT remove spring cap.

2. Loosen screw (E) just enough to rotate spring cap (F) past pin

(Inside case. Not normally visible.) and engage pin into next

notch.

3. Rotate spring cap clockwise to decrease spring tension. Rotate

spring cap counterclockwise to increase spring tension.

4. Tighten both screws (E).

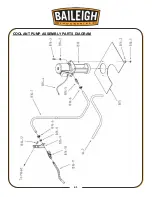

Accessing and Cleaning the Coolant System

1. Clean the drain screen.

2. Drain and wash out the dirt and debris from the reservoir

3. Replace coolant drain plug.

4. Thoroughly clean the pump and pump inlet

5. Re-fill tank with coolant solution.

The coolant system should be filled with 2 gallons of a cutting coolant.

Fill by pouring coolant into base of machine. Add coolant in the same manner when coolant is

low. Follow all coolant manufacturer’s instructions for safety, mixing and disposal.

Make sure drain hose has good, tight connection into table and that coolant flows into base.

Make sure hose leaving pump and entering ball valve has good, tight connections.

The flexible nozzle enables user to adjust coolant for each job. One ball valve controls coolant

flow to nozzle.

Oils for Lubricating Coolant

Any 10:1 (water to coolant) solution will work, however we recommend Baileigh B-Cool 20:1

(water to coolant) biodegradable metal cutting fluid. It has excellent cooling and heat transfer

characteristics, is non-flammable, and extends tool and machine life. Each gallon of concentrate

makes 21 gallons of coolant.

Drain

E

F

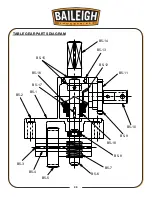

Summary of Contents for DP-1000VS

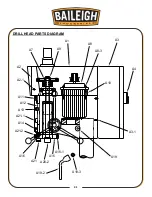

Page 19: ...16 16 OVERALL DIMENSIONS ...

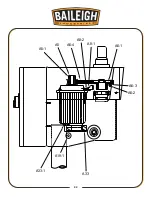

Page 20: ...17 17 GETTING TO KNOW YOUR MACHINE Q F P J B C A G H I L M E F D N O K R ...

Page 35: ...32 32 A6 2 A6 3 A6 1 A6 4 A8 1 A8 2 A5 A5 1 A33 1 A19 1 A33 ...

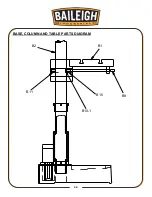

Page 39: ...36 36 BASE COLUMN AND TABLE PARTS DIAGRAM B1 B2 B11 B10 B9 B10 1 ...

Page 40: ...37 37 B3 B4 B6 1 B6 B5 1 B5 2 B8 B8 1 B12 B13 B16 B15 B14 ...

Page 44: ...41 41 COOLANT PUMP ASSEMBLY PARTS DIAGRAM ...

Page 46: ...43 43 CONTROL PANEL PARTS DIAGRAM ...

Page 48: ...45 45 CHUCK GUARD PART DIAGRAM ...